Details Product Parameters Samples Video

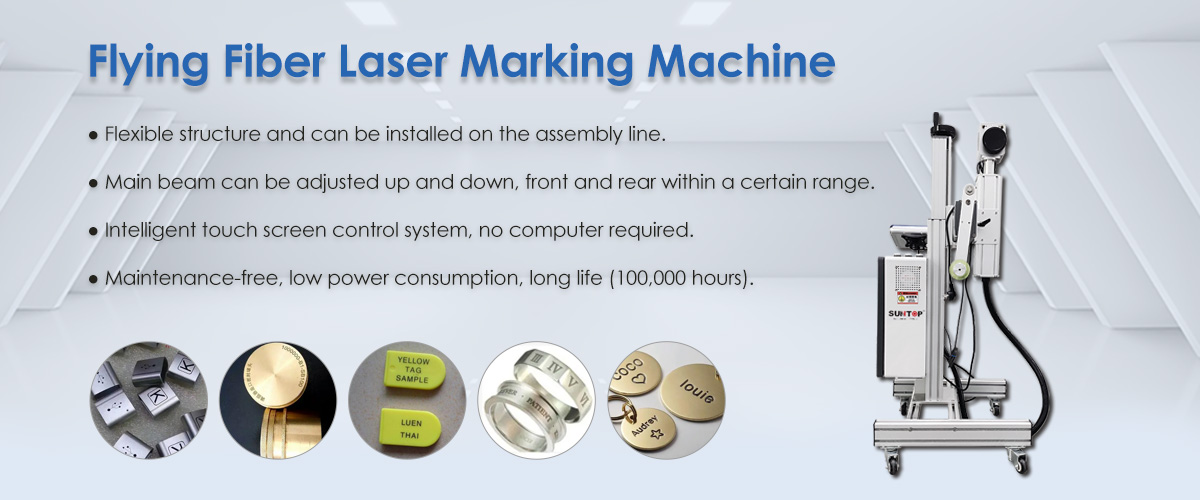

Features of laser marking products llc

● Flexible structure, small footprint, professional support can be installed on the assembly line, easy to adjust.

● Built-in air cooling, no maintenance required. Intelligent touch screen control system, no computer required, easy to use.

● The camera is compatible with a variety of focusing lenses, and can adjust a variety of light output directions to meet theneeds of different application scenarios.

● Stable and ight main beam lifting mechanism can adjust the main beam up and down, front and back within a certain range.

● It has the characteristics of short start-up time, narrow light pulse, high peak power, wide repetition frequency range, and no shadow and dotted line phenomenon in special material processing, which can meet the marking needs of most users.

● Designed for high-speed production lines, it can be flexibly installed and used in conjunction with production lines. The frame can be adjusted by moving up and down, left and right, and the marking head can be selected for marking at 360°.

