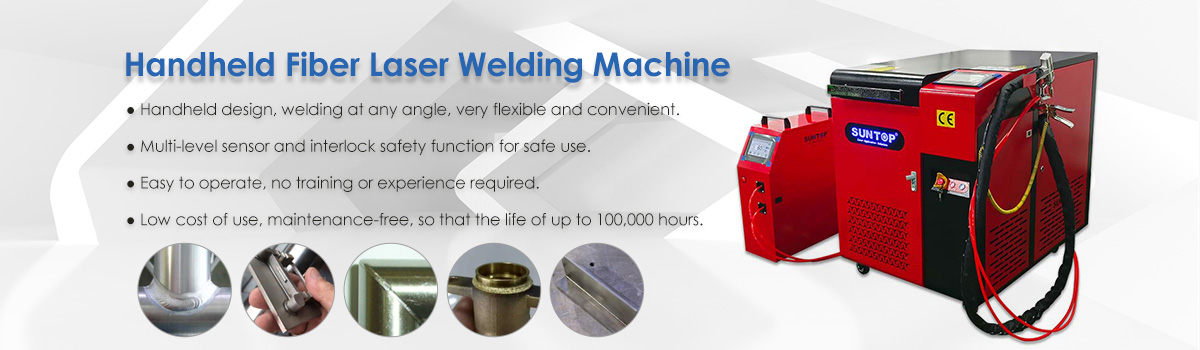

Details Product Parameters Samples Video

Features of laser welding copper

1. Infrared positioning is used to check and verify the position of the welding head during welding, resulting in more accurate welding positions and more beautiful weld seams.

2. The self-developed oscillating welding head compensates for the small laser spot's limitation, expanding the tolerance range of the workpiece and the width of the weld, resulting in a better welding effect.

3. The wire feeder utilizes a touch capacitive screen, ensuring high precision wire feeding. With a 220V drive, it provides more powerful wire feeding and prevents wire jamming.

4. It is equipped with a 10m imported optical fiber, overcoming the limitation of table space and allowing for flexible and convenient outdoor and long-distance welding.

5. It features a double protection function for the water circuit and air circuit (patented technology), effectively preventing damage to the laser lens or optical components caused by operator misoperation. This significantly reduces the machine's failure rate and prolongs its service life, as well as the life of the consumables.

6. Various standard welding copper nozzles, such as straight angle, inner angle, and outer angle, are included. Different nozzles can be replaced according to specific welding needs, ensuring versatility for various welding requirements.

Details of laser welding copper

1. Laser welding head

Light weight only 0.8KG, flexible and convenient to weld any shape of metal parts, adjustable welding seam width, can be 10 meters long distance welding. Equipped with safety temperature monitoring system.

2. Operation interface

Multi-language intelligent control panel, flexible adjustment of welding parameters, multi-group welding parameter library, light output cumulative timing, etc.

3. Automatic wire feeding system

Touch screen design, automatic wire filling, fully digital design, support 0.8mm, 1.0mm, 1.2mm, 1.6mm, 2.0mm diameter stainless steel and aluminum wire.

4. Laser Source

We use customized minimum 20um core diameter fiber for deeper penetration, laser life up to 100,000 hours, maintenance-free, with Bluetooth capability.

5. Water Chiller

Double cycle water cooling makes the laser source and welding head cooling better, temperature control sensor adopts imported brand.

6. Welding connection fiber optic

10 meters long fiber optic cable with built-in design effectively avoids damage to the fiber and problems caused by moisture, which greatly increases the service life of the laser components.

