Details Product Parameters Samples Video

Features of laser rust cleaner machine

1. Integrated design, reasonable structure, dustproof, good heat dissipation, effectively extending the service life of machine parts.

2. The handheld cleaning head is small in size and light in weight, and can be operated manually or cooperated with a robot for automatic cleaning. It is especially suitable for cleaning special-shaped surfaces of large products that are difficult to move.

3. Intelligent control system with clear and concise interface and easy operation. Various parameters can be set to control the laser.

4. 10 meters of original optical cable and large universal casters, which can be moved left and right, making it easy to clean objects that are difficult to move.

5. Built-in cold water design avoids wire constraints, adapts to more working conditions and places, and has good dust-proof and anti-condensation effects.

6. It has multiple safety alarm functions and is highly safe, ensuring the absolute safety of operators when working.

Details of laser rust cleaner machine

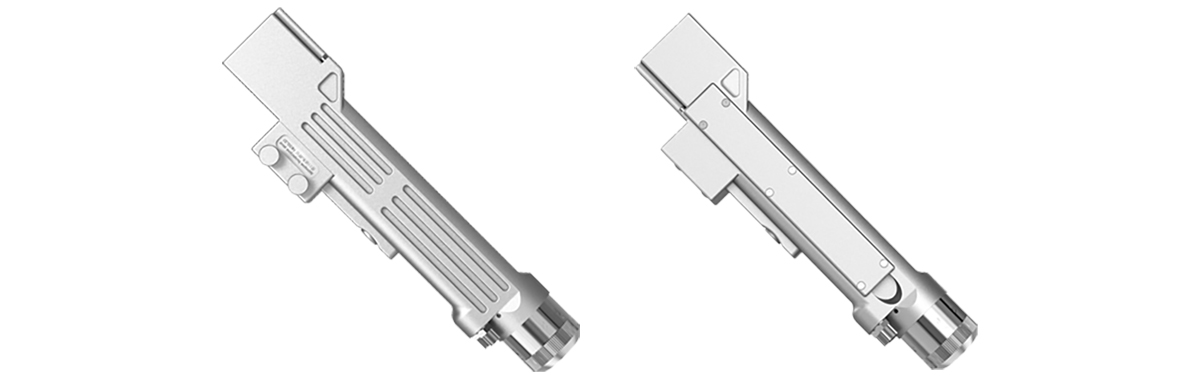

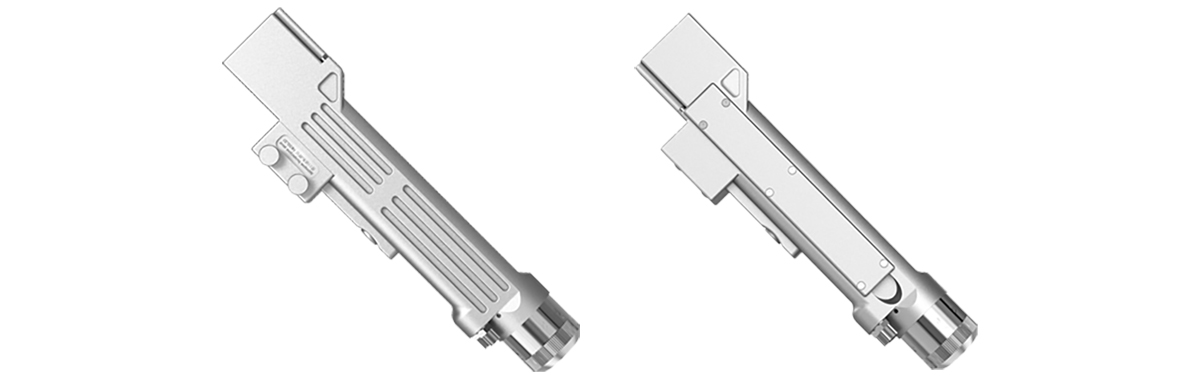

1. Laser cleaning head

Light weight only 0.7KG, flexible and convenient to clean metal parts of any shape, with a wide cleaning width, up to 300mm. Equipped with a safety monitoring system.

2. Operation interface

Advanced resistive touch screen with higher sensitivity, intelligent control, supports multiple languages (English, Spanish, German, Italian, French, Russian, Turkish, etc.)

3. Laser source

We use a customized 45um core diameter cleaning fiber laser with a lifespan of 100,000 hours and maintenance-free.

