Product Parameters Samples Video

Features of laser engravable metal

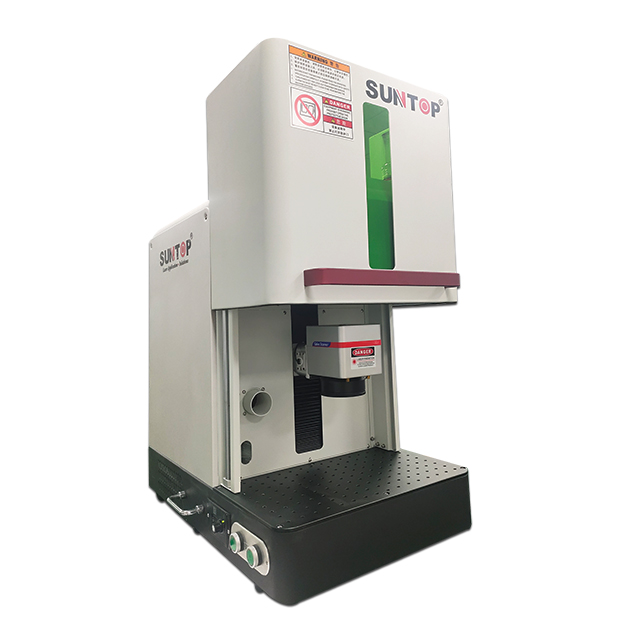

1. Adopt European CE standard laser protection glass fully enclosed design, laser processing is visualized, and the operation is safer.

2. The CNC full-cabinet small laser marking machine is equipped with electric lifting focus and emergency stop button, which is more convenient.

3. The built-in red light is used to preview the marking position, making it easier and more accurate to find the laser focus.

4. Adopt high-precision famous brand wavelength F-theta lens, which can realize high-speed and high-precision laser marking, and the text and image will not be distorted for a long time.

5. Equipped with an exhaust and dust removal system to keep the working environment clean and prolong the service life of optical components.

