Details Product Parameters Samples Video

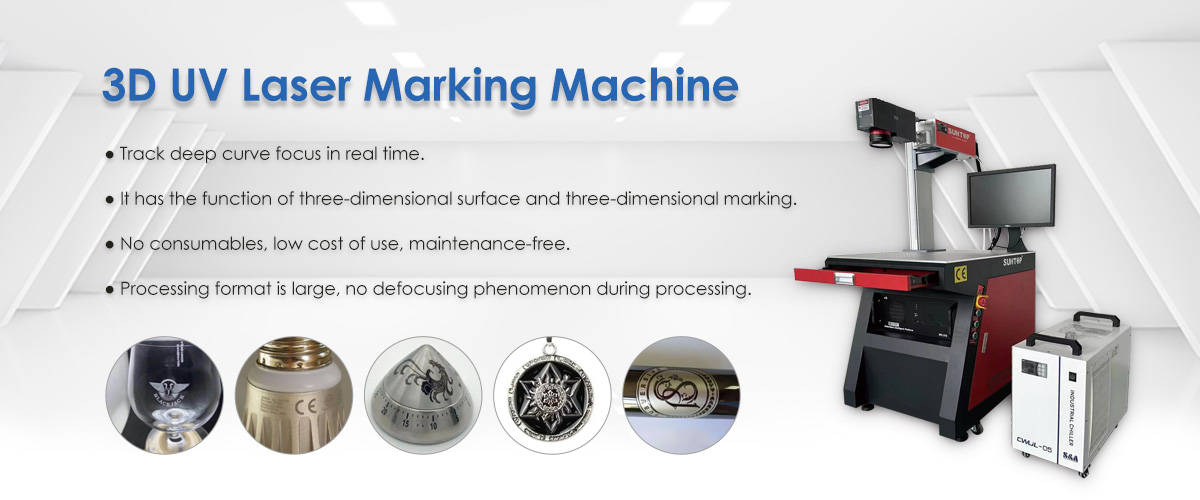

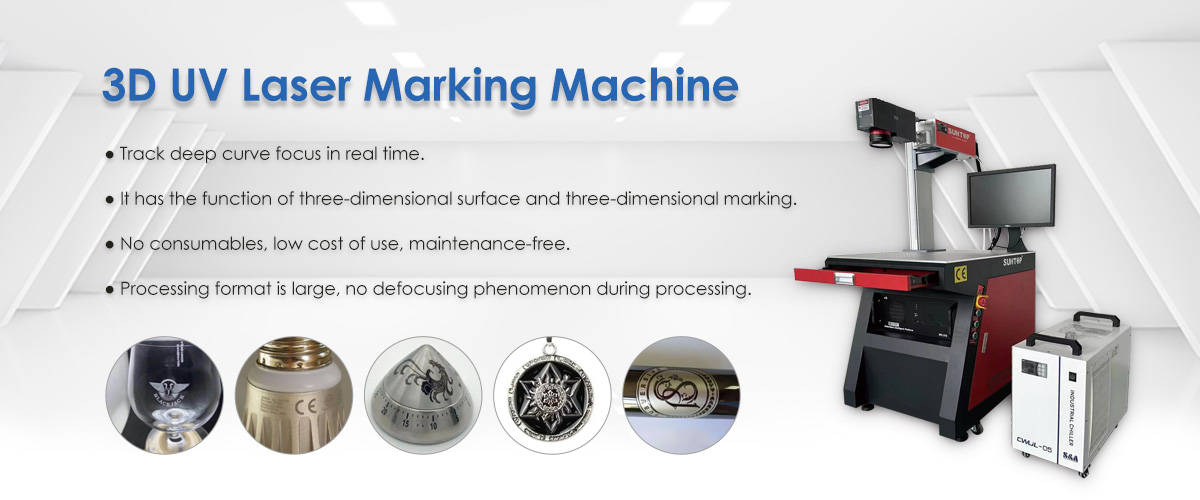

Features of laser marking technologies llc

● Good beam quality and smaller focal spot for ultra-fine marking.

● Subvert the traditional two-dimensional marking mode, to achieve all-round marking, can be engraved bevel, cylinder, cone, sphere and other different 3D shapes.