Advantages of laser welding copper

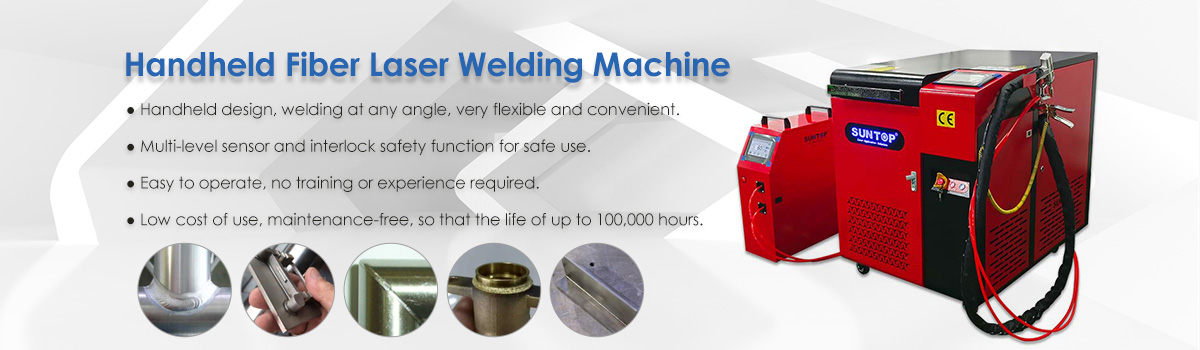

1. Flexible and convenient, the all-in-one design combines the laser, water tank, and control parts together, occupying a small area and requiring low site requirements. Equipped with movable casters, the workstations can be adjusted according to the site requirements, making it convenient and flexible.

2. Easy to operate and learn, no technical threshold required. Ordinary workers can operate it after a short training period, easily achieving high-quality welding results.

3. Small heat-affected zone, small yellow and black areas on both sides of the weld, and small overall deformation of the workpiece. The weld surface has a small height of deposition, eliminating the need for secondary grinding, reducing labor and time costs.

4. Multiple welding methods can be used to achieve welding at any angle, overlay welding, butt welding, vertical welding, fillet welding, inside corner welding, outside corner welding, etc. It can be used for welding various complex welds and large irregular-shaped workpieces.

5. Concentrated energy, small heat-affected zone, no deformation, no blackening, large weld depth, fine and beautiful weld appearance, strong and firm welding. The weld strength can reach or even exceed the strength of the base material itself.

6. Low usage and maintenance costs, with an electro-optical conversion efficiency of over 30% and a lifespan of over 100,000 hours. It requires minimal maintenance.

Use of laser welding copper

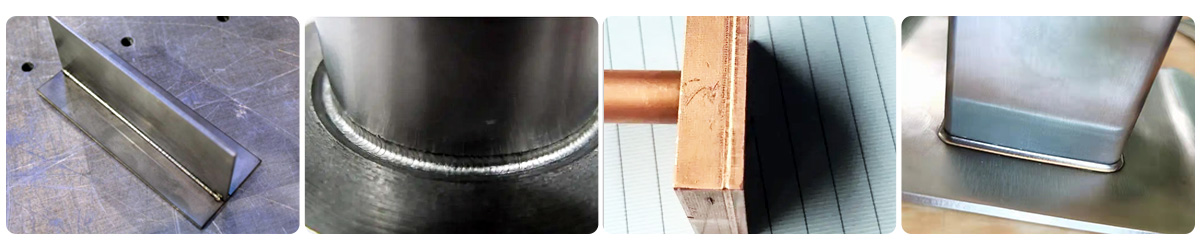

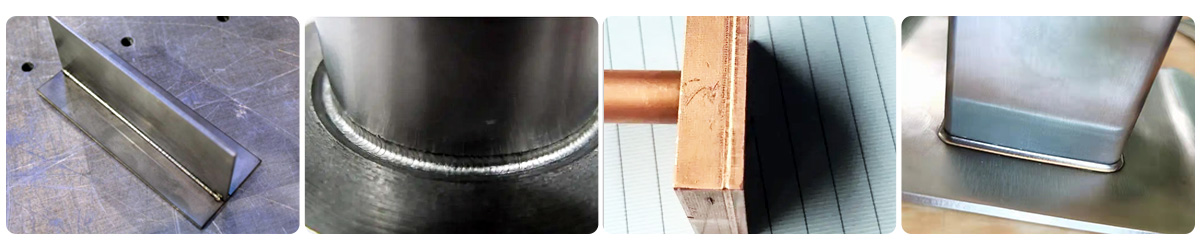

1. Welding

The main use of laser welding machine is undoubtedly welding. It can weld almost all metal materials and can complete welding well in various complex environments. It has high production efficiency and has more obvious advantages than traditional argon arc welding, electric welding and other processes. When welding, the production efficiency is high, which has more obvious advantages than traditional argon arc welding, electric welding and other processes.

Using a laser welding machine, the welding seam width is small, the depth is large, the thermal shock area is small, the deformation is small, the welding seam is smooth and beautiful, the welding quality is high, there are no pores, it can be precisely controlled, the welding quality is stable, and no processing or simple processing is required after welding.

