Details Product Parameters Samples Video

Visual marking systems of precision laser markings

1. Supports carbon dioxide, optical fiber, ultraviolet, green light and other lasers. Supports automated marking of static, large format, conveyor lines and assembly lines.

2. The software interface is rich in functions. Users can set the interface according to their own needs and support multiple languages.

3. Experienced hardware and software engineers can select camera lenses and secondary development of software based on materials and needs.

4. The camera positioning accuracy is 0.02mm; one-click automatic calibration; multi-mode and multi-target marking at the same time; the marking content can be fixed or changed.

Advantages of precision laser markings

● High-precision vision system

Use high-resolution industrial cameras to capture dynamic images of workpieces in real time. To confirm the coordinate changes of the dynamic workpiece.

Automatically move the offset coordinates to the correct position through calculation and mark at the correct position.

● Save processing cycle

The fiber vision laser marking machine improves the marking accuracy of products such as fixtures that are complex and costly to make, small sizes or irregular products that are difficult to control.

The location of the product affects the marking accuracy and other shortcomings, which greatly shortens the marking cycle.

●Automated flow marking

The self-owned software algorithm has high positioning accuracy and fast response speed. It can be used with the conveyor belt to load the entire tray to achieve efficient marking on the assembly line.

● High-speed area scan camera

With high-speed area array industrial cameras, the image acquisition speed can reach more than 100 frames. The camera has a large imaging field of view and is suitable for marking any area product.

● High-precision marking effect

Actively locate the angle and position of the target product to achieve precise marking without re-marking or missing marks.

According to the visual configuration of the product, the marking accuracy can be controlled within 0.02mm.

Visual positioning system features of precision laser markings

1. One-click automatic calibration to associate laser and visual coordinates;

2. One-click distortion correction is suitable for occasions that require high-precision positioning and marking. Use a visual lens to correct the workpiece coordinates;

3. Diversified marking target support, single mode single target/single mode multi-target/multi-mode multi-target;

4. The marking information can be fixed or changed (supports communication access, ASCII conversion, binary and hexadecimal and other modes);

5. Communication support: IO, TCP/IP, RS232, RS485 and other protocols;

6. Multi-template product management makes it easy to switch between different products. Image follow mode;

7. The camera has a large imaging field of view and is suitable for marking any flat product;

8. The camera can automatically identify and mark products at any angle and in any quantity;

9. Can be integrated with laser light paths of various wavelengths such as optical fiber, CO2, ultraviolet, etc.;

10. Through motion guide rail control, splicing and marking of large-format products can be realized;

11. It occupies a small space and does not occupy any space on the working platform. The existing laser installation space can be upgraded;

12. XYZ axes can be added according to actual product characteristics to achieve fully automated visual positioning marking.

Application materials of precision laser markings

Suitable for working with most metal marking applications such as Gold, Silver, Stainless Steel, Brass, Aluminum, Steel, Iron Titanium etc., and can also mark on many nonmetal materials, such as ABS, Nylon, PES, PVC etc.

Application industry of precision laser markings

KBC Industrial, cooking utensils, tools, lC, auto parts, Lamp bubble parts, LED plastic parts, Machine parts, Target automobiles sectors, knives, cylinder metal parts, Jewelry, luggage buckle, electronic industry, lC industrial, hardware industry, sanitary ware industry, food packing industrial, etc.

