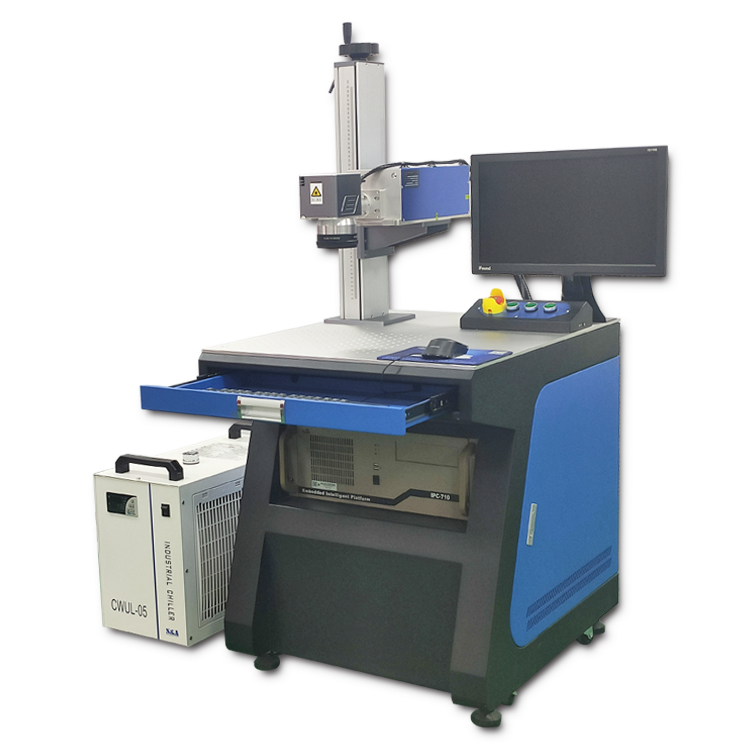

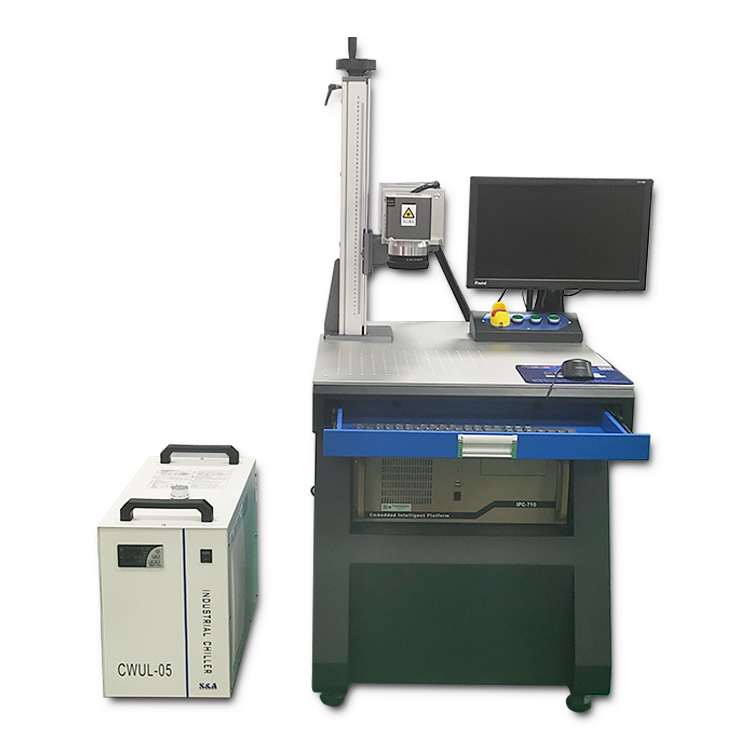

Details Product Parameters Samples Video

Features of laser marking machine for glass

1. The beam quality is good and the focus spot is small, which can realize ultra-fine marking.

2. The heat-affected area is extremely small, avoiding deformation, damage or burning of the processed material, and the yield is high.

3. Adopt built-in laser diode technology to avoid the influence of fiber jitter on the output laser.

4. High photoelectric conversion rate, 355nm output wavelength, beautiful engraving effect, good touch feeling and high anti-counterfeiting effect.

