Details Product Parameters Samples Video

Features of jewelry laser welder

1. Using ccd camera monitoring system, the picture is clear, the positioning is accurate and visible, and the welding points are more comprehensive.

2. Corrosion resistance, high temperature resistance, high photoelectric conversion rate, long service life of more than 100,000 hours

3. Humanized design of the work surface, large internal space, suitable for long hours of work without fatigue

4. The high-speed liquid crystal light valve is used to automatically shading, and the protective gas is output synchronously with the laser to ensure that the solder joints are beautiful and will not be oxidized and discolored.

5. The ceramic laser cavity adopts imported brands, which is stable, reliable, corrosion-resistant and high-temperature resistant.

6. The unique YAG crystal cooling method improves the beam quality and the life of the xenon lamp.

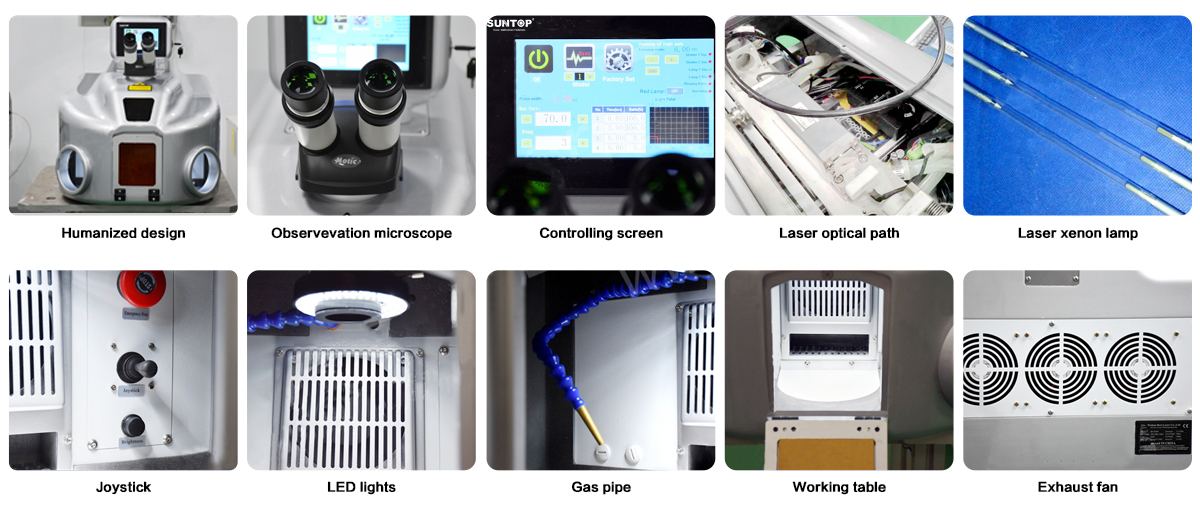

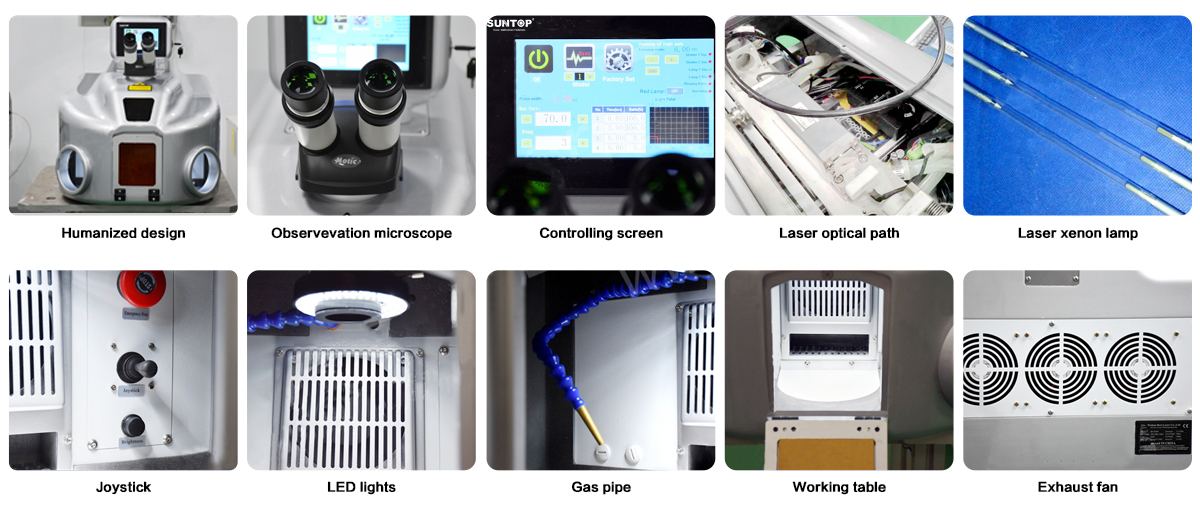

Details of jewelry laser welder

1. Observation microscope

China's top high-precision microscope (10×/20 times) is used for precise positioning and welding process.

2. Control screen

Built-in touch screen control system with high sensitivity and convenient parameter setting. Users can set different parameters (current, frequency, pulse...) according to different materials

3. Laser light path

Adopt the Morgan brand optical cavity imported from the UK to protect the laser source and prolong the service life.

It adopts Beijing famous brand crystal rod, designed by the Chinese Academy of Sciences, which is durable and not easy to damage.

