Details Product Parameters Samples Video

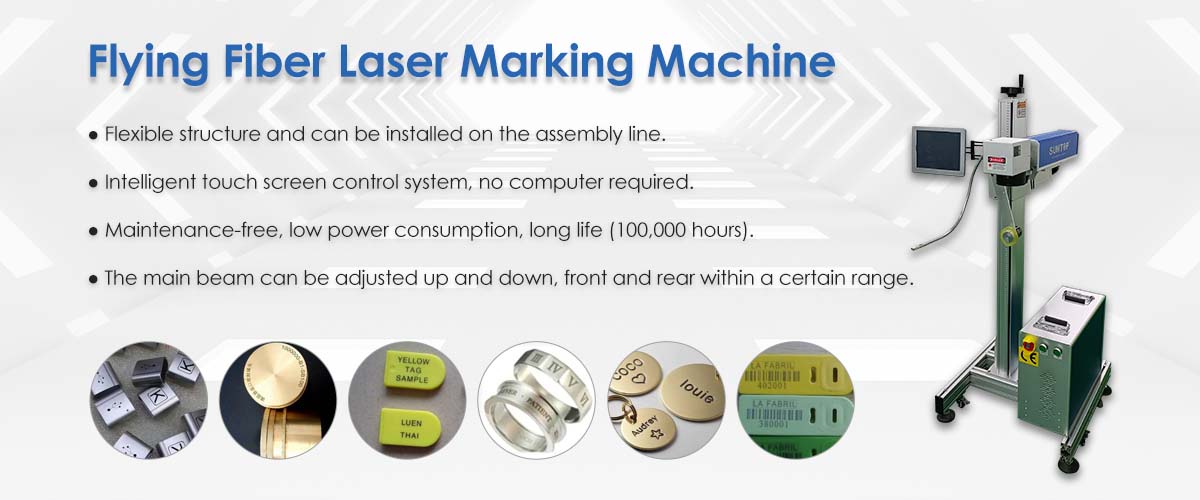

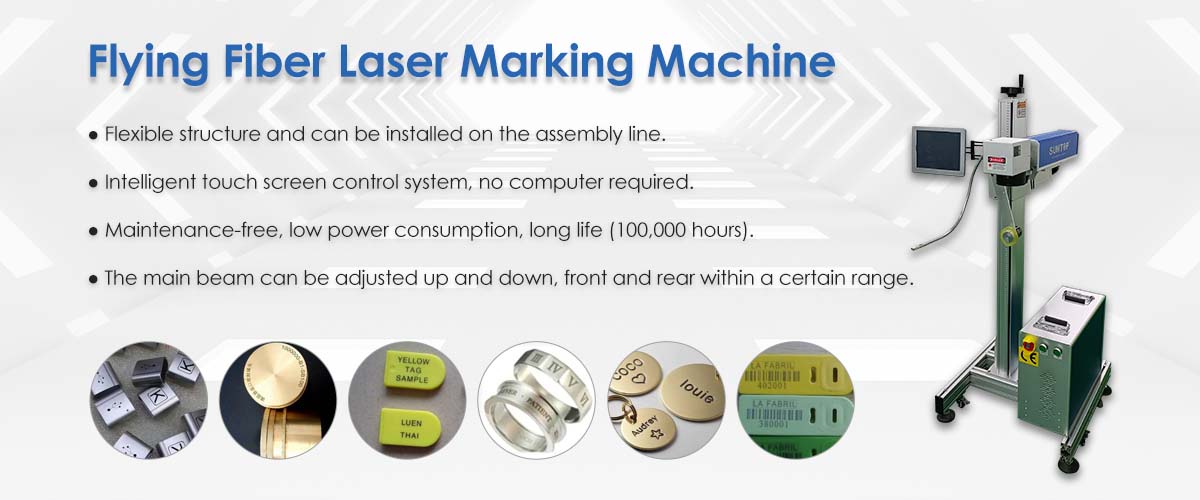

Features of fiber laser marking machine 50w

1. The whole machine has a flexible structure and a small footprint. It can be installed with professional brackets on the assembly line and is easy to adjust.

2. Built-in air cooling, no maintenance required. Intelligent touch screen control system, no need for computer, easy to use.

3. Compatible with a variety of focusing lenses, and can adjust a variety of light output directions to meet the needs of different application scenarios.

4. The stable and lightweight main beam lifting mechanism can adjust the main beam up and down, forward and backward within a certain range.