● Automatically calculates radian and automatically adjusts focus for marking multi-level large format, 3D curved surfaces and more.

● Adopt multi-axis dynamic zoom technology to track deep curve focus in real time.

● Adopting 3D fine marking system software, it can meet various manual engraving needs, such as relief patterns, deep engraving, shade engraving, etc., which improves the three-dimensional sense of details.

● Large processing width, marking range can be adjusted according to the specific processing requirements, and there is no defocus phenomenon during the whole process.

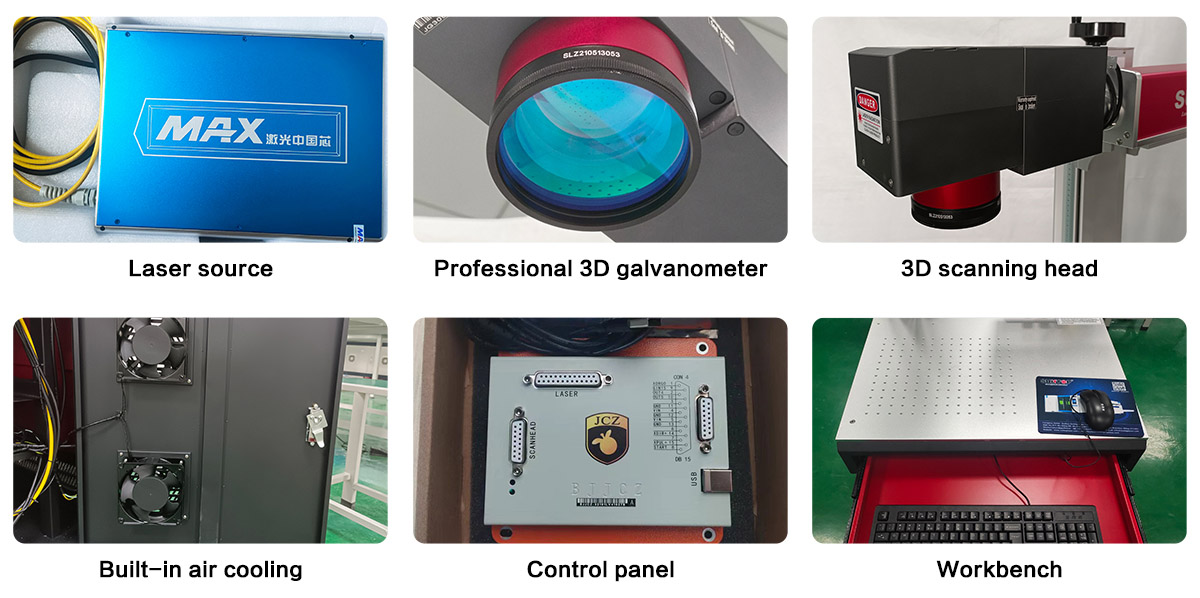

Details of laser marking technologies llc

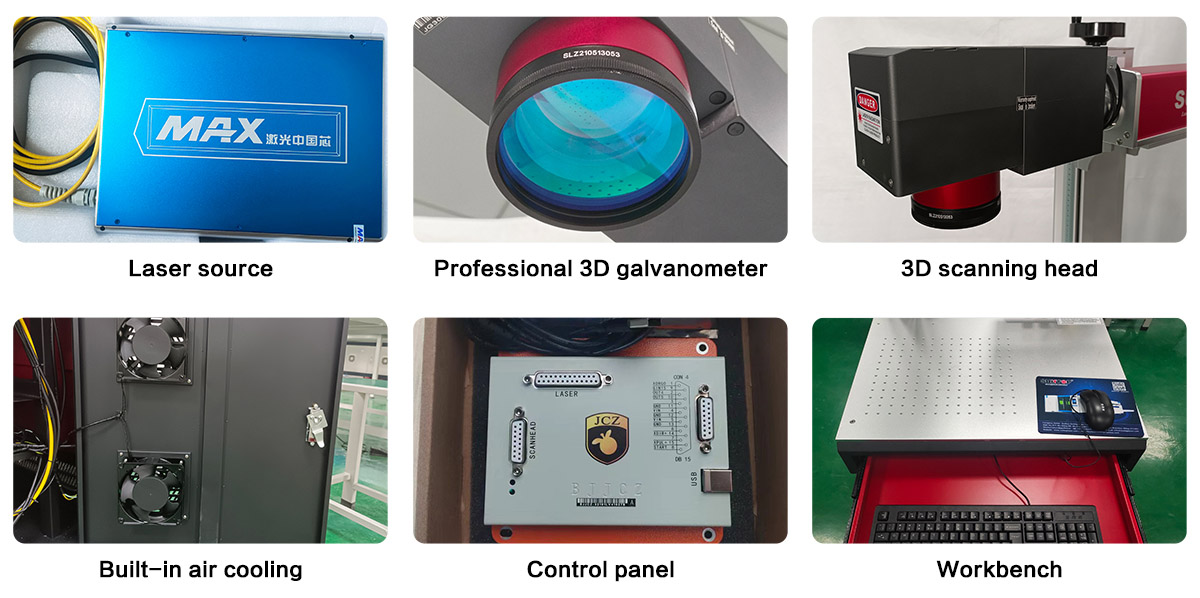

1. Laser source

Adopt high quality UV light source, high beam quality, good stability, high efficiency and long life.

2. 3D digital scanning head

Famous brand SINO-GALVO oscilloscope scanning head, high speed and accurate marking.

XYZ three axes, irregular / surface marking, Z axis can be flexible automatic movement.

3. Professional 3D galvanometer

Variable focal length, precise control of focal position, ensure focal size and spot quality to realize the engraving of irregular products.

4. Water cooling system

Water cooling system is adopted to accelerate heat dissipation. Protect the host computer to ensure the machine runs for a long time.

Advantages of laser marking technologies llc

● Three-dimensional marking technology: Using advanced three-dimensional marking technology, it can adaptively adjust according to the three-dimensional shape and surface of the target object to achieve high-precision marking of curved surfaces.

● Applicable to a variety of curved surfaces: It is suitable for various irregular-shaped objects, such as auto parts, handicrafts, packaging bottles, etc., and can achieve 360-degree all-round marking.

● High-precision marking: With high energy density and fine imaging capabilities, it can achieve micron-level marking of curved surfaces and keep the marking pattern clear and fine.

● Autofocus: Equipped with autofocus function, it can dynamically adjust according to the unevenness of the object surface to ensure mark quality and consistency.

● Mass production: It is suitable for batch production environment, has the characteristics of high efficiency and high output, and is suitable for automated production equipment on the production line.

●Easy to operate: Usually equipped with user-friendly operating software and interface, easy to operate and adjust parameters, improving work efficiency.

