Laser protective lens description

The laser lens occupies a very important position in the laser system, and the change of the laser light path is realized by the refraction of the lens.

Laser protective lenses, also known as laser windows, are mainly used in laser cutting machines, laser cleaning machines, laser welding machines, laser marking machines and other laser equipment to block or prevent high-temperature splashes, protect focusing lenses, electronic sensors, Optical lenses for semiconductor components. At the same time, the lens cannot weaken the laser output energy. Mechanical properties such as light transmittance, surface accuracy, thickness, parallelism, and base material are important parameters for laser protection lenses.

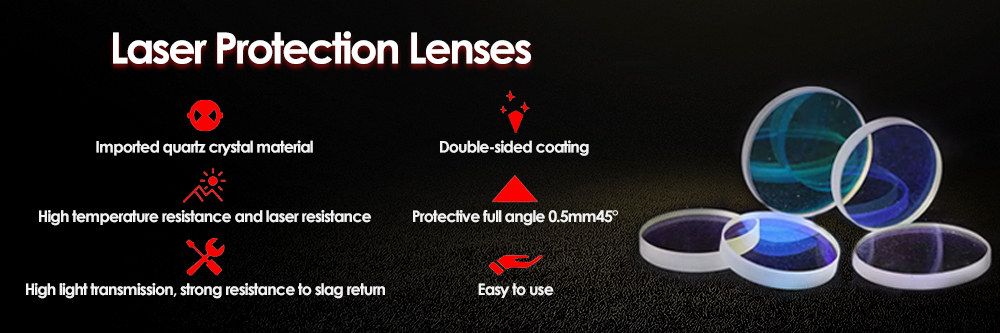

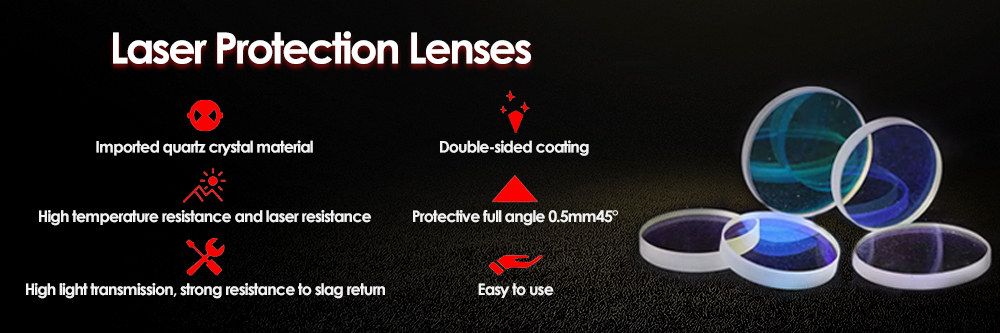

Laser protective lens features

● No chipping, not easy to crack

Imported quartz crystal material, uniform texture, high mechanical strength, high temperature resistance, high pressure, the lens is not easy to chip and crack.

● High temperature resistance, strong anti-laser performance

It is made of high-quality substrates with excellent optical performance and good thermal stability, and is finely processed through cutting, polishing, grinding and other high-precision processes. The lens is resistant to high temperature and has strong anti-laser performance.

● High light transmittance, strong anti-slag resistance

Both sides of the lens are coated with an anti-reflection coating with a high damage threshold to reduce loss due to reflection, and the coating protects it from splashes and other hazards for long life.

● Safe and easy to use without hurting hands

Humanized 45° protective full-angle design, easy to apply and not hurt your hands.