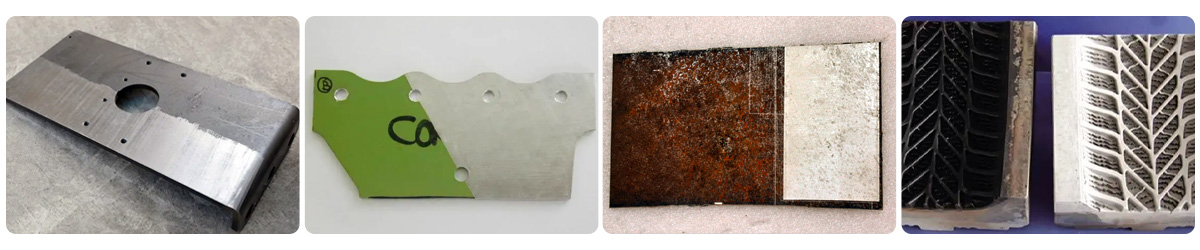

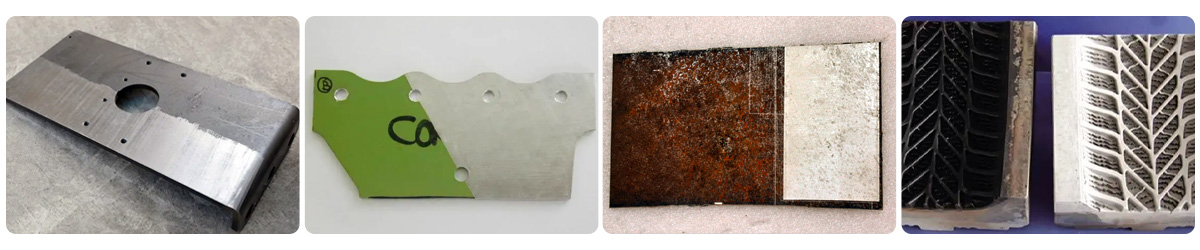

2. Cleaning

With the continuous reform and upgrading of laser welding machines, they have more and more functions. They can not only weld and cut, but also clean and remove rust. The laser welding machine uses the beam emitted by the laser to eliminate the pollution layer on the surface of the workpiece being processed. Cleaning using a laser welding machine is non-contact and does not require cleaning fluid. It can replace professional cleaning equipment.

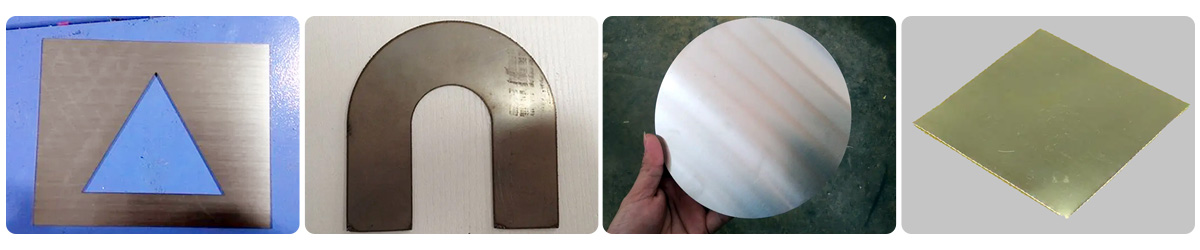

3. Cutting

Laser cutting is a new cutting method. The laser welding machine can be used to cut stainless steel, carbon steel, aluminum, aluminum alloy, iron and other metal sheets. The maximum cutting thickness is about 2mm.

4. Weld seam cleaning

In addition to the above three functions, our laser welding machine can also clean the weld seam. Laser cleaning can effectively remove oxides, welding slag, oil, dust and other impurities produced during the welding process, making the weld surface clean. This not only helps improve the quality of the weld, but also enhances its strength and appearance. Laser cleaning is highly precise and controllable, thoroughly cleaning the weld surface without damaging the base material.

Single side weld thickness

Maximum melting | 1500W | 2000W | 3000W |

Stainless steel (mm) | 0.5-4 | 0.5-5/6 | 0.5-6/7 |

Mild steel (mm) | 0.5-4 | 0.5-6 | 0.5-7/8 |

Aluminum (mm) | 0.5-3 | 0.5-4 | 0.5-5 |

Brass/copper (mm) | 0.5-2 | 0.5-2.5 | 0.5-3 |

Galvanized sheet (mm) | 0.5-4 | 0.5-5/6 | 0.5-6/7 |

Iron (mm) | 0.5-4 | 0.5-6 | 0.5-7/8 |

Remark: Double weld thickness can be achieved if the material is welded from both sides in two times.