Details of laser marking products llc

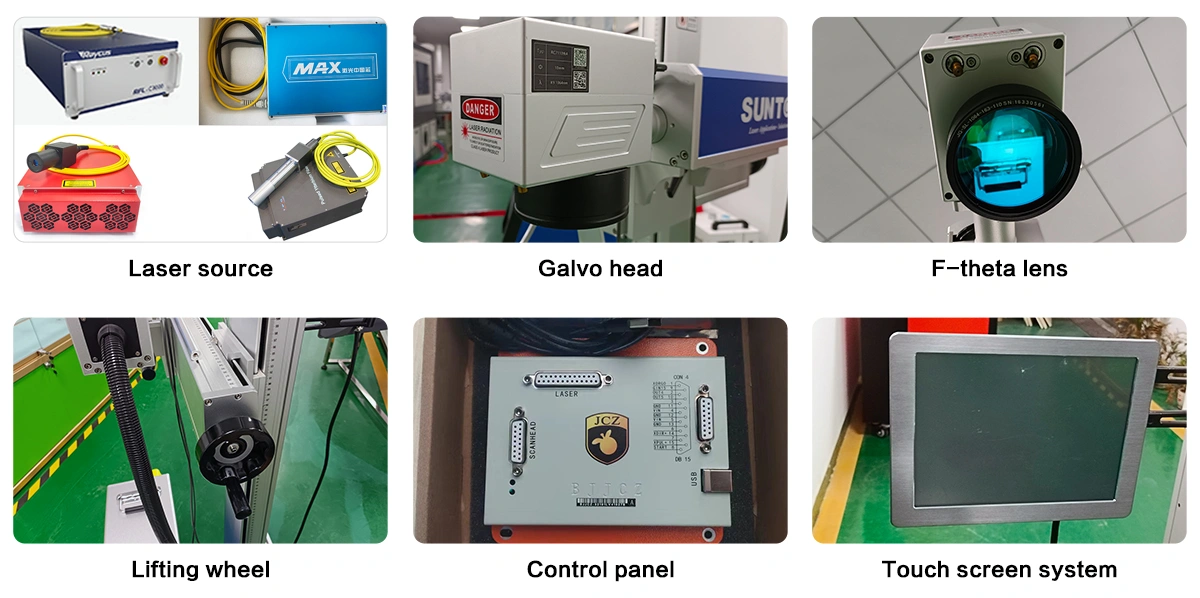

1. Brand laser

Using famous brand MAX, Raycus, JPT lasers, the light output is stable, the light spot is delicate, and the focusing effect is strong.

2. High-speed galvanometer

Sino-Galvo scanner head has good operation stability, high positioning accuracy, fast marking speed and strong anti-interference ability.

3. High Field lens

The use of quartz high-transparency coating field lens greatly improves the light-gathering ability of the edge beam, high light transmittance, and good marking effect.

4. Touch screen industrial computer

Touch screen experience, running without stuttering, and has high anti-magnetic, dust-proof, impact-proof and strong anti-interference ability, and can work continuously for a long time.

5. Flying marking system

Based on the development of marking on the fly, it is very easy to edit any file pattern, etc., it can automatically produce batch numbers and serial numbers, and the software parameters can be modified flexibly.

Advantages of laser marking products llc

● High precision and high quality: Laser marking technology can achieve very high-precision marking and engraving, and can produce clear and fine marks on the surface of various materials, including text, patterns, QR codes, etc. This high-quality marking enhances the appearance and value of your product.

● High efficiency and productivity: Laser marking is fast, easy to operate, and has a high degree of automation in the marking process. It can quickly complete the marking task of a large number of products. Compared with traditional marking methods, laser marking can significantly improve production efficiency.

● Non-contact processing: Non-contact processing technology, the laser beam directly acts on the surface of the workpiece, will not cause mechanical vibration or scratches, avoids surface wear and damage, and is suitable for applications with high requirements on product surfaces.

● Flexibility and customization: Laser marking can achieve diversified marking content and styles, and various marking effects can be customized according to customer needs, including text, patterns, barcodes, serial numbers, etc., to meet the needs of different industries and applications.

● Permanence and durability: The marks formed by laser marking are permanent and durable and are not easy to wear, fade or be washed away. They can remain clearly visible for a long time and are suitable for products or equipment that require long-term marking.

● Environmental protection and energy saving: Laser marking is a green and environmentally friendly processing technology that does not produce waste gas, waste water, waste residue and other pollutants, and is energy-saving and environmentally friendly. At the same time, there is no need to use chemical dyes or solvents, which complies with modern environmental protection standards.

Application materials of laser marking products llc

Suitable for working with most metal marking applications such as Gold, Silver, Stainless Steel, Brass, Aluminium, Steel, Iron Titanium etc, and can also mark on many nonmetal materials,such as ABS, Nylon, PES, PVC etc.

Application industry of laser marking products llc

Widely used in electronic components, integrated circuits (ICs), electrical appliances, mobile phone communications, hardware products, tool accessories, precision instruments, glasses and watches, jewelry, auto parts, plastic keys, building materials and PVC pipes.

Parameters of laser marking products llc

Model | ST-FL20F/ST-FL30F/ST-FL50F/ ST-FL70F/ST-FL100F |

Laser power | 20W/30W/50W/70W/100W |

Max. marking range | 110*110mm/150*150mm/200*200m/300*300mm |

Whole machine power | 600W/h |

Laser wavelength | 1064nm |

Laser source | MAX Brand ( Raycus can be choosed) |

Control software | EZCAD |

Cooling mode | Air Cooling |

Working accuracy | ±0.002mm |

Marking speed | 0-7000mm/s |

Repetition frequency | 20-100KHz |

Minimum font for marking | 0.15mm |

Graphic format supported | AI, PLT, DXF, BMP, DST, DWG, DXP |

Working voltage | 220V±10% 50/60 Hz |

Applicable material | All metal (Stainless steel, Carbon steel, Brass,etc.) and some plastic(ABS, PVC,PES, ETC.) |

Net weight/gross weight (KG) | 75KG / 100KG |

Machine dimension | 450*750*1400mm (L*W*H) |