Details Product Parameters Samples Video

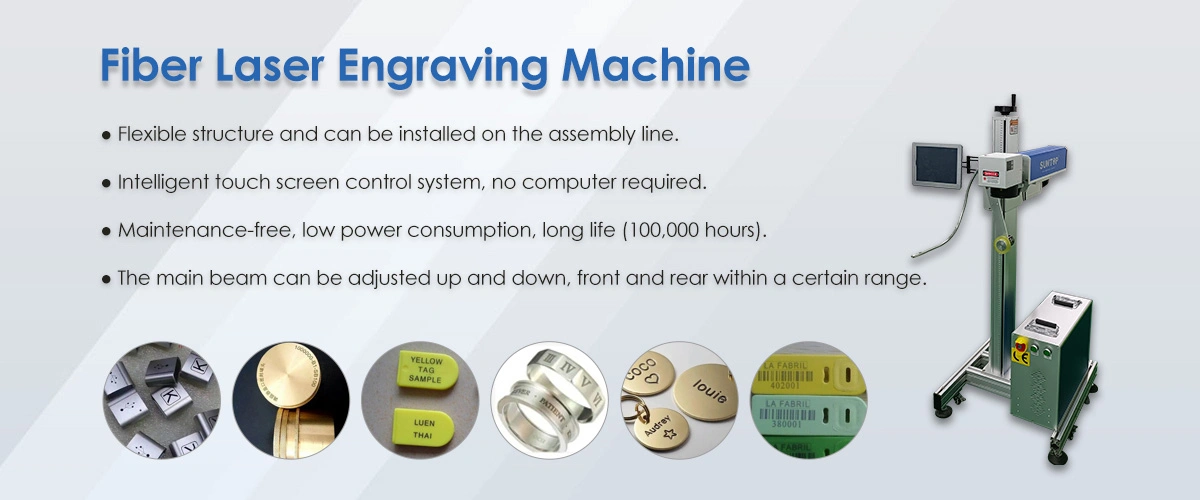

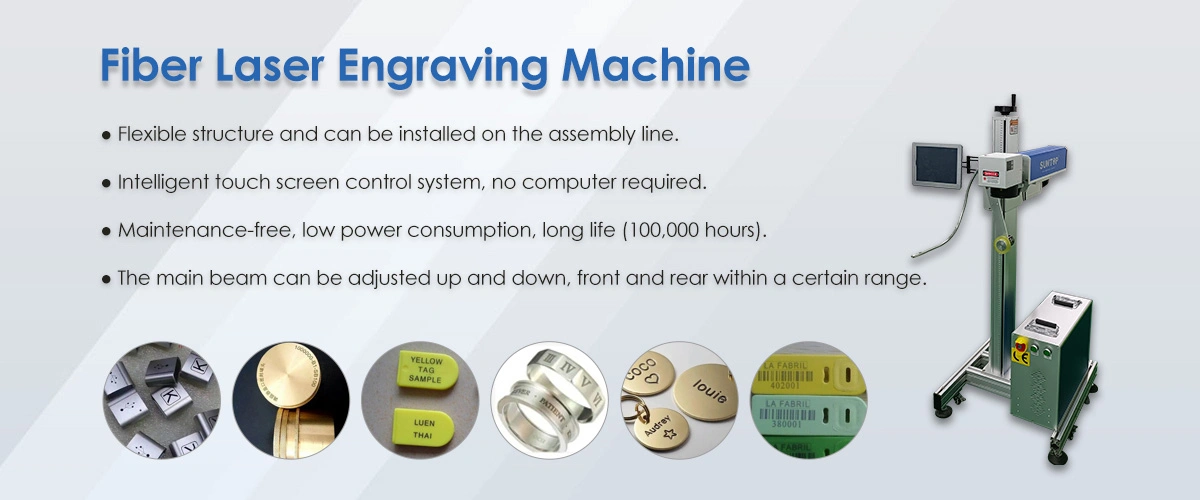

Features of automator laser marking

1. Flexible structure, small footprint, can be installed on the assembly line with professional bracket, easy to adjust.

2. Intelligent touch screen control system, no need for computer, easy to use.

3. Stable and light main beam lifting mechanism can adjust the main beam up and down, front and back within a certain range.

4. Adopting special split structure, the laser head has auto-sensing function, and the workpiece is marked automatically after passing through the laser head.

5. With short start-up time, narrow light pulse, high peak power, wide range of repetition frequency, no shadow and dotted line phenomenon for special material processing, etc., it can meet most of the marking needs Number of users.