5. According to the customer's actual product laser marking requirements, select other optional accessories, such as rotating device, 2D/3D workbench, pen turntable and other fixtures.

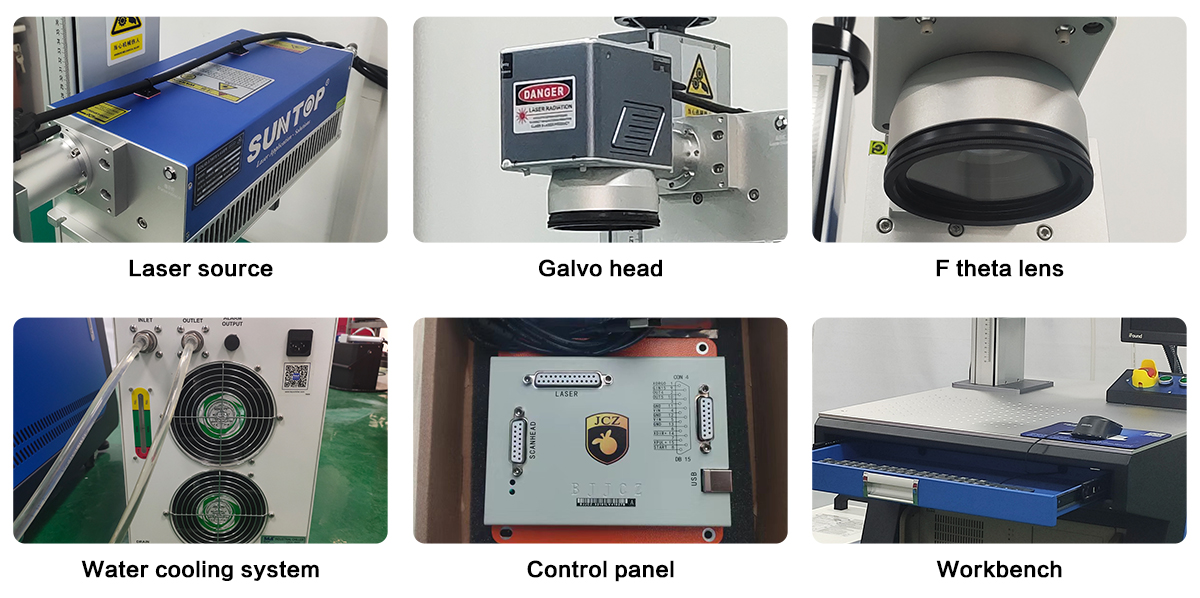

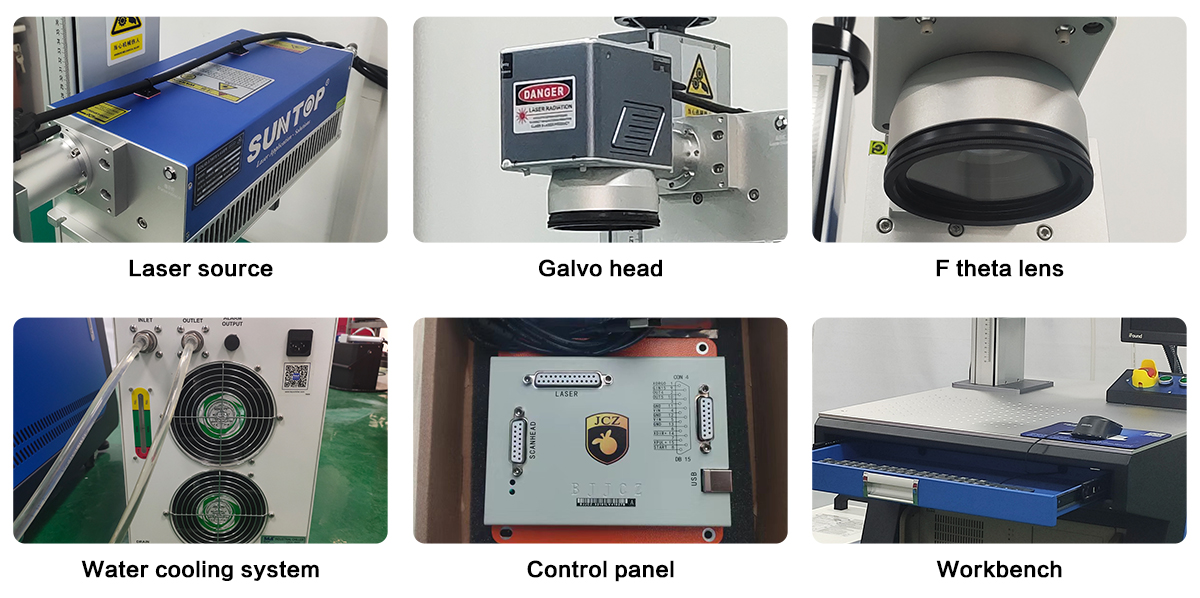

Details of laser marking machine for glass

1. Laser source

Adopt high quality UV light source, high beam quality, good stability, high efficiency and long life.

2. Galvo head

Good stability, anti-jitter, high positioning accuracy, fast marking speed, strong anti-interference ability.

3. F theta lens

The highest light transmittance guarantees no power reduction, Suntop original product.

4. Water cooling system

Water cooling system is adopted to accelerate heat dissipation. Protect the host computer to ensure the machine runs for a long time.

5. Control panel

BJJCZ brand original EZCAD control system has the characteristics of high stability, easy operation and good performance.

6. Aluminum plate workbench

The whole workbench is made of high quality aluminum plate, distributed with multiple groups of positioning holes, compact interface, flexible adjustment of product position, easy to use.

Advantages of laser marking machine for glass

1. High marking precision, fast speed, clear text pattern, uniform, durable, low power consumption.

2. Stable performance, no consumables, low cost of use, and maintenance-free.

3. Non-contact processing, no damage to the product, no tool wear, good marking quality.

4. The heat-affected area is very small, there will be no thermal effect, and the material will not deform or burn.

5. It can be integrated on the production line to mark the production date, S/N number, etc.

6. Widely used in micro-machining, fine engraving of various metal and non-metal film materials.