4. Water chiller

Double circulating water cooling makes the laser source and cleaning head cool better, and the temperature control sensor adopts imported brands.

5. Cleaning connection fiber

The cable distance from the laser cleaning head to the machine is 10 meters, and there is no need to move the machine when laser welding the workpiece.

6. Wide range of cleaning

The maximum cleaning area is 300*300mm, and the efficiency is high.

Advantages of laser rust cleaner machine

1. The "green" cleaning method does not require the use of any chemical agents or cleaning solutions. The waste produced from the cleaning process is mostly solid powder, which is small in volume, easy to store, and recyclable. This method can easily solve the environmental pollution caused by chemical cleaning.

2. Laser cleaning is a non-abrasive and non-contact cleaning method that does not damage the surface of objects.

3. Laser can be transmitted through optical fibers and can be combined with robotic arms and robots to easily achieve long-distance operations. It can clean areas that are difficult to reach with traditional methods, ensuring the safety of personnel in hazardous environments.

4. Laser cleaning can remove various types of pollutants on the surface of different materials, achieving a level of cleanliness that conventional cleaning methods cannot. It can also selectively clean contaminants on the surface of materials without damaging them.

5. Laser cleaning is fast, efficient, and time-saving.

6. Although the initial investment for purchasing a laser cleaning system is high, the system can be used stably for a long time with low operating costs, requiring only electricity fees per hour.

Cleaning ability (only for reference)

Power/W | Material | Cleaning speed | Effective beam/cleaning range | Depth of cleaning | Cleaning efficiency (cu.m./H) |

1500 | floating rust | 50mm/S | 150mm | 20um | 15 |

Paint | 50mm/S | 150mm | 100um | 6 |

Rusting | 50mm/S | 150mm | 120um | 4 |

2000 | floating rust | 50mm/S | 300mm | 20um | 20 |

Paint | 50mm/S | 300mm | 100um | 8 |

Rusting | 50mm/S | 300mm | 120um | 5 |

3000 | floating rust | 50mm/S | 300mm | 20um | 30 |

Paint | 50mm/S | 300mm | 100um | 14 |

Rusting | 50mm/S | 300mm | 120um | 9 |

Handheld cleaning head

● High cleaning efficiency, with a large welding width of up to 300mm.

● Precise positioning and cleaning, weighing only 0.7KG, making it easy to handle.

● Non-contact cleaning method that protects the material.

● Effectively removes particles as small as microns.

● Environmentally friendly, with no need for consumables.

Comparison between laser cleaning and traditional cleaning

1. Non-contact cleaning: Laser cleaning uses high-energy laser beams to irradiate the surface of the workpiece, causing dirt, rust spots or coatings on the surface to instantly evaporate or peel off without physical contact and avoid mechanical damage to the base material. Traditional cleaning methods require physical contact and may cause damage to the substrate.

2. High efficiency: Laser cleaning can complete the cleaning task in a short time and is highly efficient. Traditional cleaning methods are less efficient.

3. Precise control: Laser cleaning can control the depth, intensity and scope of cleaning by adjusting laser parameters to adapt to different cleaning needs. Traditional cleaning methods are difficult to achieve precise control.

4. No chemical solvents required: Laser cleaning does not require the use of chemical cleaning agents, reducing the impact on the environment and waste disposal costs. Traditional cleaning methods require the use of chemical cleaning agents.

Application materials

Suitable for removing resin, paint, oil stains, stains, dirt, rust, coatings, etc. from the surface of objects.

Application industry

Widely used in automobile manufacturing, mould, cultural relic restoration, aerospace, shipbuilding, 3C electronics, medical equipment, rail transit, steel manufacturing, military equipment, various steel, iron, aluminum materials and other industries.

Parameters of laser rust cleaner machine

Model | ST-FLC1500H | ST-FLC2000H | ST-FLC3000H |

Power | 1500W | 2000W | 3000W |

Laser wavelength | 1064nm |

Operation mode | Handheld |

Power adjustment range (%) | 10-100 (Gradient adjustable) |

Cleaning head weight | 0.7Kg |

Delivery cable length | 10M (can be customized) |

Cooling system | Water Cooled with automatic pumping function |

Input power | 220V±10% 50-60HZ | 380V±10% 50-60HZ |

Power consumption | 4500W | 6000W | 8000W |

Max. cleaning width | 200*200mm | 250*250mm | 300*300mm |

Machine weight | 120KG | 200KG | 220KG |

Machine size | 935*720*1248mm | 1500*880*1160mm |