6. Humanized operation, long-term operation without failure, fully meet the needs of continuous industrial work.

Details of laser engravable metal

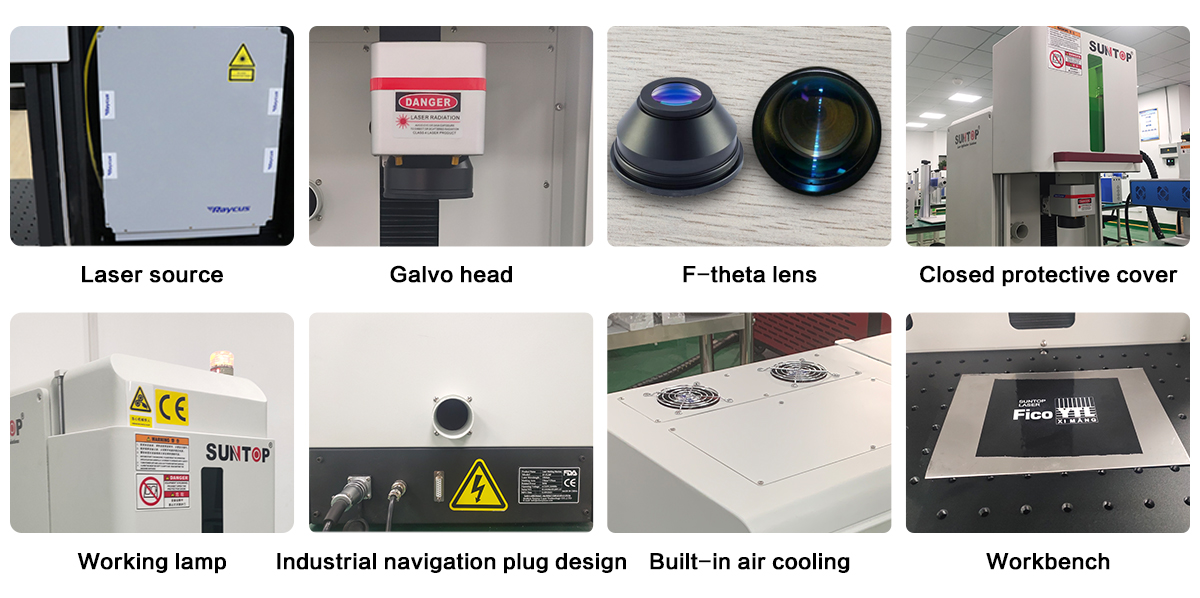

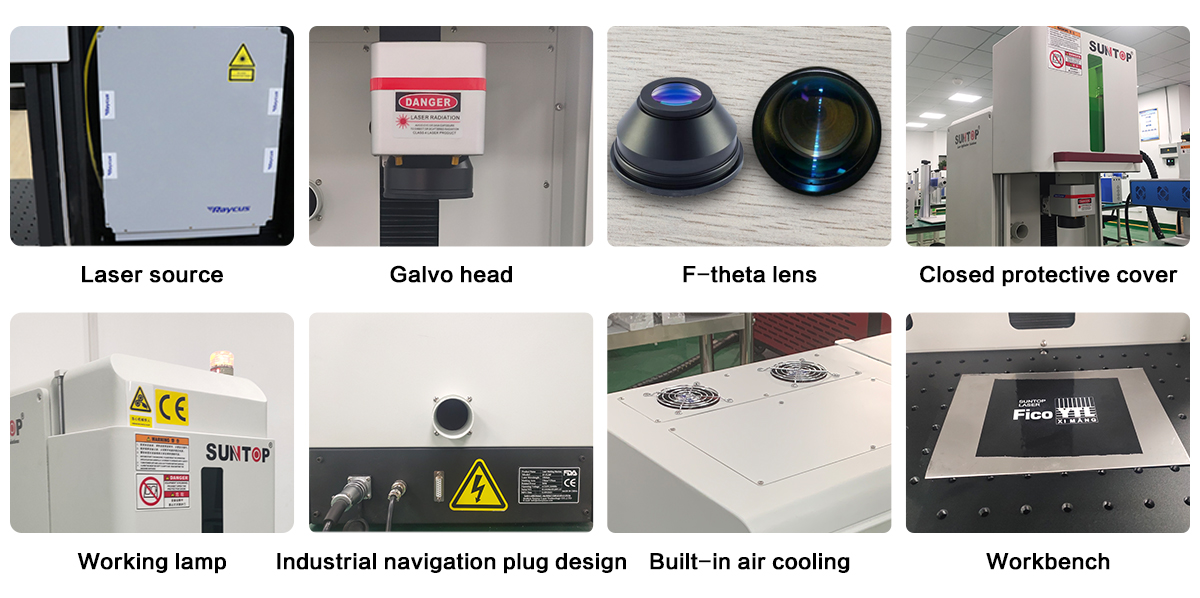

1. Laser source

Using MAX, Raycus, JPT and other brand lasers. Good beam quality, stable performance, service life up to 100,000 hours), maintenance-free.

2. F-theta lens

Sino-Galvo scanning head has good operational stability, high positioning accuracy, fast marking speed and strong anti-interference ability.

3. F-theta lens

Strong light transmission, uniform light beam, fine light, suitable for various harsh working environments.

4. Enclosed protective cover

Humanized design, closed safety cover, flexible adjustment of lifting speed.

Advantages of laser engravable metal

1. High precision

Metal laser engraving has a very high precision, can achieve micron-level processing accuracy, suitable for products requiring high detail processing.

2. Fast processing

Compared with traditional mechanical processing, metal laser engraving has the advantage of rapid processing, improving production efficiency and saving time costs.

3. Non-contact processing

Laser engraving is a non-contact processing technology, will not cause material deformation or damage, to ensure the stability of the processing effect.

4. Flexibility

Metal laser engraving can be flexibly processed according to the design requirements, applicable to a variety of complex shapes processing needs, with a strong degree of design freedom.

5. Environmental protection and energy saving

Laser engraving process without the use of chemical solvents, no waste gas, waste water emissions, in line with environmental requirements, energy saving and emission reduction.

Laser engravable metal application

Application materials

Suitable for working with most metal marking applications such as gold, silver, stainless steel, brass, aluminium, steel, Iron titanium etc, and can also mark on many nonmetal materials,such as ABS, Nylon, PES, PVC etc.

Application industry

Metals, alloy, oxide, ABS, epoxy resin, printing ink, etc, which are widely applying for electronics, jewelry, automobiles, communication products, phone keys, plastic translucent keys, jewelry products, key chain, electronic components, integrated circuits (IC), electrical appliances, buckles cookware, stainless steel products and other industries.

Parameters of laser engravable metal

Model | ST-FL20PF | ST-FL30PF | ST-FL50PF |

Laser power | 20W | 30W | 50W |

Depth of single marking | 0.01mm | 0.03mm | 0.06mm |

Same pattern marking efficiency | 10s | 7s | 4s |

Whole machine power | 600W/h | 800W/h | 1000W/h |

Marking area | 70*70mm/110*110mm/150*150mm |

Laser wavelength | 1064nm |

Laser source | MAX Brand (Raycus can be choose) |

Control software | EZCAD |

Cooling mode | Air Cooling |

Working accuracy | ±0.002mm |

Marking speed | 0-7000mm/s |

Repetition frequency | 20-100KHz |

Minimum font for marking | 0.15mm |

Graphic format supported | AI, PLT, DXF, BMP, DST, DWG, DXP |

Working voltage | 220V±10%, 50/60Hz |

Applicable material | All metal (Stainless steel, Carbon steel, Brass, etc.) and some plastic (ABS, PVC,PES, ETC.) |

Net weight/gross weight (KG) | 75KG / 85KG |

Machine dimension | 750*530*910mm (L*W*H) |