|

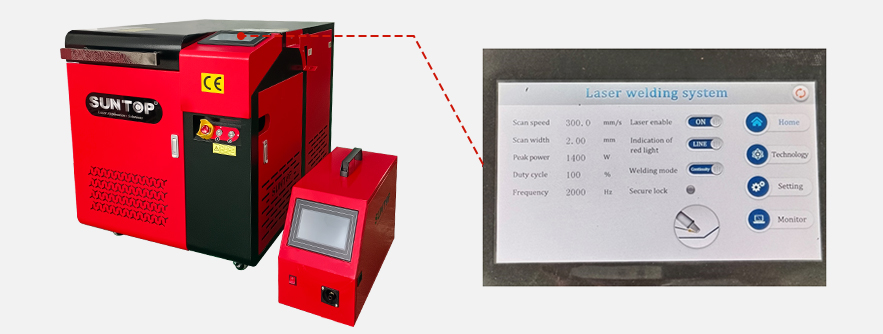

Laser sources

Features

- Customized 45um core diameter welding version fiber laser with a service life of 100,000 hours.

- No maintenance required, can weld all types of metals.

- It has the advantages of compactness, easy integration and high energy efficiency, and is suitable for high-precision, high-speed laser welding tasks.

|

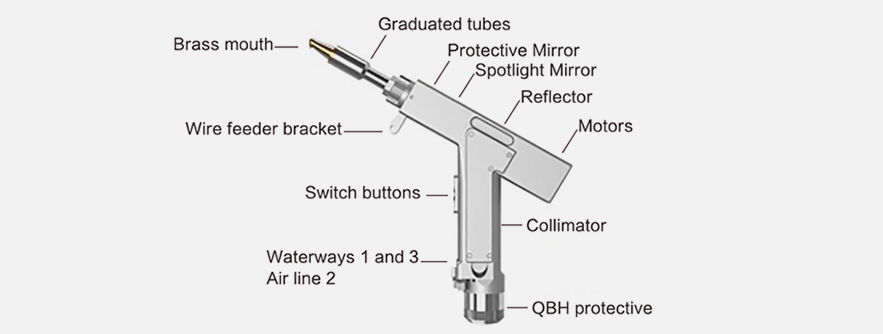

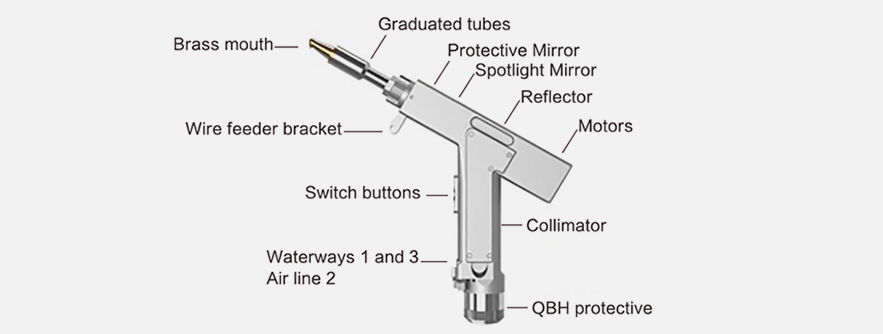

Self-developed Wobble Welding Head

Features:

- Self-developed control system and structural design, to adapt to a variety of welding needs within 3000W, set up a number of safety alarms and status indicators, the abnormal state of instantaneous response.

- Weighing only 0.7kg, it is compact and ergonomically designed, flexible operation, easy to use.

- Visualize all parameters and monitor the status of the entire machine in real-time to prevent issues, facilitate troubleshooting, ensure stable system operation.