5. The electro-optical conversion efficiency is high, reaching more than 30%, low power consumption, and long life (100,000 hours), which saves a lot of processing costs for customers.

6. Professional industrial laser source, faster marking speed, good marking consistency, high reliability, can work 24 hours a day to meet the needs of large-scale processing and production.

Details of fiber laser marking machine 50w

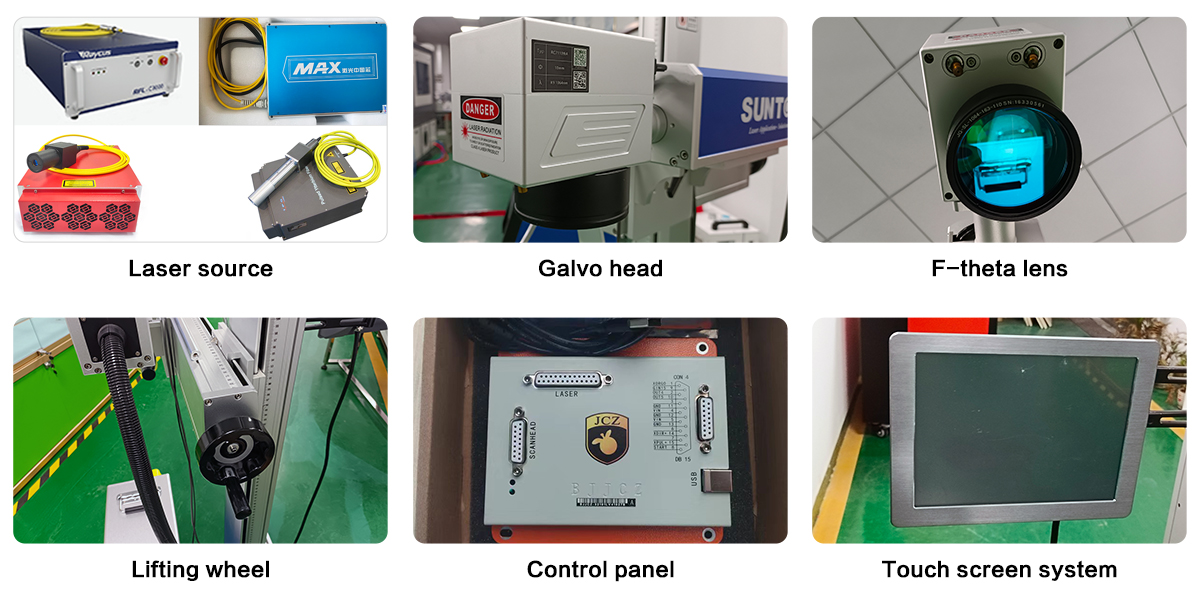

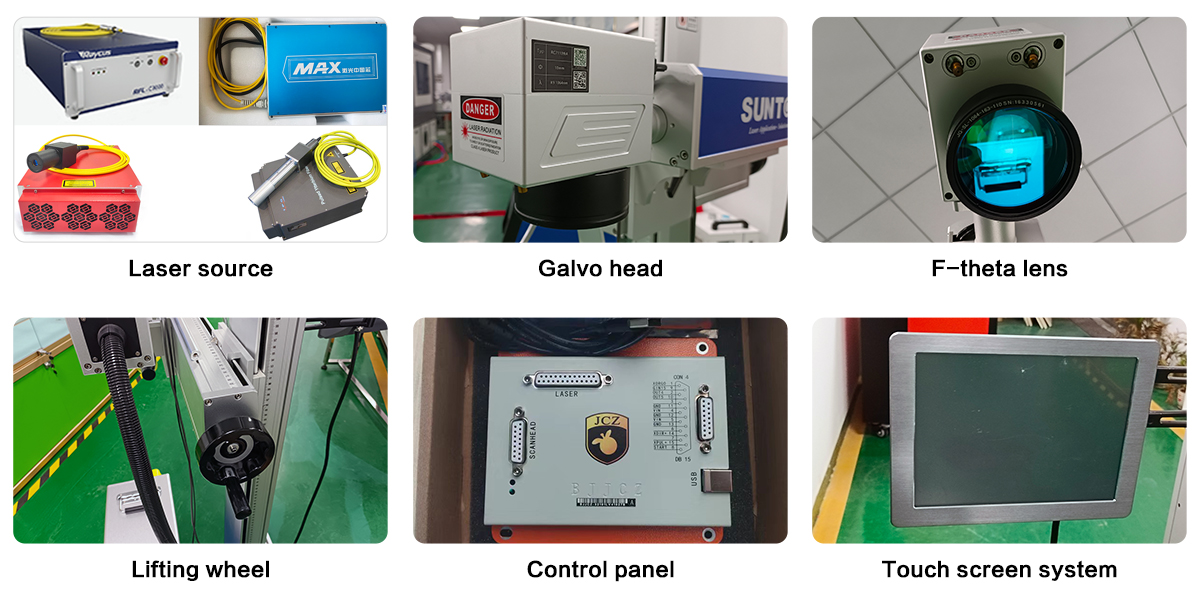

1. Laser source

Good beam quality, stable performance, long service life (100,000 hours), and maintenance-free. MAX, Raycus, JPT and other brands can choose.

2. Galvo head

Sino-Galvo scanner head has good operation stability, high positioning accuracy, fast marking speed and strong anti-interference ability.

3. F-theta scan lens

The use of quartz high-transparency coating field lens greatly improves the light-gathering ability of the edge beam, high light transmittance, and good marking effect.

4. Touch screen industrial computer

Touch screen experience, running without stuttering, and has high anti-magnetic, dust-proof, impact-proof and strong anti-interference ability, and can work continuously for a long time.

5. lifting wheel

The manual lifting wheel can be rotated to adjust the height of the lens to achieve the ideal marking focal length and effect.

5. Flying marking system

Based on the development of marking on the fly, it is very easy to edit any file pattern, etc., it can automatically produce batch numbers and serial numbers, and the software parameters can be modified flexibly.

Support customization

● According to the different needs of customers, it can match optical fiber, CO2, UV, RF and other models and fully automatic assembly line workbench, meet the flight standard system required by customers, realize assembly line operation, and improve production efficiency.

● The touch screen can be configured according to customer needs. High resolution, clear display, supports 14 languages such as English, Spanish, German, French, Italian, etc., very easy to use.

