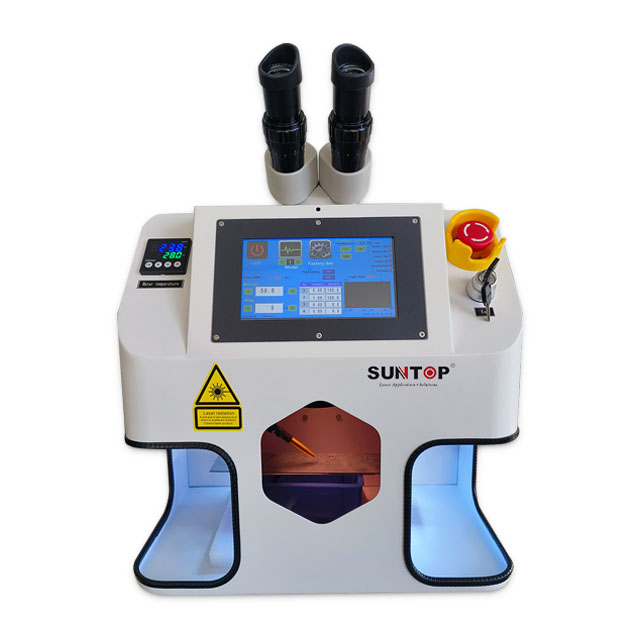

Q1: What is a desktop mini jewelry laser welder?

A1: Desktop mini jewelry laser welder is a small laser device dedicated to jewelry manufacturing and repair. It is capable of welding metal parts with high precision and is suitable for delicate jewelry crafts such as welding rings, earrings and necklaces.

Q2: What materials of jewelry is this laser welder suitable for?

A2: Desktop mini jewelry laser welder is suitable for precious metals such as gold, silver, and platinum, as well as materials with high hardness such as diamonds and gemstones.

Q3: Does the power of the laser welder affect the welding effect?

A3: Yes, higher-power laser welders can provide stronger welding energy and are suitable for welding larger-sized jewelry pieces, while lower-power models are suitable for welding small jewelry.

Q4: What safety precautions should be taken when using a laser welder?

A4: Wear goggles: protect your eyes from laser damage.

Good ventilation: Fumes are generated during welding, so make sure the work area is well ventilated.

Keep the surroundings clean: avoid flammable materials near the welding area to ensure safety.

Q5: How to maintain the desktop mini jewelry laser welder?

A5: Regular cleaning: Keep the inside and outside of the equipment clean, and clean the optical path and workbench regularly.

Check the laser fiber: Make sure the fiber is not damaged and check the connection part regularly.

Software update: Update the equipment software as needed to ensure optimal performance.

Q6: What are the advantages of laser welding compared to traditional welding methods?

A6: Accuracy: Laser welding can achieve higher welding accuracy and can handle tiny details.

Small heat-affected zone: Laser welding only heats the welding point, reducing the thermal impact on the surrounding materials and reducing the risk of deformation.

Fast welding speed: Laser welding is faster and improves production efficiency.

Q7: What is the price of a mini jewelry laser welding machine?

A7: The price of a mini jewelry laser welding machine varies depending on factors such as brand, power, and function, generally ranging from thousands to tens of thousands of dollars. It is recommended to choose a suitable model according to actual needs before purchasing.

Q8: How can i place an order?

A8: Please provide the details of your requirements as clear as possible. So we can send you the offer at the first time. For further discussion, it is better to contact us with WhatsApp / WeChat / email / phone, in case of any delays.

Q9: How about the warranty?

A9: We have 2 years warranty and lifetime maintenance.

Q10: What is your terms of delivery?

A10: We accept EXW, FOB, CFR, CIF, DDU, DDP, etc. You can choose the one which is the most convenient or cost effective for you.