4. Laser xenon lamp

Adopt Chinese famous brand original xenon lamp.

Lifespan: 8 million times, taking 8 hours a day as an example, a lamp can be used for 6-12 months.

The xenon lamp is the power source of the laser. When the xenon lamp is used up, just replace it with a new one.

5. Joystick

Users can also adjust the position of the cursor and set parameters by moving the joystick when welding. (emergency top/joystick/brightness)

6. LED lights

360° LED lights, all-round lighting, the brightness of the LED lights can be adjusted according to the comfort of the eyes, making work easier.

7. Duct

The continuous output is stable, preventing oxidation and blackening of products during the welding process, and the torch is flexible and fully adjustable.

8. Exhaust fan

There is an exhaust fan on the back, which can effectively prevent the machine from overheating due to prolonged use. There is a water cooling system inside the machine.

Advantages of jewelry laser welder

1. Fast speed, high efficiency, large depth, small deformation, small heat-affected area, high welding quality, non-polluting welding joints, high efficiency and environmental protection.

2. No filler solder, reliable joints, small deformation of workpiece, beautiful molding.

3. Large internal space, convenient for placing laser spot welding tools and fixtures.

4. Energy, pulse width, frequency, spot size, etc. can be adjusted in a wide range, which can achieve a variety of welding effects.

5. 24 hours continuous working capability, stable working performance of the whole machine.

