Details Product Parameters Samples Video

Features of laser marking services

1. Adopting CCD camera positioning system, accurate positioning, marking products can be placed randomly, and multiple products can be placed at one time, and products can be automatically recognized by the software at any position, any angle and any shape, so as to complete the automatic marking of multiple products at one time.

2. Fast auto-focusing, automatic marking, no need for manual adjustment.

3. Can be used with the production line, reduce labor costs, can work continuously for 24 hours, can meet the requirements of industrialized large-scale online production.

4. The software has a high precision correction function to ensure the accuracy of visual positioning. The software is easy to operate and quick to use.

5. Intelligent vision positioning system automatically batch processing, capacity increase 3~10 times.

6. No consumables, high precision, fast processing speed, power saving and energy saving, saving time, energy and cost.

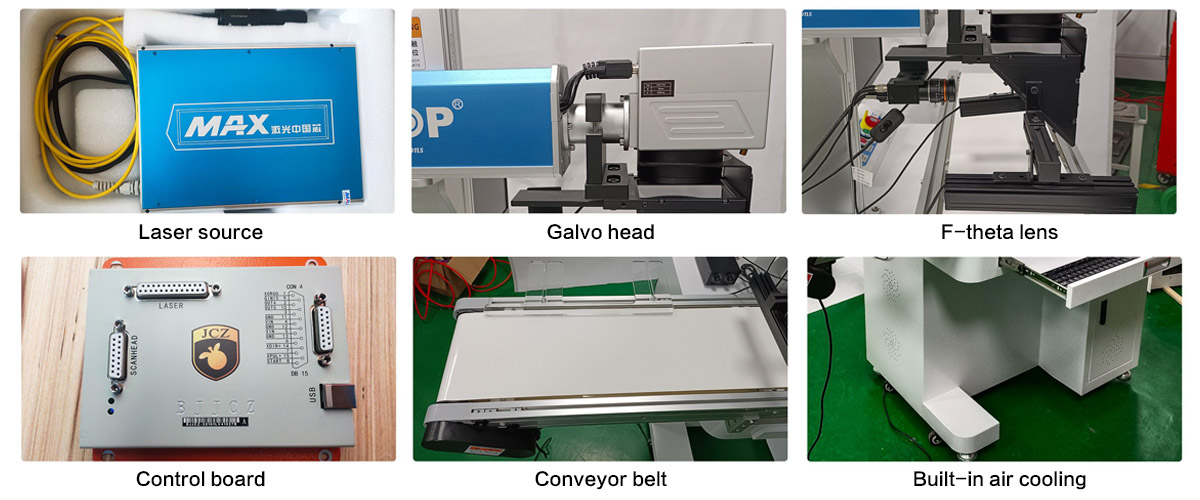

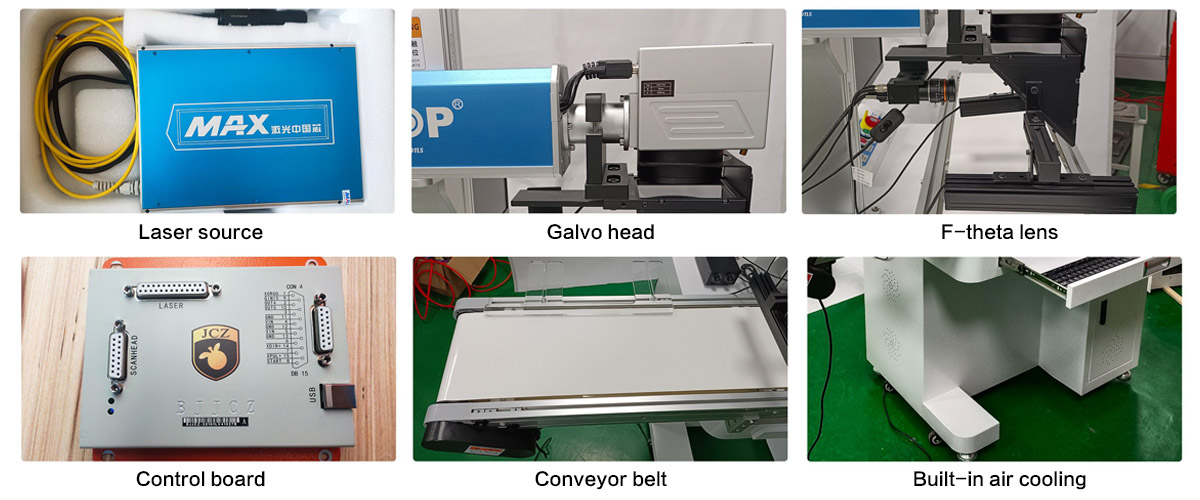

Details of laser marking services

1. Laser source

Using well-known brands of fiber lasers such as Raycus, MAX, and IPG, the performance is stable and the photoelectric conversion efficiency is high. There is no need to maintain the laser and beam transmission system, which can save a lot of maintenance costs and time.

2. High-speed galvanometer

High-precision laser scanning vibrating head, fast and clear, high stability.

3. High Lens

The use of quartz high-transparency coating field lens greatly improves the light-gathering ability of the edge beam, high light transmittance, and good marking effect.

4. Control panel

Original JCZ EZCAD software and control card, USB interface, swift and stable transmission.

Advantages of laser marking services

● High-precision positioning: CCD cameras can achieve high-precision product positioning and identification, ensuring that laser marking is performed at the correct position and improving processing accuracy.

● Automatic identification: CCD vision system can automatically identify features, patterns or barcodes on products, reducing manual intervention and improving production efficiency.

● Versatility: In addition to laser marking function, CCD vision system can also be equipped with other functions, such as quality inspection, image recognition, etc., providing more application options.

● Wide applicability: The CCD vision laser marking system can be used for marking products of various shapes, sizes and materials, and has strong versatility and adaptability.

● High efficiency: The combination of automated CCD vision system and laser marking technology can improve production efficiency and reduce labor costs and time costs.

● High-quality output: The CCD vision system ensures the position accuracy and marking quality of laser marking, ensuring that the output products have high-quality logos and patterns.

● Fine processing: CCD visual laser marking technology can realize fine processing of patterns, text, images, etc. on products to ensure the clarity and accuracy of markings.

