With the advancement of Industry 4.0, handheld laser welding machines are more and more widely used in various industries. As an efficient and accurate welding tool, it not only improves the welding efficiency, but also reduces the labor intensity of workers. In this article, we will introduce in detail the application industry, advantages and disadvantages, purchase points of the handheld laser welding machine, as well as the solution to the problem of burnt lenses.

Application industries

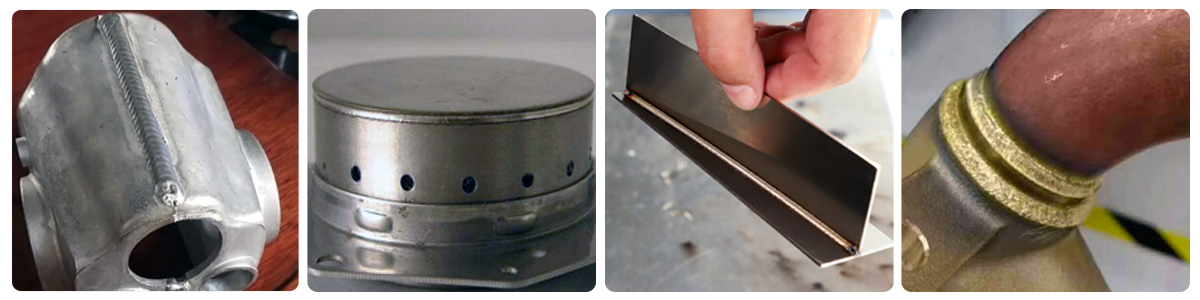

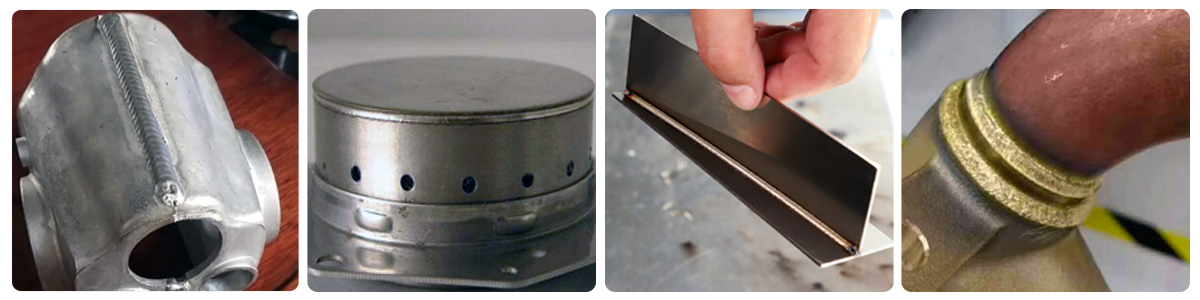

● Automobile manufacturing: handheld laser welding machine in the automobile manufacturing process can be quickly and accurately complete the body welding, improve production efficiency.

● Hoe appliance manufacturing: handheld laser welding machine is commonly used in refrigerators, washing machines and other home appliances sealing welding, to ensure that the sealing of the product and the aesthetic degree.

● Aerospace: In the aerospace field, the handheld laser welding machine can be used for welding aluminum alloy, titanium alloy and other high-strength materials to improve product quality.

● Shipbuilding: Handheld laser welding machines are widely used in the shipbuilding industry for welding hull structures, improving welding quality and efficiency.

● Petrochemical industry: In the petrochemical industry, the handheld laser welding machine can be used for welding high-pressure vessels, pipelines and other equipment to ensure the safety and stability of the equipment.

There are more industry applications here to explain one by one in addition to the above banking industry, there are sheet metal processing, chassis, water tanks, distribution boxes and other cabinets, doors, windows and fences, advertising signs, battery components, hardware molds, instruments and meters, mobile communications, medical equipment and other industries.

Advantages and disadvantages of handheld laser welding machine

Advantages

1. Efficient and fast: handheld laser welding machine with high power output, can quickly complete the welding task, improve production efficiency.

2. energy saving and environmental protection: compared with the traditional welding method, the handheld laser welding machine has a higher energy utilization rate and lower waste output, which is conducive to energy saving and environmental protection.

3. easy to operate: handheld laser welding machine operation is simple, easy to start, do not need a long time training.

4. Versatility: Handheld laser welding machine is suitable for welding of various materials and thicknesses, with strong adaptability.

Disadvantages: handheld laser welding machine price is high, one-time investment is large, handheld laser welding machine lens, electro-optical crystal and other components are easily damaged, maintenance is difficult.

So there is no solution to the program? Of course there is, the following is to say in detail

Handheld laser welding machine in the use of a problem often encountered in the process of burning lenses. Burnt lens is the phenomenon of lens damage due to prolonged exposure to high temperatures. This usually occurs when continuous high-intensity welding is performed and the lens cannot be cooled and protected in a timely manner. To solve this problem, the following measures can be taken:

● Use the automatic lens cleaning function: Choose a handheld laser welder with an automatic cleaning function that can automatically clean dirt and residue from the surface of the lens on a regular basis to ensure the transparency and cooling effect of the lens.

● The use of spare lenses: in the continuous high-intensity welding, you can prepare some spare lenses, timely replacement of the lens has been burned out to ensure the normal operation of the equipment.

How can I buy a suitable handheld laser welding machine?

1. Power selection: choose the right power range according to the actual demand. Generally speaking, 1500 watts to 3000 watts of power is suitable for most application scenarios.

2. Brand reputation: choose a well-known brand and products with good reputation to ensure quality and after-sales service.

3. Portability: Consider the size and weight of the equipment and choose a handheld laser welding machine that is easy to carry and use.

4. Safety: pay attention to the equipment's protection level, insulation level and other safety indicators to ensure the safety and reliability of the use process.

5. lens protection: choose the equipment with automatic cleaning and replacement of the lens function, in order to reduce the impact of lens damage on the welding quality.

6. Warranty: Choose products that offer a longer warranty period so that problems with the equipment can be resolved in a timely manner.

7. technical support: understand whether the manufacturer or distributor to provide technical support, operation training and other services, in order to get timely help and support in the use of the process.

8. price factor: when considering the purchase of handheld laser welding machine, you need to consider the price of equipment, performance, brand and other factors, in order to choose the best cost-effective products.

Suntop laser professional R & D, production of laser marking machine, laser welding machine, laser cutting machine, laser cleaning machine, engaged in the laser industry for 16 years, professional team, quality first, service-oriented trustworthy.