Laser marking machine for glass application

Application materials

It is suitable for almost all materials. Widely used in metal (all metals such as iron, copper, aluminum, magnesium, zinc, etc.), glass, crystal, PCB, plastic, fiber, paper, paint, silicon wafer, LCD, polyamide, wire, plug and other polymer materials.

Application industry

Especially suitable for the high-end market of ultra-fine processing, skin care cosmetics, medical drugs, food, silicon wafer micro-hole, blind hole processing, glass products, metal products, plastic buttons, electronic components, gifts, communication equipment, building materials, etc.

Parameters of laser marking machine for glass

Model | ST-UV03 | ST-UV05 |

Laser Power | 3W | 5W |

Max. marking range | 110*110mm | 150*150mm |

Output power | >3W@30KHZ | >5W@40KHZ |

Maximum pulse energy | 0.1MJ@30KHZ | 0.12MJ@40KHZ |

Pulse duration | <15NS@30KHZ | <18NS@40KHZ |

1/e2 beam diameter at output | 0.7mm | 0.8mm |

Laser Type | UV laser |

Laser source | GAIN (JPT and other brand optional) |

Control Software | EZCAD |

Cooling Mode | Water Cooling |

Beam diameter | ≤ 10mm |

Working Accuracy | ±0.002MM |

Marking Speed | 1-12000mm/s |

Repetition Frequency | 20-100KHz |

Laser Wavelength | 355nm |

Minimum Font for Marking | 0.01mm |

Working Voltage | 220V+10% 50/60 Hz |

Graphic Format Supported | AI, PLT, DXF, BMP, DST, DWG, DXP |

Applicable Material | all metal material and all non metal material |

Spare Parts Come with the Machine | Protective glasses, Metal business card, Foot switch, Hex socket wrench, Power cord |

Optional Accessories to Purchase | D80 Rotating Shaft/ D57 Small Chuck/2D Table (X.Y direction)/ Cutting Fixture |

Net Weight (KG)/ Gross Weight | 150KG / 180KG |

Packaging Dimension | 1160mm*900mm*1680mm (L*W*H) |