Handheld laser welding and argon arc welding comparison

| TIG or MIG Welding | Fiber laser welding |

Heat effect to workpiece | Very high | Low |

Deformation of the workpiece | Big | Small or No |

Bonding strength to base metal | General | Very good |

After-treatment | Polishing | No need to rarely to polish |

Welding speed | General | 5-10 traditional welding |

Consumables | More | Less |

Operation difficulty | Complex | Simple |

Operational safety | Unsafe | Safe |

Environmental pollution | High | Less |

Welding fault tolerance | Good | Good |

Swing welding | No | Yes |

Spot width adjustable | No | Yes |

Welding quality comparison | Different | Very good |

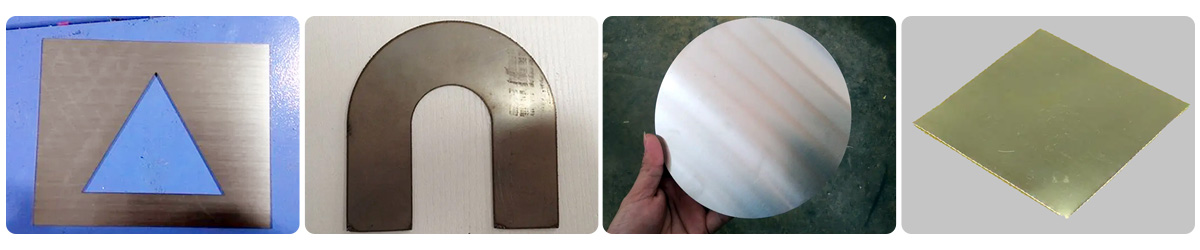

Application materials

It can be used for welding stainless steel, carbon steel, copper, aluminum, gold, chromium, silver, titanium, nickel and other metals or alloys. It can also be used for various welding between different materials, including copper – brass, titanium-molybdenum, titanium- gold, nickel-copper, etc.

Application industry

Widely used in sheet metal processing, chassis, water tanks, distribution boxes and other cabinets, door and window guardrails, advertising signs, battery components, steel furniture, electronic appliances, metal molds, auto parts, instruments, mobile communications, medical equipment and other industries.

Parameters of laser welding copper

Model | ST-FW1500H | ST-FW2000H | ST-FW300H |

Power | 1500W | 2000W | 3000W |

Welding gun weight | 0.8 | 0.8 | 0.75 |

Max. welding thickness (mm) | ≤3 | ≤5 | ≤8 |

Max. welding seam width (mm) | 5 | 5 | 8 |

Laser type | Fiber laser (Suntop custom 20um welding exclusive) |

Laser detection method | Bluetooth wireless connection, Mobile App Monitoring |

Control panel language support | English, Spanish, German, French, Turkish, Italian, Russian, Vietnamese, Thai, Korean, Japanese, etc. |

Laser wavelength (nm) | 1064+5 |

Suitable welding materials | Carbon steel, stainless steel, aluminum, galvanized sheet metal, brass, iron and other metal materials |

Adapted welding methods | Spot welding, overlap welding, splice welding, fillet welding, lap welding etc. |

Laser power adjustment range (%) | 10-100 |

Cooling method | Advanced water-cooling, dual temperature control and automatic control |

Welding aiming preview method | Built-in Red-Light pointer |

Protection systems | Air pressure sensor and solenoid valve control |

Length of fiber optic cable (meter) | Standard 10 (can be customized 15) |

Welding shielding gas | Argon or nitrogen (air pressure approx. 6-8 bar) |

Working environment | Temperature 5-45 °C /humidity 10-90% |

Other optional support functions | Cleaning + cutting | Cleaning + cutting | Cleaning + cutting + weld bead cleaning |

Max. Cutting thickness (mm) | 1.2 | 1.5 | 2 |

Max. cleaning width (mm) | 40 | 40 | 120 |

Automatic wire feeder type (Universal with TIG wire)

| Single wire feed | Single wire feed | Support both the double wire feed and single wire feed |

Solid wire type (SS, Iron, AL, Brass) | 0.8, 1.0, 1.2, 1.6 | 0.8, 1.0, 1.2, 1.6 | 0.8, 1.0, 1.2, 1.6, 2.0, 2.5 |

Temperature control monitoring alarm | Yes | Yes | Yes |

Main machine consumables | Laser protective lenes, welding nozzles, welding wires |

Machine size (MM) | 686*425*611 | 750*1080*1000 | 750*1080*1000 |

Machine net weight (KG) | 110 | 220 | 240 |

Power supply requirement | 110V / 220V±10%, single phase | 380V±10%, three phase |

Total power consumption (Maximum) | 3500W | 4500W | 7000W |