1. The machine adopts a special split structure, the laser head has an automatic induction function, and the workpiece is marked automatically after passing the laser head.

2. It is suitable for mass marking operations on the production line. It is suitable for marking serial numbers, dates and logos on pens, metals, craft gifts, advertising signs, model making, food packaging, electronic components, pharmaceutical packaging, pharmaceutical packaging, printed plates, shell plates, etc.

Fiber laser marking machine 50w application

Application materials

Suitable for working with most metal marking applications such as Gold, Silver, Stainless Steel, Brass, Aluminium, Steel, Iron Titanium etc, and can also mark on many nonmetal materials,such as ABS, Nylon, PES, PVC etc.

Application industry

Widely used in pharmaceutical packaging, wine packaging, beverage packaging, shell nameplates, craft gifts, electronic components, integrated circuits (IC), electrical appliances, mobile communications, hardware products, tool accessories, precision instruments, glasses clocks, auto parts, plastics Buttons, building materials, PVC pipes, medical equipment and other industries and mass production lines.

Parameters of fiber laser marking machine 50w

Model | ST-FL20F | ST-FL30F | ST-FL50F | ST-FL100F |

Laser power | 20W | 30W | 50W | 100W |

Max. marking range | 110*110mm/150*150mm | 200*200mm | 300*300mm | 300*300mm |

Depth of single marking | 0.01mm | 0.03mm | 0.06mm | 0.08mm |

Same pattern marking efficiency | 10s | 7s | 4s | 2s |

Whole machine power | 600W/h | 800W/h | 1000W/h | 1200W/h |

Laser wavelength | 1064nm |

Laser source | MAX Brand ( Raycus can be choosed) |

Control software | EZCAD |

Cooling mode | Air Cooling |

Working accuracy | ±0.002mm |

Marking speed | 0-7000mm/s |

Repetition frequency | 20-100KHz |

Minimum font for marking | 0.15mm |

Graphic format supported | AI, PLT, DXF, BMP, DST, DWG, DXP |

Working voltage | 220V±10% 50/60 Hz |

Applicable material | All metal (Stainless steel, Carbon steel, Brass,etc.) and some plastic(ABS, PVC,PES, ETC.) |

Net weight/gross weight (KG) | 75KG / 100KG |

Machine dimension | 450*750*1400mm (L*W*H) |