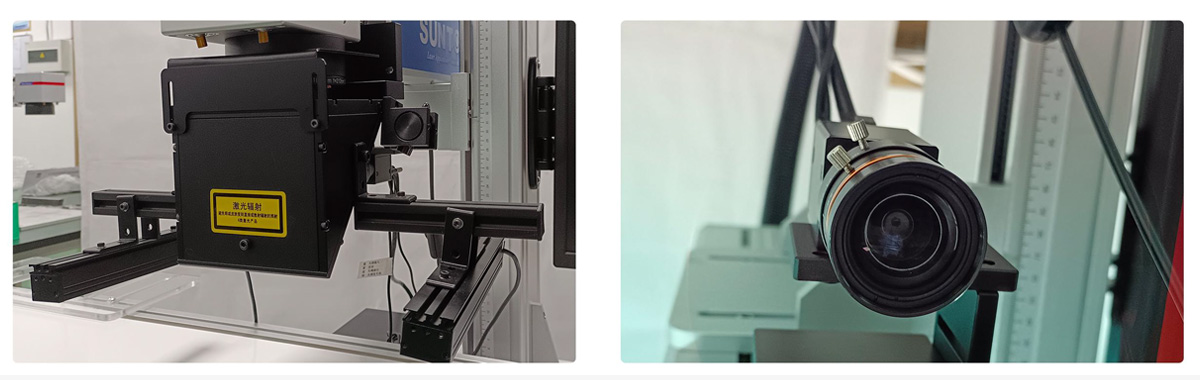

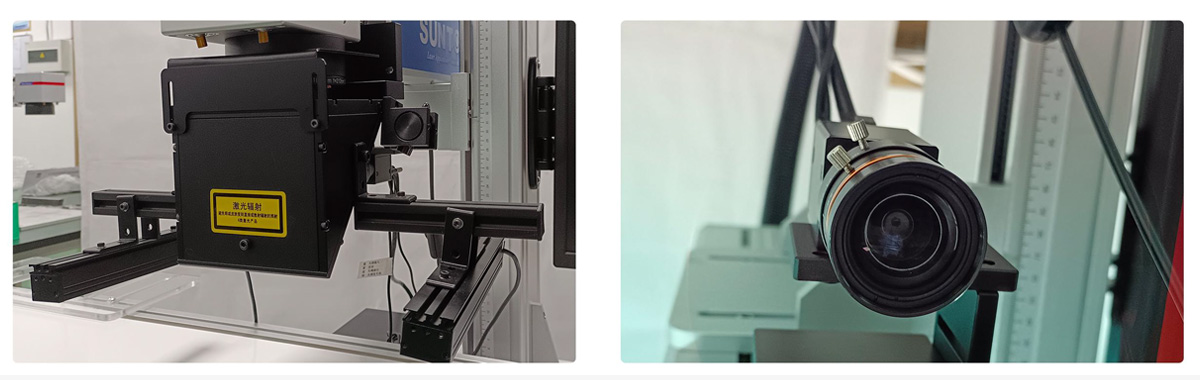

CCD visual system

1. The automatic laser marker with CCD visual positioning is mainly for batch and irregular products.

2. lt can achieve high precision positioning and marking at any angle, number and position of materials.

3. Visual positioning solves the problems of difficult feeding, inaccurate positioning and slow speed caused by the difficulties in fixture design and manufacture.

4. lt can be solved by taking real-time pictures with an external camera and capturing the feature points.

5. With the cooperation of vibration disc, assembly line, XY platform and other components, unmanned and automated production can be achieved, greatly improving product quality and production efficiency.

Application materials of laser marking services

Suitable for working with most metal marking applications such as Gold, Silver, Stainless Steel, Brass, Aluminum, Steel, Iron Titanium etc., and can also mark on many nonmetal materials, such as ABS, Nylon, PES, PVC etc.

Application industry of laser marking services

KBC Industrial, cooking utensils, tools, lC, auto parts, Lamp bubble parts, LED plastic parts, Machine parts, Target automobiles sectors, knives, cylinder metal parts, Jewelry, luggage buckle, electronic industry, lC industrial, hardware industry, sanitary ware industry, food packing industrial, etc.

Parameters of laser marking services

Model | ST-VFL20W/30W/50W/70W/100W |

Laser power | 20W/30W/50W/70W/100W (optional) |

Marking area | 110*110/175*175/200*200/300*300mm (depend on the actual laser power) |

CCD visual range | 120*120mm |

Laser wavelength | 1064nm |

Working accuracy | ±0.002mm |

Marking Depth | 0-0.5mm |

Minimum font for marking | 0.15mm |

Minimum character | 0.2mm |

Marking speed | 0-7000mm/s |

Operating system | Win7 and Win10/32 bit and 64 bit |

Laser source | MAX Brand(Raycus can be choose) |

Repetition frequency | 20-100KHz |

Cooling mode | Air Cooling |

Graphic format supported | AI, PLT, DXF, BMP, DST, DWG, DXP |

Environmental requirements | Temperature: 10-35℃, Humidity: 5-75% |

Working voltage | 220V±10% 50/60 Hz |

Applicable material | All metal (Stainless steel, Carbon steel, Brass,etc.) and some plastic(ABS, PVC,PES, ETC.) |

Optional Accessories to Purchase | D80 Rotating Shaft/ D57 Small Chuck/2D Table (X.Y direction)/ Cutting Fixture |

Net weight/gross weight (KG) | 140KG / 168KG |

Machine dimension | 800*600*1400mm (L*W*H) |