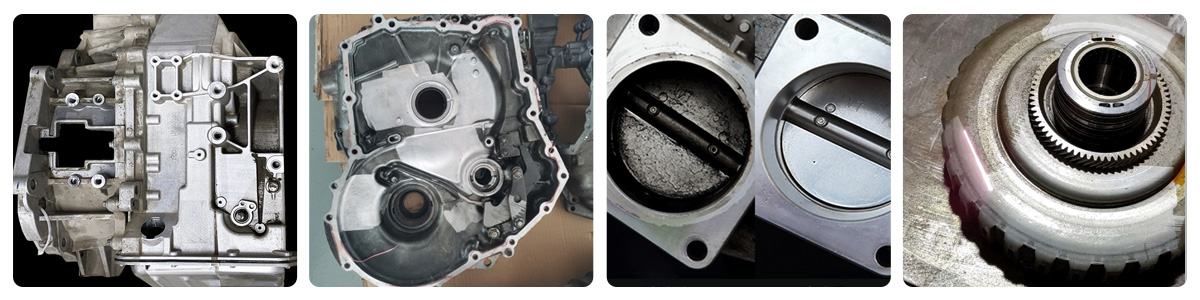

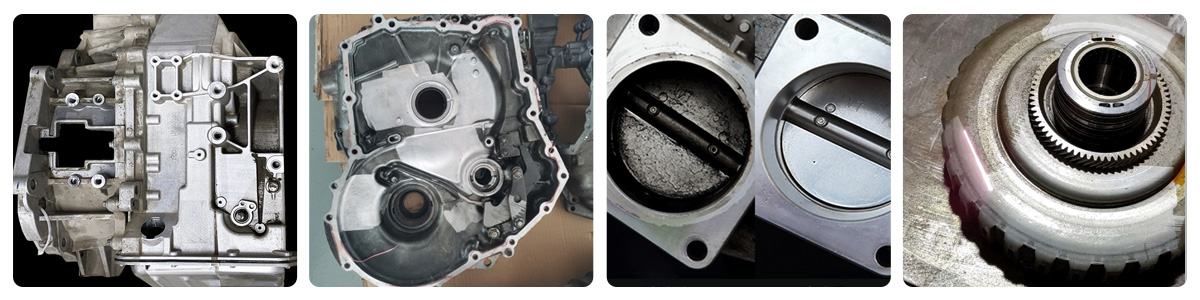

Handheld laser cleaning machine is an efficient and environmentally friendly cleaning equipment, widely used to remove various types of oil stains. The following are strategies for using laser cleaning machines in dealing with oil stains:

1. Adjust laser parameters

a. Power setting

Choose the appropriate power: adjust the power of the laser according to the type and thickness of the oil stain. Generally speaking, thicker oil stains or oil stains with strong adhesion require higher laser power, while thin oil stains can use lower power.

Risk of too high power: Too high power may damage the substrate, so it is necessary to conduct a small-scale pilot before cleaning to find the appropriate power.

b. Frequency

Frequency adjustment: The frequency determines the number of laser pulses. For oil stains that are more difficult to remove, appropriately increasing the frequency can increase energy concentration and enhance the cleaning effect.

Experiment with different frequencies: Use different frequencies for practice, observe the output effect, and find the best frequency combination.

c. Pulse width

Pulse width affects the heat-affected zone: Longer pulse widths may increase the heat-affected zone, thereby damaging the substrate; while shorter pulse widths help reduce thermal effects.

Adjust according to the characteristics of oil stains: Select the appropriate pulse width according to the thickness and composition of the oil stains to ensure maximum cleaning efficiency while protecting the substrate.

2. Parameter optimization for different types of oil stains

Motor oil: Use medium power and higher frequency laser settings, and the pulse width can be appropriately shortened to avoid damage to the substrate.

Lubricating oil: Due to its strong viscosity, use higher power, moderate frequency and short pulse width to ensure decontamination.

Paint residue: Increase power, moderate frequency and longer pulse width to fully destroy the adhesion of the paint.

Industrial oil stains: Multiple tests are required to combine power and frequency to ensure the best decontamination effect.

Animal and vegetable oils: Use lower power and frequency to avoid damage to the substrate.

3. Operation tips

a. Cleaning angle

Appropriate angle: Choose an angle perpendicular to the surface or slightly inclined for cleaning, which can improve the energy concentration of the laser and the cleaning effect.

b. Distance control

Maintain a reasonable distance: Depending on the type of oil stains, the distance between the equipment and the target surface is usually kept at 10-30 cm to achieve the best cleaning effect.

c. Speed control

Slow movement: Maintain an appropriate movement speed during the cleaning process. Too fast may lead to incomplete cleaning, while too slow may excessively affect the substrate.

4. Safety measures and precautions for use

Personal protective equipment (PPE): Ensure that operators wear laser protective glasses, high-temperature resistant gloves and protective clothing to deal with direct damage caused by the laser.

Surrounding environment cleaning: Remove flammable items in the operation area to ensure safety.

Equipment detection: Regularly check the laser cleaning machine to ensure that the equipment functions normally and avoid accidents.

5. Combination with other technologies

a. Use with chemical cleaning agents

When dealing with difficult-to-remove oil stains, you can consider pre-treating with appropriate chemical cleaning agents before laser cleaning, which can reduce the difficulty of laser cleaning and improve the overall cleaning efficiency.

b. Use advanced monitoring and control technology

Monitoring system: Use cameras or sensors to monitor the cleaning process in real time to ensure the cleaning effect and adjust parameters in time.

Automatic adjustment control: Combine AI and automatic algorithms to automatically adjust laser output parameters based on real-time feedback to meet the cleaning needs of different oil stains.

Handheld laser cleaning machines can significantly improve cleaning effects and safety by flexibly adjusting laser parameters, operating techniques, and reasonably coordinating with other cleaning technologies in the application of oil pollution, combined with safety protection measures. This cleaning process is not only efficient, but also environmentally friendly, and has become an important tool in the field of modern industrial cleaning. Click here for more information