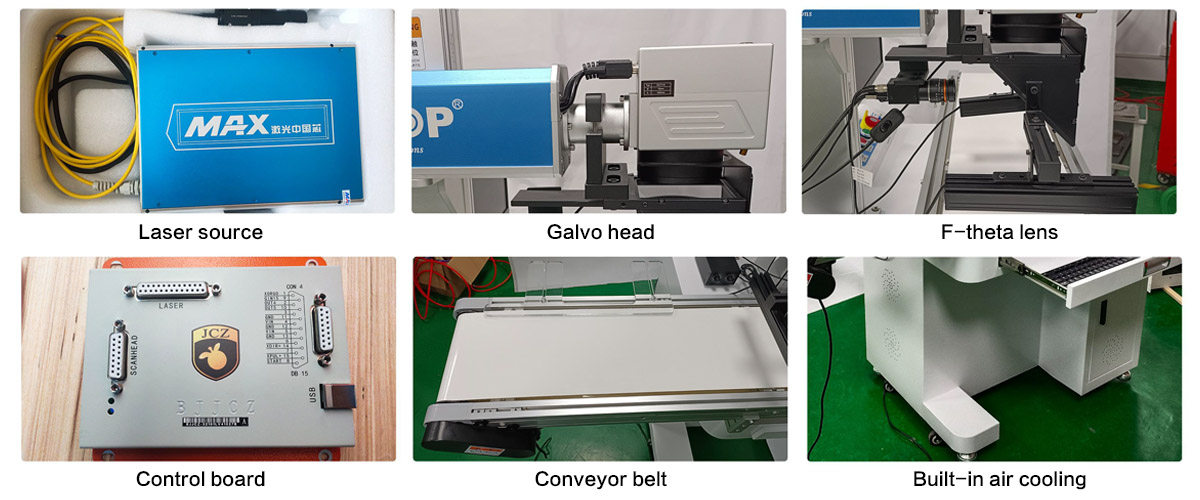

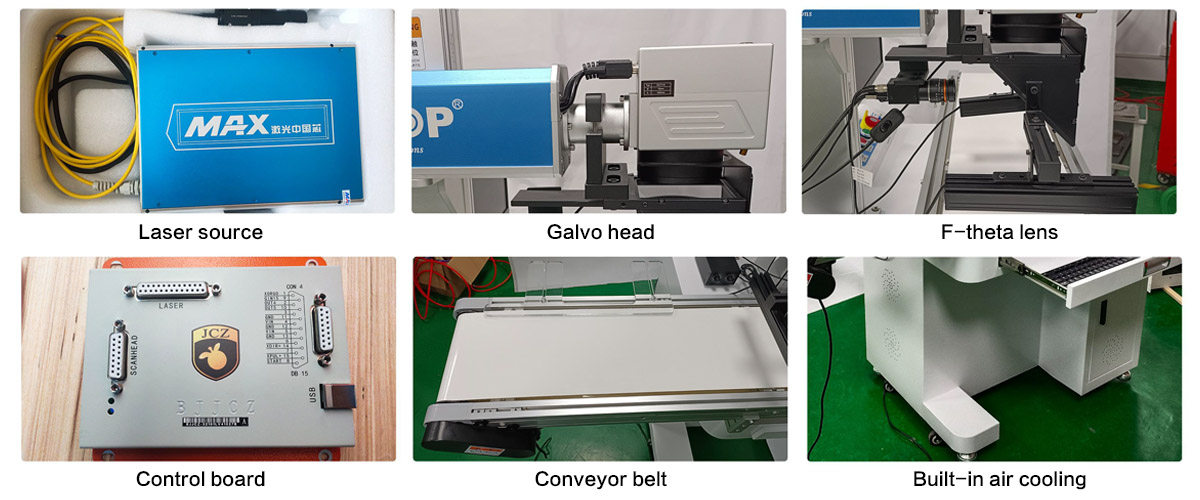

Parameters of precision laser markings

Model | ST-FL20V/30V/50V/70V/100V |

Laser power | 20W/30W/50W/70W/100W |

Marking area | 1110*110/175*175/200*200/300*300mm |

CCD visual range | 120mm |

Laser wavelength | 1064nm |

Working accuracy | ±0.002mm |

Marking Depth | 0-0.5mm |

Minimum font for marking | 0.15mm |

Minimum character | 0.2mm |

Marking speed | 0-7000mm/s |

Operating system | Win7 and Win10/32 bit and 64 bit |

Laser source | MAX Brand (Raycus can be choose) |

Repetition frequency | 20-100KHz |

Cooling mode | Air Cooling |

Graphic format supported | AI, PLT, DXF, BMP, DST, DWG, DXP |

Environmental requirements | Temperature: 10-35℃, Humidity: 5-75% |

Working voltage | 220V±10% 50/60 Hz |

Applicable material | All metal (Stainless steel, Carbon steel, Brass, etc.) and some plastic (ABS, PVC, PES, ETC.) |

Optional Accessories to Purchase | D80 Rotating Shaft/ D57 Small Chuck/2D Table (X.Y direction)/ Cutting Fixture |

Net weight/gross weight (KG) | 140KG / 168KG |

Machine dimension | 800*600*1400mm (L*W*H) |

Quality assurance

1.. Every production process has a special person to test to ensure quality

2. Have professional engineers to check the quality

3. All products have passed CE, FDA, ISO9001 and other certifications

4. Suntop Fiber Laser Marking Machine is subjected to strict ageing tests and continuous 24-hour laser beam output before leaving our factory to ensure 100% machine stability.

Packing List:

Wooden case, 1pcs/case

Laser protective glasses*1

Foot pedal *1

English manual *1

Hex wrench set *1

Metal business card

Power connection wire*1

CNC connection cable *1

USB*1

Laser inspection report