Details Product Parameters Samples Video

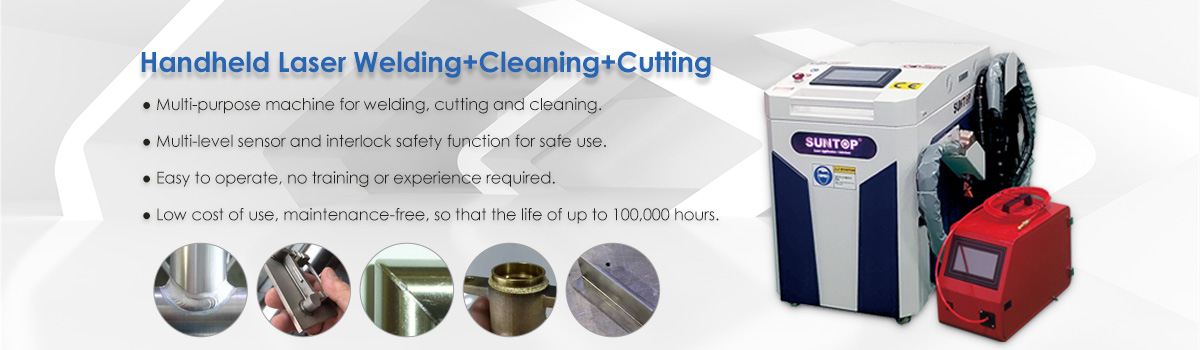

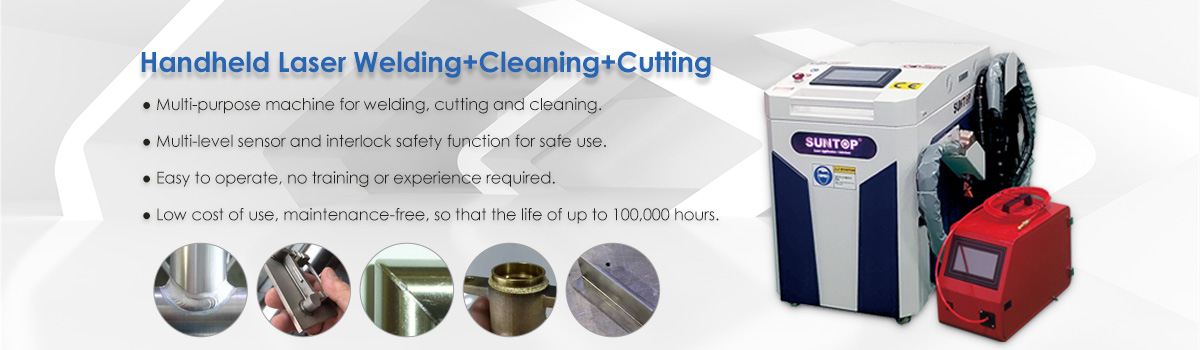

Features of 1500w laser cleaning machine

1. Flexible and easy to operate, can meet multi-angle and multi-position welding and cleaning.

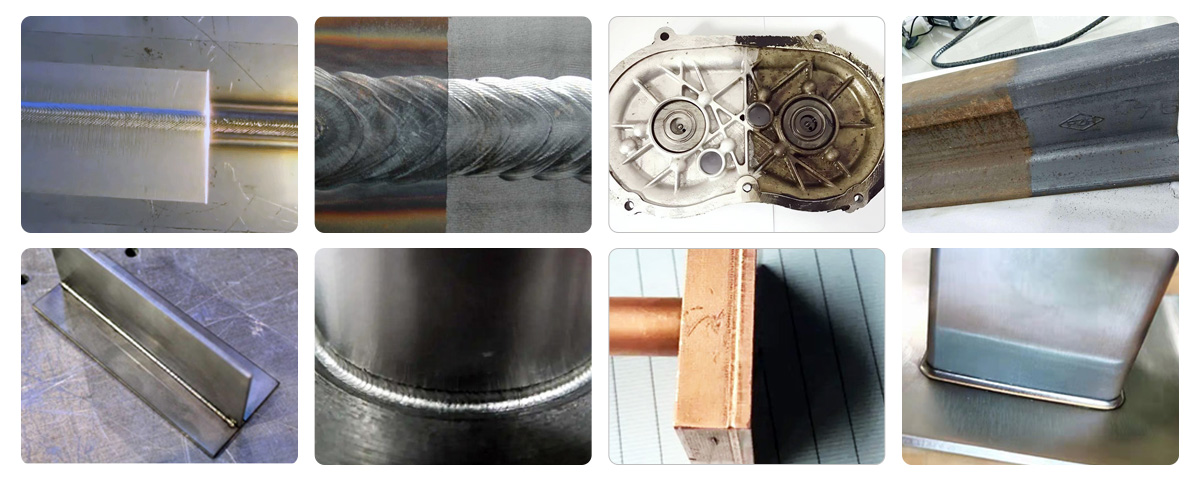

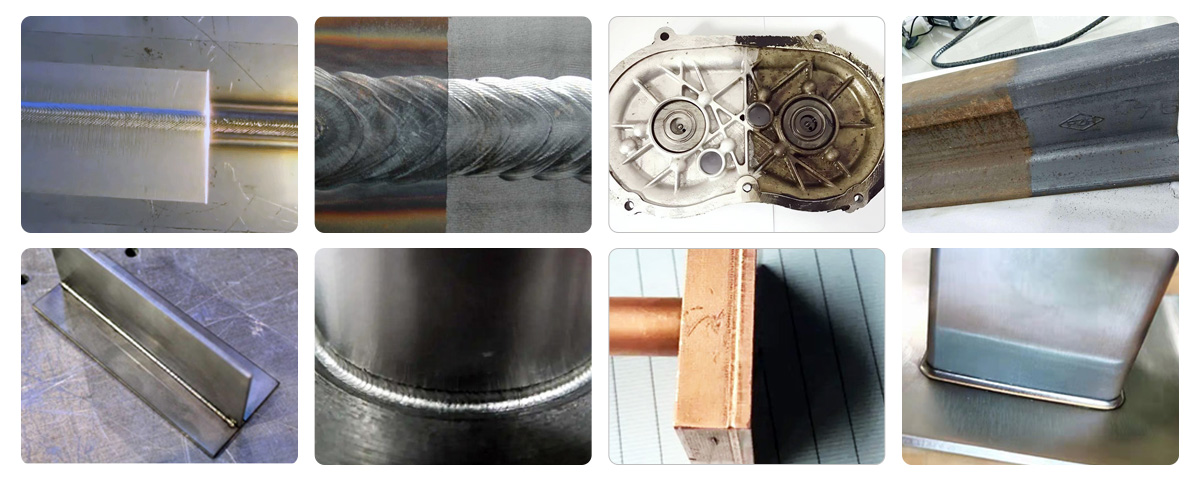

2. It can be used to weld metal parts of different materials, such as steel and aluminum alloy. Laser welding is characterized by a small heat-affected zone and good weld quality, which allows for high-strength welded connections.

3. It can be used to clean the surface of the workpiece. By adjusting the parameters of the laser beam, the dirt and oxidized layer on the surface of the workpiece can be removed to restore its original finish and brightness.

4. Equipped with the original fiber optic cable with a length of 10 meters, thus overcoming the limitations of the workbench space, it can realize outdoor welding and cleaning and long-distance welding and cleaning.

5. The machine has several safety alarm functions, the welding copper nozzle is only effective when it touches the metal and the safety clip clamps the metal plate, and the welding copper nozzle will automatically lock the light when it moves away from the workpiece. The high safety of the machine guarantees the absolute safety of the operator during work.

Details of 1500w laser cleaning machine

1. Laser cleaning head

The light weight is only 0.8KG, flexible and convenient to weld metal parts of any shape, the weld width is adjustable, and it can perform long-distance welding with a length of 10 meters. With security monitoring system.