6. The laser spot is finer to meet the needs of fine welding.

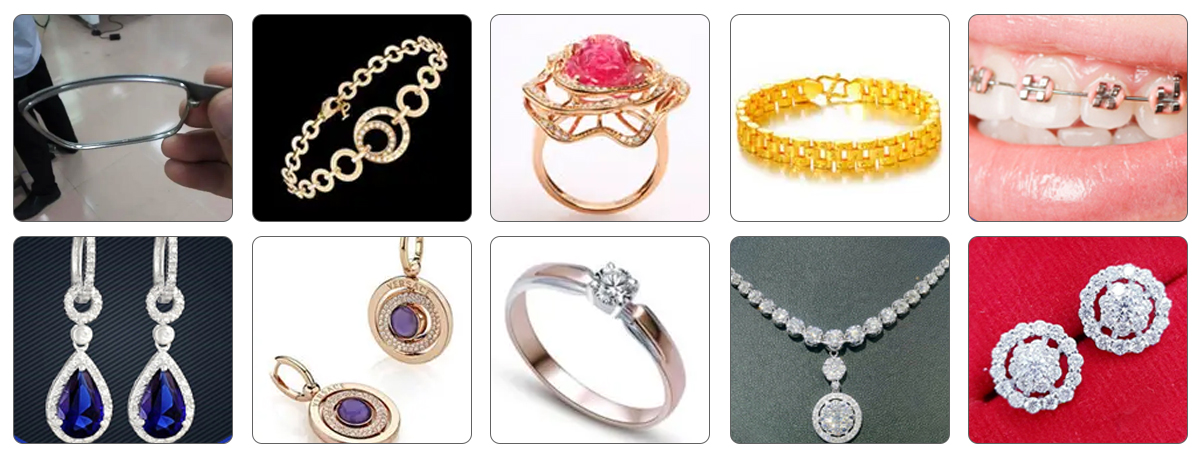

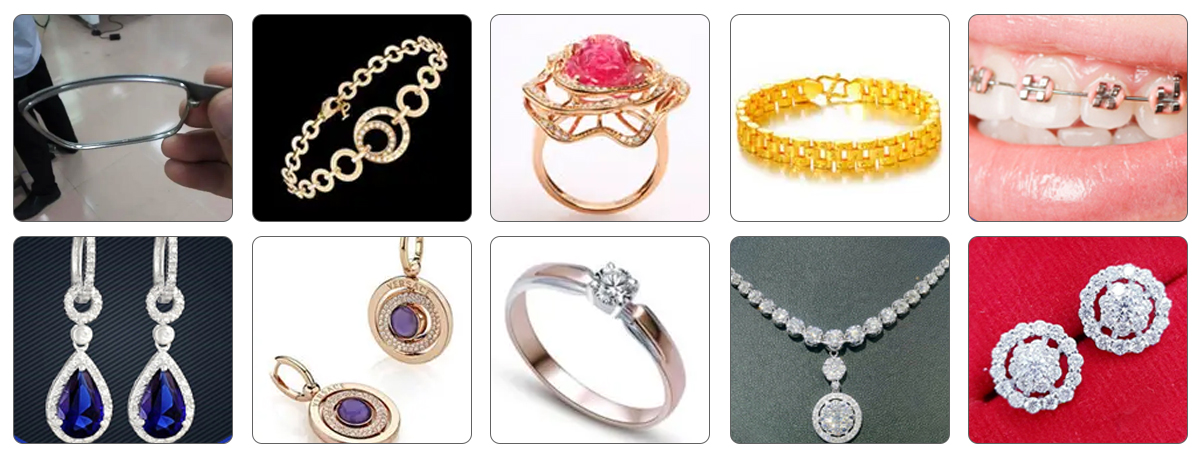

Jewelry laser welder application

Application materials

Mainly used for hole filling spot welding of gold and silver ornaments, also can be used for cold welding of high alloy steel, hot forged high alloy steel, nickel tool steel, high-grade steel, copper alloy, beryllium copper, high toughness aluminum alloy, gold, silver and other metal materials.

Application industry

Suitable for many industries and fields such as jewelry, electronics, communication, hardware, clocks and watches, medical equipment, aluminum alloy dentures, instruments, machining, automobiles, etc.

Parameters of jewelry laser welder

Model | ST-WY150 |

Max. laser power | 150W |

Laser wavelength | 1064nm |

Total power consumption | 5KW |

Pulse energy | 50J |

Laser focus | 110mm |

Laser pulse repeatable frequency | ≤0.1-20Hz |

Observation system | Microscope 10X or CCD camera |

Cooling | Internal water cooled |

Water T.M Protection | 10-30 degree |

Laser pulse width | ≤20ms |

Laser protection gas | Argon |

Controls | Touch screen or joystick |

Power supply | AC220V±10%,50/60Hz |

Dimension | 900*500*600mm |

Net weight/gross weight | 80KG/100KG |