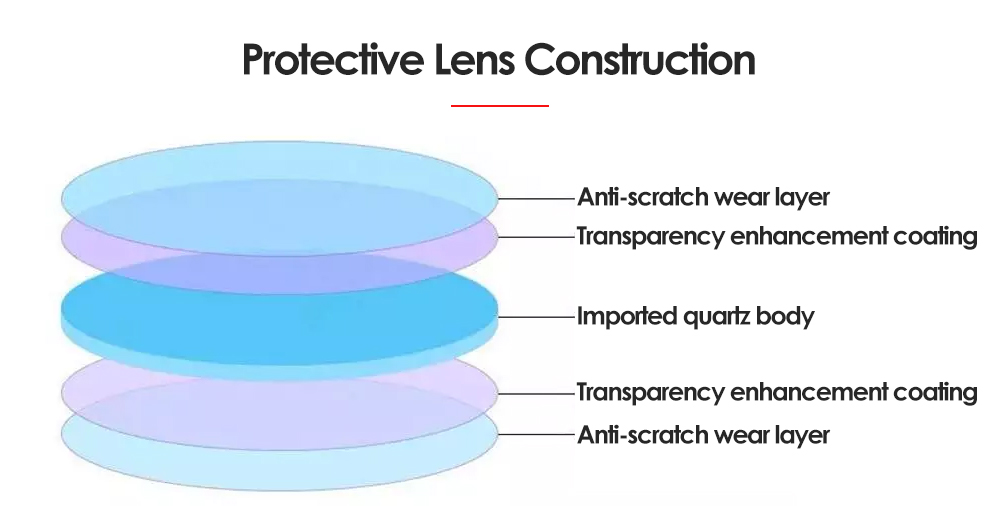

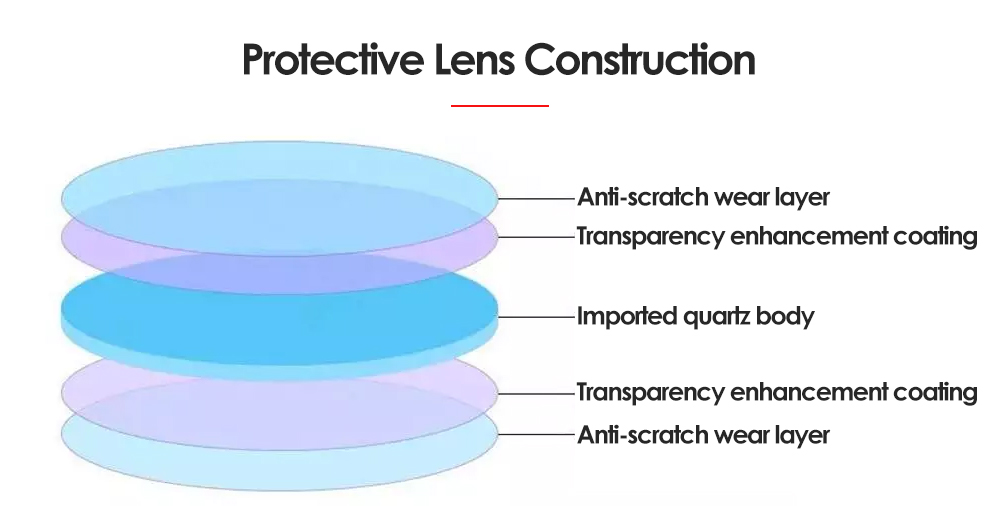

Laser protective lens structure

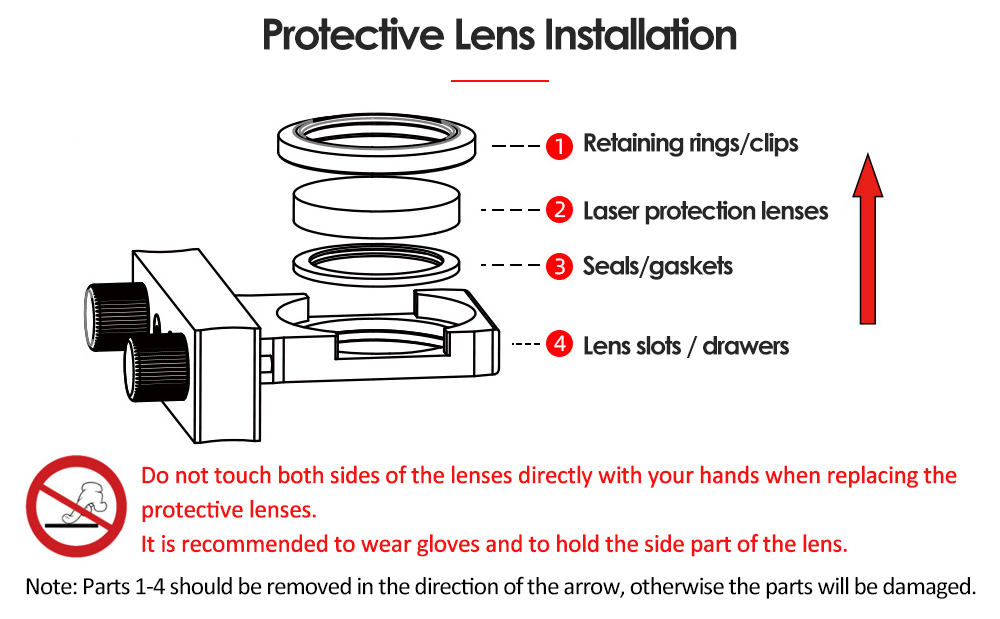

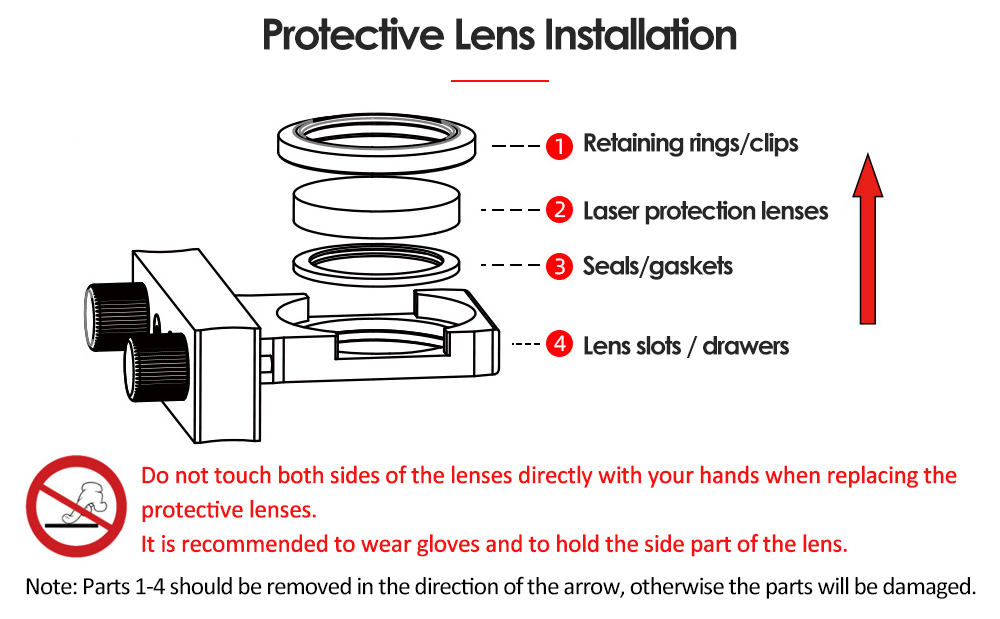

Laser protective lens installation

1. Remove the protective lens

● Slightly remove ① the fixing ring, and then remove ② the protective lens.

● Put the ② protective lens cover into a clean container, and the mirror surface cannot be in contact with non-gas substances.

2. Clean and protect the lens

● Dip the isopropanol solvent with a dust-free cleaning stick to clean the protective lens, and then blow off attached particles and other foreign objects with clean air;

● Repeat several times until the lens is clean;

● If the protective lens cannot be cleaned or is damaged, it must be replaced with a new one.

3. Check the sealing ring

● Check whether the sealing ring is deformed or notched, which may cause air leakage.

The sealing ring cannot be dropped to the ground and other environments with dirt, dust and roughness.

4. Install the protective lens

● Put the cleaned ② protective lens into the lens slot carefully.

● Put in the fixed ring ①, pay attention to check whether the sealing ring ③ is under the protective lens.

Laser protective lens application range

Laser cutting machine, laser marking machine, laser welding machine, laser cleaning machine, etc.