Choosing the right laser engraver for you requires several considerations to ensure that the selected equipment can meet your specific needs.

1. Application requirements

Material type: Determine the material you will be engraving or cutting (such as metal, wood, plastic, glass, etc.). Different types of laser engravers are designed to handle different materials. Make sure the machine you choose can meet your material needs.

Processing content: Consider the main work you do, such as engraving, marking, cutting, or a combination. Different laser machines may differ in their functions.

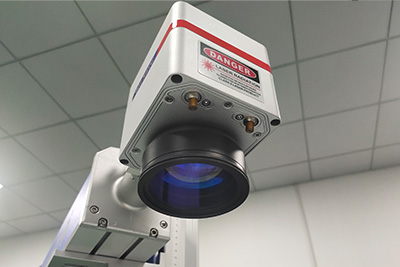

2. Laser type

Fiber laser machine: Suitable for processing metal materials, with high precision and high speed, and low maintenance.

CO2 laser machine: Usually used for non-metallic materials (such as wood and plastic), suitable for large-area cutting and engraving.

Other types (such as YAG laser): Suitable for certain materials such as aluminum alloys and stainless steel, but are mostly used in specific applications.

3. Power and speed

Power affects the speed and depth of laser processing. Higher-power laser machines can handle thicker materials or more complex designs.

Determine whether the processing speed meets your production efficiency requirements.

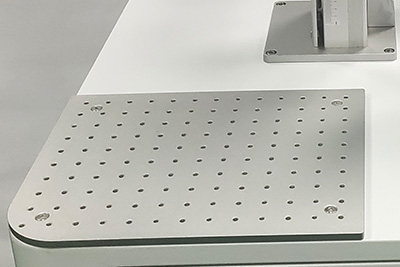

4. Size and work area

Choose the appropriate machine based on the size of the material you need to process and the area you need to engrave. Make sure the laser engraver’s work area can accommodate your maximum work size.

5. Budget

The price of laser engravers can often vary greatly depending on your budget. In addition to the initial purchase cost of the machine, consider the long-term maintenance costs and consumables costs.

6. Accuracy and resolution

Choose a machine with high accuracy and resolution, especially for applications that require detailed engraving, to ensure that the desired exquisite results can be achieved.

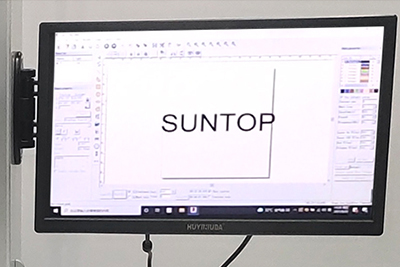

7. Ease of operation

Confirm that the machine is easy to operate and has a user-friendly interface. Modern laser engravers are usually equipped with intuitive software and control systems that can reduce the learning curve.

8. Maintenance and service support

Learn about the after-sales service and technical support provided by the manufacturer to ensure that the machine can receive timely maintenance and troubleshooting support during use.

9. Supporting software

Evaluate whether the software that comes with the machine is easy to use and compatible with your existing design software (such as CAD/CAM, etc.). Good software support can improve work efficiency and design flexibility.

By comprehensively considering the above factors, you can more confidently choose the laser engraving machine that suits your needs to improve production efficiency and processing quality. Click here to consult Suntop Laser today for professional advice and opinions.