2. Operation interface

Advanced resistive touch screen with higher sensitivity, intelligent control, can store multiple welding parameters, support multiple languages (English, Spanish, German, Italian, French, Russian, Turkish, etc.)

3. Automatic wire feeding system

Touch screen design, automatic wire filling, fully digital design, support 0.8mm, 1.0mm, 1.2mm, 1.6mm, 2.0mm diameter stainless steel and aluminum wires.

4. Laser source

We use a customized 45um core diameter welding fiber laser with a lifespan of 100,000 hours, maintenance-free, and can weld various metals.

5. Water chiller

Double circulating water cooling makes the laser source and welding head cool better, and the temperature control sensor adopts imported brands.

Advantages of 1500w laser cleaning machine

1. Flexible and easy to operate, can meet multi-angle and multi-position welding and cleaning.

2. It can be used to weld metal parts of different materials, such as steel and aluminum alloy. Laser welding is characterized by a small heat-affected zone and good weld quality, which allows for high-strength welded connections.

3. It can be used to clean the surface of the workpiece. By adjusting the parameters of the laser beam, the dirt and oxidized layer on the surface of the workpiece can be removed to restore its original finish and brightness.

4. Equipped with the original fiber optic cable with a length of 10 meters, thus overcoming the limitations of the workbench space, it can realize outdoor welding and cleaning and long-distance welding and cleaning.

5. The machine has several safety alarm functions, the welding copper nozzle is only effective when it touches the metal and the safety clip clamps the metal plate, and the welding copper nozzle will automatically lock the light when it moves away from the workpiece. The high safety of the machine guarantees the absolute safety of the operator during work.

1. The laser cleaning torch is hand-held, comfortable to hold, and can flexibly cope with a variety of objects and angles.

2. The operation is simple and easy to learn quickly, no technical threshold requirements for operators, ordinary workers can be on duty after a short training operation, can easily achieve high-quality welding, cleaning effect.

3. fully enclosed optical path design, according to the principle of laser science, their own design, more reasonable structure, dustproof, good heat dissipation, effectively extend the service life of the machine parts.

4. Suntop's patented technology water circulation protection system and auxiliary gas detection effectively extends the life of the laser lens and prevents damage to optical components caused by Improper operation.

5. Infrared positioning verifies the position of the weld head, verifying the position during the welding process. The welding position is more accurate, the weld seam is smooth and beautiful, easy to grind and polish, no need for post-weld treatment or just simple treatment.

Single side weld thickness

Maximum melting | 1500W | 2000W | 3000W |

Stainless steel (mm) | 0.5-4 | 0.5-5/6 | 0.5-6/7 |

Mild steel (mm) | 0.5-4 | 0.5-6 | 0.5-7/8 |

Aluminum (mm) | 0.5-3 | 0.5-4 | 0.5-5 |

Brass/copper (mm) | 0.5-2 | 0.5-2.5 | 0.5-3 |

Galvanized sheet (mm) | 0.5-4 | 0.5-5/6 | 0.5-6/7 |

Iron (mm) | 0.5-4 | 0.5-6 | 0.5-7/8 |

Remark: Double weld thickness can be achieved if the material is welded from both sides in two times.

Cleaning ability (only for reference)

Power/W | Material | Cleaning speed | Effective beam/cleaning range | Depth of cleaning | Cleaning efficiency (cu.m./H) |

1500 | floating rust | 50mm/S | 150mm | 20um | 15 |

Paint | 50mm/S | 150mm | 100um | 6 |

Rusting | 50mm/S | 150mm | 120um | 4 |

2000 | floating rust | 50mm/S | 300mm | 20um | 20 |

Paint | 50mm/S | 300mm | 100um | 8 |

Rusting | 50mm/S | 300mm | 120um | 5 |

3000 | floating rust | 50mm/S | 300mm | 20um | 30 |

Paint | 50mm/S | 300mm | 100um | 14 |

Rusting | 50mm/S | 300mm | 120um | 9 |

Handheld head

● Independent research and development, set up multiple security alarms, simple and flexible operation.