- All process parameters can be set and various process effects can be tested flexibly.

|

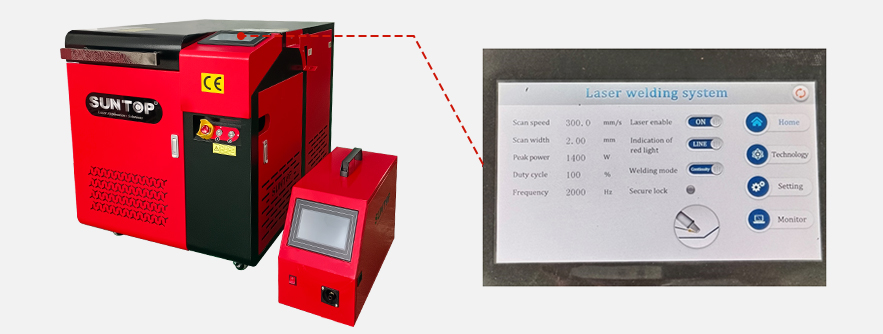

User-Friendly of Operation Interface

Features:

- Advanced resistive touch screen with higher sensitivity, intelligent control.

- Multi-language intelligent control panel, flexible adjustment of welding parameters, multi-group library of welding parameters and cumulative timing of light output etc.

- Support multiple languages (English, Spanish, German, Italian, French, Russian, Turkish, etc.)

|

Auto Welding Wire Feeder System (single/double feeder optional)

Features:

- Depending on the specific welding needs, the double wire feed can increase the width of the weld seam up to 8 mm, allowing for a high stacking effect on thicker sheet metal.

- Touch screen design, automatic wire filler, and fully digital design support stainless steel and aluminum wires with diameters of 0.8mm, 1.0mm, 1.2mm, 1.6mm, and 2.0mm.

- 220V power supply drive provides more powerful wire feeding, preventing wire jamming and resulting in more consistent welding quality.

|

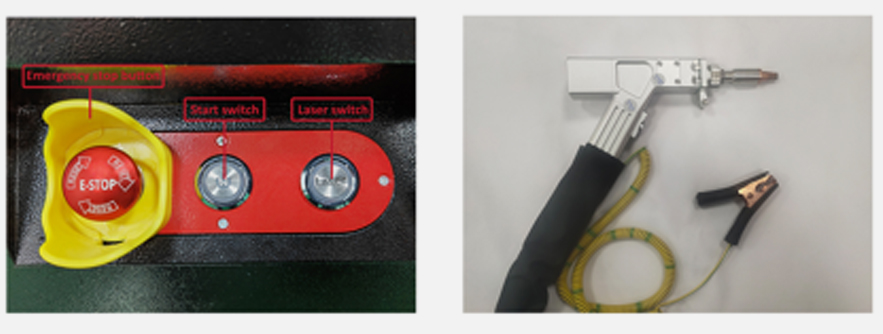

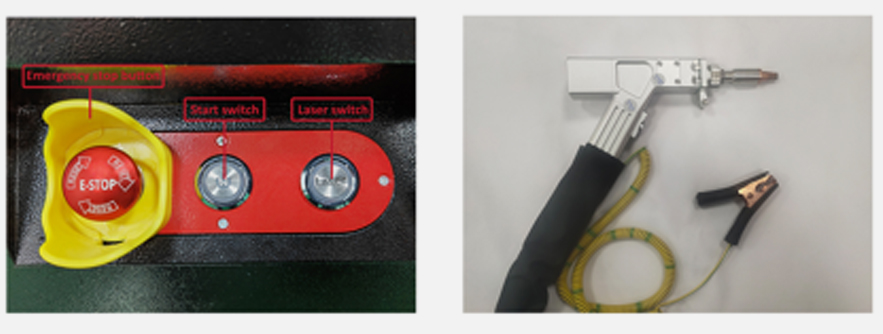

Operator Safety Features

Features:

ST-FW1500H/2000H/3000H is a Class IV laser system and routine precautions are required for the safe operation of the equipment.

Built-in features include:

- Key switch control of the laser source and an Emergency-stop button for deliberate operation.

- Fiber laser interlock to verify the integrity of laser delivery to the welding gun.

- Laser weld gun trigger for intentional operation.

- Part contact electrical interlock that turns off the laser power if the welding head is not in contact with the welded parts.

|

Cooling System

Features:

-Industrial chiller

Ensures heat dissipation of core optical path components, dual-circulation water cooling, better cooling of laser source and welding head.

-Cooling fan and temperature sensor

Add cooling fan and temperature sensor, when the temperature reaches the set temperature, the cooling fan will automatically turn on.