1. How can i place an order?

Please provide the details of your requirements as clear as possible. So we can send you the offer at the first time.

For further discussion, it is better to contact us with WhatsApp / WeChat / email / phone, in case of any delays.

2. What kind of display we provide?

We have laser marking machine / laser welding machine / laser cutting machine / laser cleaning / CO2 laser cutting and engraving machine / laser accessories for you choose.

3. How about the warranty?

We have 2 years warranty and lifelong maintenance.

4. What is your terms of delivery?

We accept EXW, FOB, CFR, CIF, DDU, DDP, etc. You can choose the one which is the most convenient or cost effective for you.

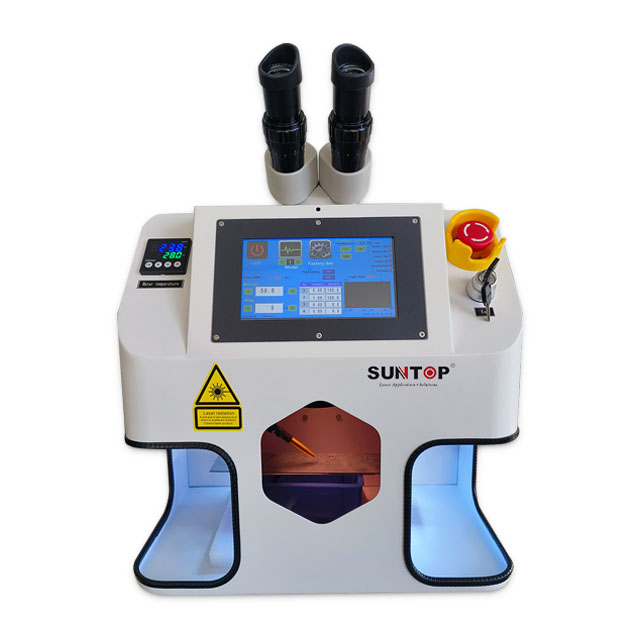

5. What is the welding quality of laser spot welding?

Laser spot welding has high welding quality, smooth and uniform welds, and provides strong connections. It is often used in the production of high-end jewelry to ensure the beauty and durability of the final product.

6. Is it difficult to operate a laser welder?

Although the principle of laser welding is complicated, modern laser spot welders are usually equipped with a user-friendly operating interface and provide detailed operating instructions, making it easy to use and suitable for operators of different experience levels.

7. What does the maintenance of a laser spot welder include?

Maintenance work includes regular inspections of the cleanliness of the laser and optical lens, ensuring the normal operation of the cooling system, monitoring the laser output power, and detecting whether the various functions of the machine are normal.

8. How long is the service life of a laser spot welder?

The service life of a laser spot welder usually depends on the frequency of use and maintenance. A high-quality machine can be used for several years or even more than ten years with good maintenance.

9. Is professional training required to use a laser spot welder?

Although the basic operation is relatively simple, it is recommended that users participate in professional training to fully understand the operation, maintenance and welding technology of the equipment to ensure safety and welding quality.

10. Does laser spot welding have a thermal effect on the metal?

Although laser spot welding has a small heat-affected zone, it may still produce some thermal effects around the weld point. Proper settings and operation can minimize this effect and ensure the structural integrity of the metal.