1. How can i place an order?

Please provide the details of your requirements as clear as possible. So we can send you the offer at the first time.

For further discussion, it is better to contact us with WhatsApp / WeChat / email / phone, in case of any delays.

2. What kind of display we provide?

We have laser marking machine / laser welding machine / laser cutting machine / laser cleaning / CO2 laser cutting and engraving machine / laser accessories for you choose.

3. How about the warranty?

We have 2 years warranty and lifelong maintenance.

4. What is your terms of delivery?

We accept EXW, FOB, CFR, CIF, DDU, DDP, etc. You can choose the one which is the most convenient or cost effective for you.

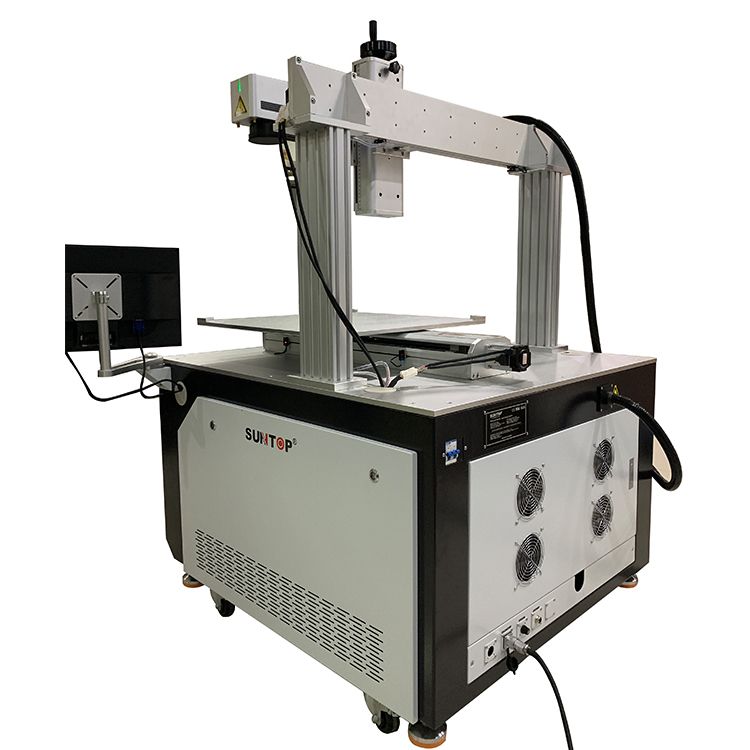

5. What is a wide-area laser marker?

A wide-area laser marker is a device designed specifically for laser marking in a large working area. It can efficiently and accurately mark large areas of workpiece surfaces and is suitable for a variety of materials.

6. What are the advantages of a wide-area laser marker compared to traditional marking methods?

Compared with traditional engraving or inkjet marking, a wide-area laser marker has the following advantages:

Higher marking quality: The laser marking font is clear and durable.

Non-contact processing: No physical damage to the workpiece.

Strong flexibility: It can be quickly adjusted according to different needs and is suitable for a variety of workpieces.

Cost savings: Although the initial investment is high, the subsequent maintenance cost is low and production efficiency is greatly improved.

7. Is the maintenance of a wide-area laser marker complicated?

The maintenance of a wide-area laser marker is relatively simple. Basic maintenance measures such as regular cleaning of the laser and optical components, checking safety protection and software updates can ensure the efficient and normal operation of the equipment.

8. How to choose a suitable wide-area laser marker?

Consider the following factors when choosing a suitable large-scale laser marking machine:

Marking area: Confirm that the equipment can meet the maximum marking area you need.

Material compatibility: Make sure the selected equipment can handle the material you need to mark.

Laser type: Select the appropriate laser type (such as fiber laser, CO2 laser, etc.) according to the required marking effect.

Equipment speed: Evaluate whether the marking speed of the equipment meets production needs.

Budget: Consider the purchase and subsequent maintenance costs of the equipment.

9. What are the common problems of large-scale laser marking machines?

Marking is not clear: It may be due to incorrect focal length or insufficient laser power.

Material deformation: It may be due to excessive laser power, and the laser parameters need to be adjusted.

Complex operation: Unfamiliarity with the operation interface can be solved through training or manual consultation.