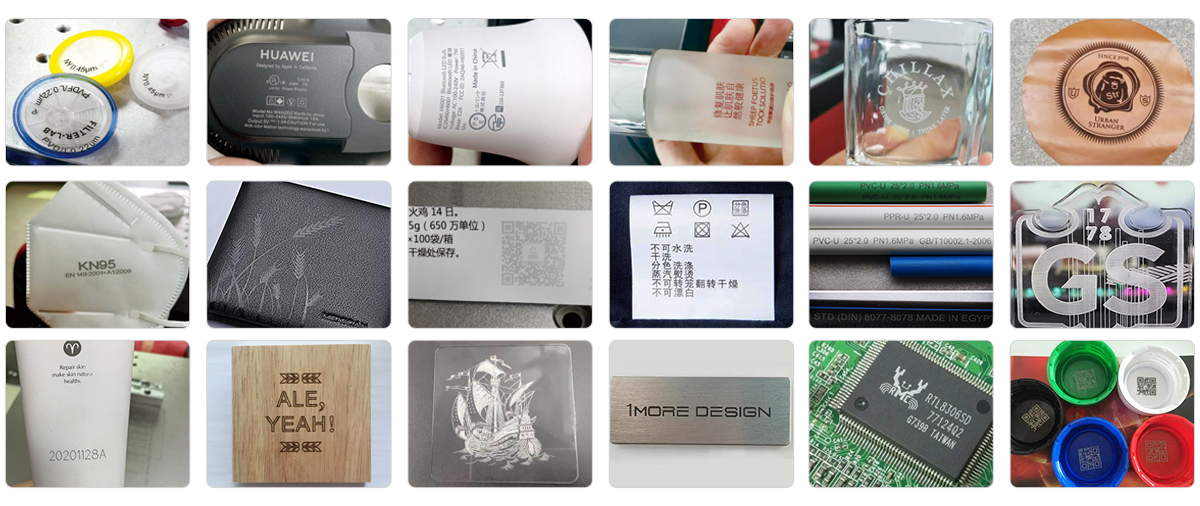

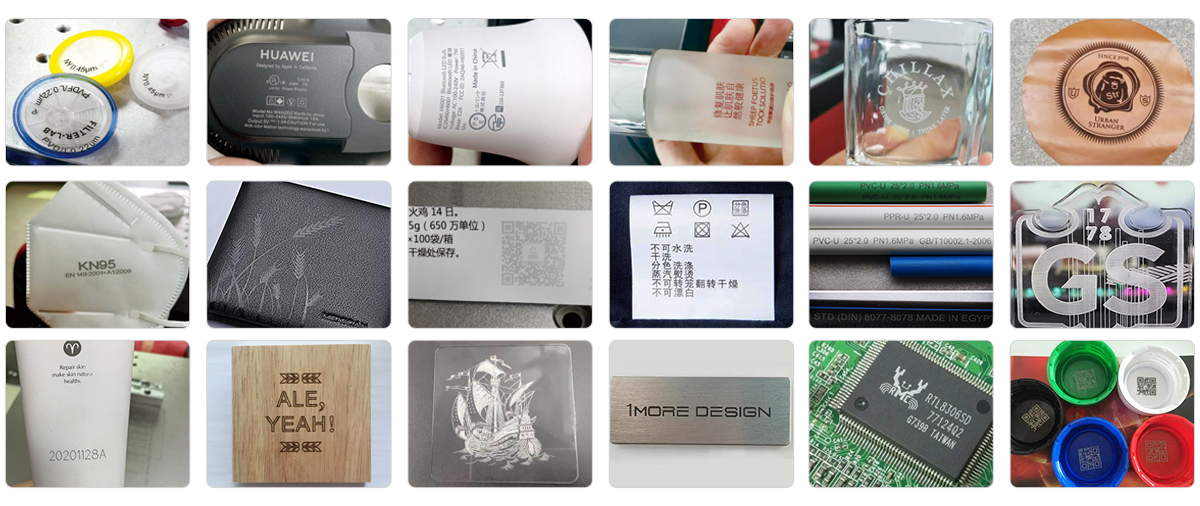

Application materials of laser marking technologies llc

It is suitable for almost all materials. Widely used in metal (all metals such as iron, copper, aluminum, magnesium, zinc, etc.), glass, crystal, PCB, plastic, fiber, paper, paint, silicon wafer, LCD, polyamide, wire, plug and other polymer materials.

Application industry of laser marking technologies llc

Especially suitable for the high-end market of ultra-fine processing, skin care cosmetics, medical drugs, food, silicon wafer micro-hole, blind hole processing, glass products, metal products, plastic buttons, electronic components, gifts, communication equipment, building materials, etc.

Parameters of laser marking technologies llc

Model | ST-UV03/05/10/15/20-3D |

Laser Power | 3W/5W/10W/15W/20W |

Max. marking range | 110*110mm-180*180mm |

Laser Type | UV laser |

Laser source | GAIN (JPT and other brand optional) |

Control Software | EZCAD |

Cooling Mode | Water Cooling |

Beam diameter | ≤ 10mm |

Working Accuracy | ±0.002MM |

Marking Speed | 1-12000mm/s |

Repetition Frequency | 20-100KHz |

Laser Wavelength | 355nm |

Minimum Font for Marking | 0.01mm |

Working Voltage | 220V+10% 50/60 Hz |

Graphic Format Supported | AI, PLT, DXF, BMP, DST, DWG, DXP |

Spare Parts Come with the Machine | Protective glasses, Metal business card, Foot switch, Hex socket wrench, Power cord |

Optional Accessories to Purchase | D80 Rotating Shaft/ D57 Small Chuck/2D Table (X.Y direction)/ Cutting Fixture |

Net Weight (KG)/ Gross Weight | 170KG / 195KG |

Packaging Dimension | 880mm*780mm*1750mm (L*W*H) |