● Visualize all parameters, monitor the status of the whole machine in real time, avoid problems in advance, facilitate troubleshooting and solve problems, and ensure the stable operation of the system.

● All process parameters can be set, and various process effects can be tested flexibly.

Safety features

ST-FW1500H/2000H/3000H is a Class IV laser system and routine precautions are required for the safe operation of the equipment.

Built-in features include:

● Key switch control of laser source and Emergency-stop button ensure deliberate operation.

● Fiber laser interlock verifies integrity of laser delivery to the welding gun.

● Laser weld gun trigger, enable and then fire, for intentional operation.

● Part contact electrical interlock turns off the laser power if the welding head is not in contact with the welded parts.

Operators must wear all recommended personal protective equipment (PPE), including laser safety glasses, laser and heat resistant gloves, hats, leather aprons, etc., and other laser and heat resistant clothing.

Application materials

Suitable for welding stainless steel, carbon steel, copper, aluminum, gold, chromium, silver, titanium, nickel and other metals or alloys. It can also be used for various welding between different materials, including copper – brass, titanium-molybdenum, titanium- gold, nickel-copper, etc.

Suitable for removing resin, paint, oil stains, stains, dirt, rust, coatings, etc. from the surface of objects.

Application industry

Widely used in aviation, machinery manufacturing, hardware, building materials, chassis and water tanks, mold machinery, decoration and advertising, kitchen utensils and sanitary ware, doors and windows, door frames, electronic and electrical appliances, household goods, sheet metal processing, automobile parts and other related fields.

Parameters of 1500w laser cleaning machine

Max. welding thickness (mm) | ≤3 | ≤5 | ≤8 |

Max. welding seam width (mm) | 5 | 5 | 8 |

Laser type | Fiber laser (Suntop custom 20um welding exclusive) |

Laser detection method | Bluetooth wireless connection, Mobile App Monitoring |

Control panel language support | English, Spanish, German, French, Turkish, Italian, Russian, Vietnamese, Thai, Korean, Japanese, etc. |

Laser wavelength (nm) | 1064+5 |

Suitable welding materials | Carbon steel, stainless steel, aluminum, galvanized sheet metal, brass, iron and other metal materials |

Adapted welding methods | Spot welding, overlap welding, splice welding, fillet welding, lap welding etc. |

Laser power adjustment range (%) | 10-100 |

Cooling method | Advanced water-cooling, dual temperature control and automatic control |

Welding aiming preview method | Built-in Red-Light pointer |

Protection systems | Air pressure sensor and solenoid valve control |

Length of fiber optic cable (meter) | Standard 10 (can be customized 15) |

Welding shielding gas | Argon or nitrogen (air pressure approx. 6-8 bar) |

Working environment | Temperature 5-45 °C /humidity 10-90% |

Other optional support functions | Cleaning + cutting | Cleaning + cutting | Cleaning + cutting + weld bead cleaning |

Max. Cutting thickness (mm) | 1.2 | 1.5 | 2 |

Max. cleaning width (mm) | 40 | 40 | 120 |

Automatic wire feeder type (Universal with TIG wire)

| Single wire feed | Single wire feed | Support both the double wire feed and single wire feed |

Solid wire type (SS, Iron, AL, Brass) | 0.8, 1.0, 1.2, 1.6 | 0.8, 1.0, 1.2, 1.6 | 0.8, 1.0, 1.2, 1.6, 2.0, 2.5 |

Temperature control monitoring alarm | Yes | Yes | Yes |

Main machine consumables | Laser protective lenes, welding nozzles, welding wires |

Machine size (MM) | 686*425*611 | 750*1080*1000 | 750*1080*1000 |

Machine net weight (KG) | 110 | 220 | 240 |

Power supply requirement | 110V / 220V±10%, single phase | 380V±10%, three phase |

Total power consumption (Maximum) | 3500W | 4500W | 7000W |