Laser engraving is a technology that uses high-energy laser beams to engrave and cut the surface of an object. Due to its high precision and flexibility, it is widely used in many fields. The following is a detailed introduction to laser engraving in different application areas:

1. Jewelry and metal products

Personalization: Laser engraving technology can perform fine engraving on various metal materials (such as gold, silver, platinum, etc.). Consumers can customize the name, date and specific pattern on jewelry such as rings and necklaces to meet personalized needs.

Inner engraving: Through inner engraving technology, designers can engrave in the inner space of jewelry to increase the uniqueness and emotional value of the work. For example, engrave special words on the inside of the ring.

Pattern and texture:Laser engraving can add complex patterns and textures to the surface of jewelry, making the product more beautiful and enhancing its artistic value and market competitiveness.

2. Crafts and decorations

Artworks: Artists use laser engraving to create exquisite works of art on materials such as wood, glass, and acrylic. This technology can achieve high-precision engraving and perfectly present the complexity of the design.

Creative products: Laser engraving can be used to create a variety of creative products, such as custom pendants, photo frames, etc., to provide consumers with unique decorations. Through personalized design, these works are usually highly commemorative.

3. Trophies and medals

Medal engraving: Laser engraving technology is widely used on medals and trophies in sports events, academic competitions and other fields. By finely engraving the name of the team or individual, the name of the competition and other information, the grade and value of the award are improved.

Mass production: Laser engraving can efficiently handle the production of multiple awards, especially in occasions where mass production is required, such as competitions, conferences, etc.

4. Electronic products and accessories

Labels and logos: In electronic products, laser engraving can be used to make product logos, serial numbers, and barcodes. Through laser engraving, not only can the wear resistance be improved, but also the aesthetics of the product can be enhanced.

Personalized accessories: Accessories such as mobile phone cases and headphone cases can be personalized through laser engraving, making consumers' products more unique.

5. Household items

Kitchen items: Laser engraving can be applied to kitchen utensils, such as wooden cutting boards, cups, etc. The customized design is not only beautiful, but also reflects the user's philosophy of life.

Decorations: Home decorations, such as wall art, bookshelves, lamps, etc., can be made into products with cultural and artistic expressions through laser engraving, increasing the beauty of the space.

6. Education and training

Educational tools: In schools and training institutions, laser engraving can be used to make teaching models, specimens, etc., and help students better understand concepts through precise cutting and engraving of materials.

Awards and certificates:In the field of education, laser engraving can be used to make awards, certificates, etc., to enhance their formality and beauty.

7. Manufacturing and industry

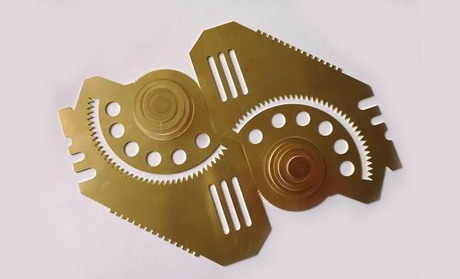

Parts identification: In factories and industrial environments, laser engraving is used to identify machine parts to ensure product traceability and quality control.

Production tools: Laser engraving can be performed on production tools to reduce reliance on labels and improve the convenience and accuracy of operation.

8. Mouse and Keyboard Personalization

Personalized appearance:Computer accessories such as mice and keyboards can be personalized through laser engraving technology to increase the appeal of the product, especially for e-sports and game players. This personalized design is particularly popular.

Laser engraving technology has become the preferred processing method in many industries due to its high precision and flexibility. Whether it is artistic creation or personalized customization of goods, laser engraving can provide a solution.Click here to contact Suntop Laser now to provide a customized laser engraving machine according to your needs.

Advantages of Laser Engraving Laser engraving technology has many advantages that make it stand out among many engraving methods. The following is a comparison with other engraving methods and related introductions to ensure the long-term preservation of engraved works.

| Advantages of laser engraving:

1. High precision and detail

Laser engraving can achieve extremely high precision and can realize complex and detailed designs. The diameter of the laser beam is very small, usually in the range of a few microns, and can engrave fine patterns and text, surpassing the capabilities of traditional mechanical engraving and hand engraving.

2. Flexibility

Laser engraving can easily handle a variety of materials, including wood, metal, plastic, acrylic, glass, etc. Other engraving methods usually require specific tools and techniques and can only be applied to certain materials.

3. No mold required

Compared with traditional cutting and engraving techniques, laser engraving does not require mold making and can be processed directly according to computer design drawings. This greatly shortens the production cycle and reduces the initial investment cost.

4. Less material waste

Laser engraving uses a non-contact engraving method to reduce material waste. At the same time, the precision of laser cutting means less post-processing, making material utilization more efficient.

5. Repeatability

Laser engraving is very consistent in the production process, allowing each product to maintain the same quality and design when mass-produced. This is very important for commercial production.

6. Automation and modernization

Laser engraving can usually be combined with a computer control system to realize the automation of production, improve production efficiency and management level.

| Advantages compared to other engraving methods

Traditional engraving:such as wood carving or stone carving (manual method), usually requires a high level of technology and experience, and is slow, costly, and difficult to achieve complex designs. Laser engraving can be quickly realized with only computer design.

Mechanical engraving:such as CNC engraving, although relatively accurate, requires a long processing time and is limited by mechanical structure. Laser engraving is more flexible and can handle more complex patterns.

Chemical etching:involves the use of chemicals, which may pollute the environment; while laser engraving is a cleaning process that is controlled by calculation and program.

| How to ensure the long-term preservation quality of engraved works

In order to ensure the long-term preservation quality of laser engraved works, the following methods can be taken:

1. Choose the right material

Choosing durable materials for laser engraving is the key. For example, choosing high-quality wood (such as mahogany, oak), metal (such as stainless steel, aluminum) or special plastics can enhance the shelf life of the work.

2. Surface treatment

Surface treatment of the sculpture can effectively improve its wear resistance and corrosion resistance:

Painting or coating: Apply protective paint or clear coating to the surface of wood or metal to prevent oxidation and corrosion and enhance the appearance.

Waterproofing: For materials that are susceptible to moisture, waterproofing can prevent damage caused by moisture.

3. Storage conditions

Ensure that the sculpture is stored in a suitable environment:

Avoid direct sunlight: Excessive light may cause the material to fade, so avoid placing the work in direct sunlight.

Control humidity and temperature: Maintain appropriate humidity and temperature to avoid the impact of extreme environments on the material.

4. Regular cleaning and maintenance

Clean the sculpture regularly to avoid the accumulation of dust and dirt. Wipe gently with a soft cloth and avoid using chemical cleaners to avoid damage.

5. Block contact substances

Avoid direct contact of engravings with chemicals, grease and other contact substances that may cause material degradation, such as perfumes, detergents, etc.

Laser engraving has gradually become the preferred engraving method due to its high precision, flexibility, automation and other advantages, and is more competitive than traditional methods and mechanical methods. In order to ensure the long-term preservation quality of laser engraving works, reasonable selection of materials, appropriate surface treatment, reasonable storage and regular maintenance are essential measures. Through these methods, the service life of engraving works can be effectively extended to maintain their beauty and functionality. Click here to contact Suntop Laser now for more details on laser engraving.

Laser engraving works are widely used in many fields such as artistic creation, commercial logo, personalized gifts, etc. due to their unique precision and design flexibility. Its durability is not only derived from the quality of the materials used, but also closely related to maintenance and storage conditions. Through reasonable selection and post-processing, the durability and appearance of laser engraving works can be significantly improved.