CO2 laser cutting technology has been a game-changer in various industries, including the mobile phone screen protector sector. This advanced method utilizes a high-powered laser beam to precisely cut through materials with exceptional speed and accuracy, making it ideal for the production of custom-designed screen protectors with intricate patterns and shapes.

CO2 laser cutting technology has revolutionized the cell phone film industry, offering a range of advantages that enhance efficiency and quality. In this article, we will delve into the various benefits of CO2 laser cutting in the cell phone film industry and explore how this technology is reshaping the manufacturing process.

Requirements for precision cutting in the cell phone industry:

The precise technical requirements for cutting cell phone films have led manufacturers to adopt laser cutting technology. At present, CO2 laser cutting technology is the most cost-effective laser cutting technology on the market. The use of advanced CO2 laser, excellent optical modulus and optical path design, the formation of a more perfect spot, reducing the heat-affected zone, can cut out high-quality cell phone film products.

With the continuous development of Suntop Laser technology, its advanced CO2 laser technology, fast speed, high precision, safe and reliable, good cutting quality, high quality, stable performance; compared with the industry, there are a variety of unique technical advantages. With ± 0.005mm repeat positioning accuracy, ± 0.05mm comprehensive processing accuracy, the use of advanced imported CNC system, to ensure high-quality process production, to meet the requirements of precision processing of various types of cell phone film, is an expert in the field of laser precision processing.

Features of CO2 laser cutting machine:

1. adopting high intelligent control system, automatic control, high positioning accuracy, smooth molding edge, no burr, no need for secondary processing.

2. Non-contact processing, no damage to the material itself, ensuring the highest cutting quality of the material and enhancing the competitiveness of the manufacturer.

3. one-piece frame structure design, durable, stable long-term operation, suitable for large quantities, multiple varieties, high-speed, high-precision continuous production of industrial processing site.

4. The machine complies with European CE safety standards, equipped with sensor door, automatic stop when the laser is turned on accidentally.

5. Adopt professional laser cutting software, perfectly support dxf, plt and other format files import, easy data processing, interface operation humanization.

In addition to being used in the cell phone film industry, Suntop Laser's CO2 laser technology can also be used for PC film, PET film, PP film in the communication, computing, netcom, cloud server and other industries. It can be used for non-metallic materials such as plastic, acrylic, jade, crystal, rubber, leather, organic glass and so on.

Advantages of CO2 laser cutting in cell phone film industry:

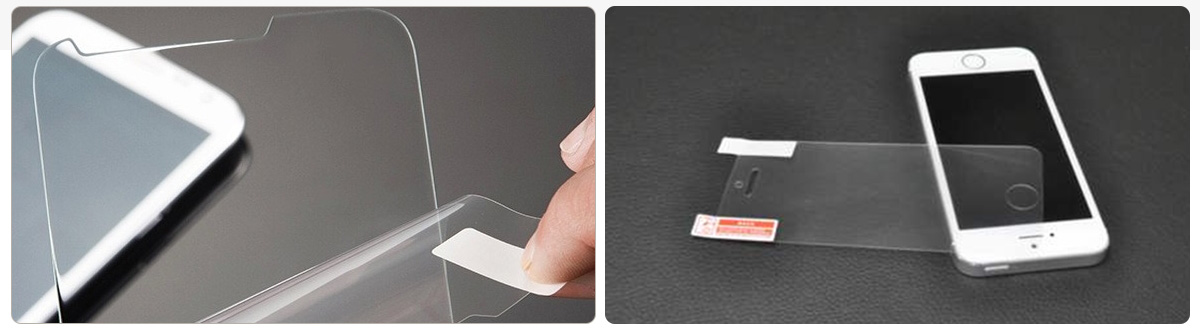

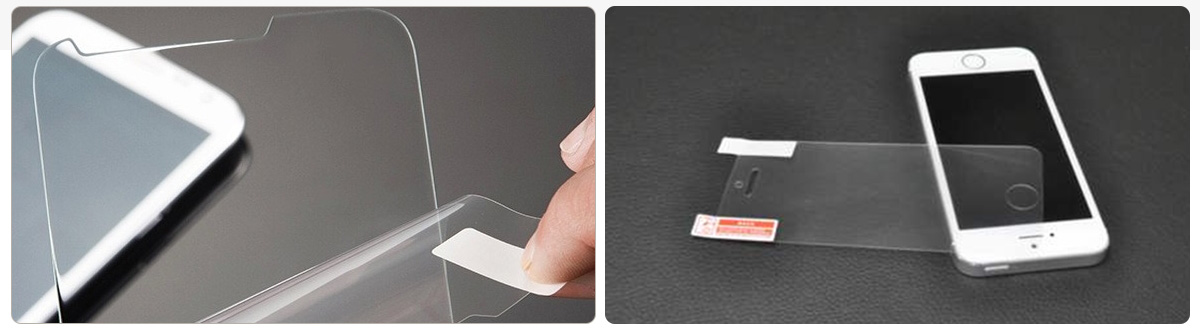

● Precision Cutting: CO2 laser cutting offers unmatched precision in cutting mobile phone screen protector materials such as tempered glass and PET film. This precision ensures that the screen protectors fit perfectly on various phone models, providing optimal protection against scratches and cracks.

● Customization Options: The flexibility of CO2 laser cutting allows for the customization of screen protectors to meet specific design requirements. Manufacturers can easily create unique patterns, logos, or text on the protectors, catering to the diverse preferences of consumers in the competitive mobile phone accessory market.

● Efficiency and Cost-Effectiveness: CO2 laser cutting is a highly efficient process that significantly reduces production time compared to traditional cutting methods. This efficiency not only increases productivity but also lowers manufacturing costs, making it a cost-effective solution for large-scale production in the mobile phone screen protector industry.

● Environmental Sustainability: The use of CO2 laser cutting technology in the production of screen protectors promotes environmental sustainability. Unlike traditional cutting methods that generate waste and require harmful chemicals, laser cutting is a clean and eco-friendly process that minimizes material wastage and reduces the industry's carbon footprint.

● Enhanced Product Quality: The precise and clean cuts achieved through CO2 laser cutting result in high-quality screen protectors that offer superior clarity and touch sensitivity. This quality assurance helps manufacturers deliver premium products that meet the stringent standards of mobile phone users seeking durable and reliable screen protection.

● Market Competitiveness: By leveraging CO2 laser cutting technology in the production of mobile phone screen protectors, manufacturers can stay ahead of the competition in a rapidly evolving market. The ability to offer customized, high-quality products efficiently positions companies for success and customer loyalty in the competitive smartphone accessory industry.

In conclusion, the integration of CO2 laser cutting technology in the mobile phone screen protector industry has revolutionized the way screen protectors are manufactured and customized. With its precision, efficiency, customization options, and environmental benefits, CO2 laser cutting is driving innovation and setting new standards for quality in the smartphone accessory market.