Details of Automator Laser Marking

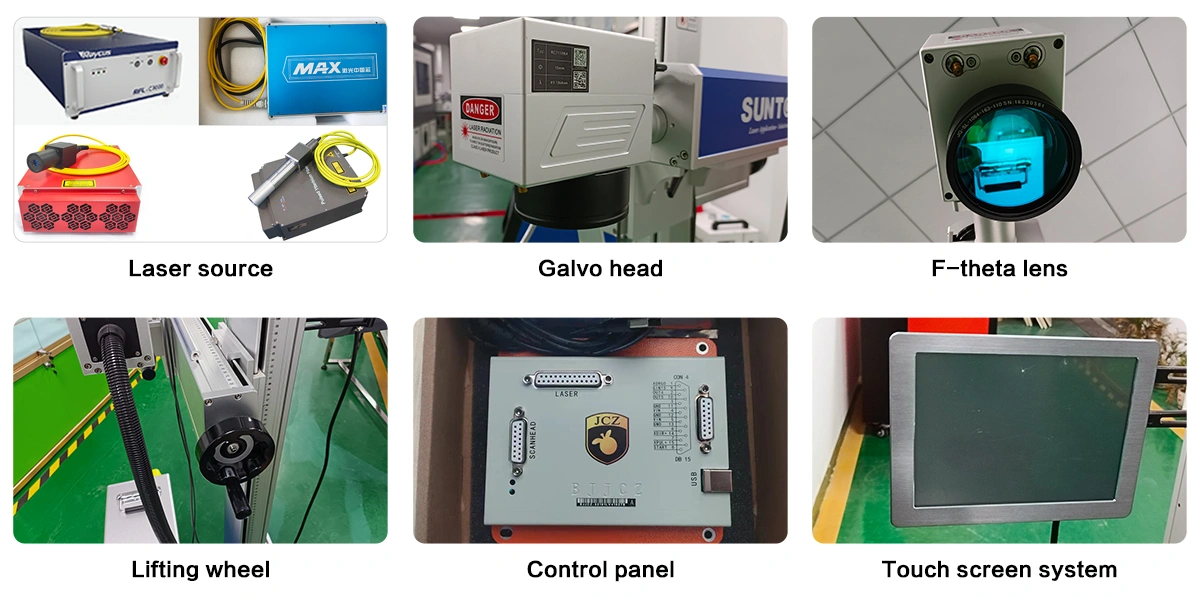

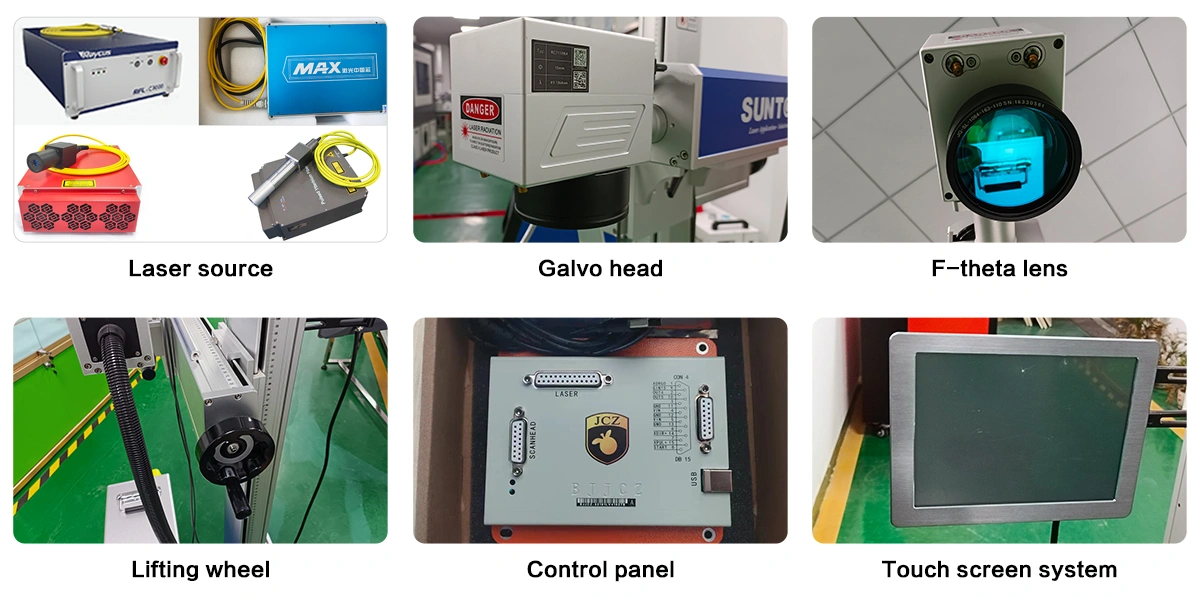

1. Fiber laser

Adopt high-quality pulsed fiber laser, which has good output laser mode and long service life, and is designed to be installed in the marking machine housing.

2. Galvanometer scanning system

The galvanometer scanning system consists of two parts: optical scanner and servo control. The whole system is designed and manufactured with new technology, new materials, new processes and new working principles.

3. Focusing system

The function of the focusing system is to focus the parallel laser beam on one point. It mainly adopts f-θ lens. Different f-θ lenses have different focal lengths, marking effects and ranges. Users can choose the lens model according to their needs.

4. Touch screen system

Intelligent touch screen control system, no computer required, more convenient to use.

Advantages of automator laser marking

Suitable for assembly line laser automatic marking machine for batch irregular marking in the fixture design and manufacturing difficulties caused by the material supply difficult, poor positioning, slow speed of the problem, to take the characteristics of the point of the way to be solved. This system can feed materials at will, position accurately and mark beautifully, which effectively improves the marking efficiency.

● Conveyor belt automatic transmission, automatic material drop, can be doubled to improve efficiency.

● When operating, you only need to put the workpiece on the conveyor belt, no need to care about the position.

● The equipment automatically locates the workpiece to ensure accurate marking position.

Stable energy, precise control and stable processing quality.

● Good beam quality, fine marking, good readability

● Can mark characters, barcode, 2D code, etc.

Support DXF, PLT, AL and other file formats.

Friendly operation interface, easy to use

● High efficiency of electro-optical conversion, compact structure and small appearance.

● Optional dust removal device, to protect the health of operators

● Reserved signal interface, convenient to become an organic whole with the existing production line.

● Designed for industrial production, long time continuous work, maintenance-free/no consumables/longer life.

Application materials of automator laser marking

Suitable for working with most metal marking applications such as Gold, Silver, Stainless Steel, Brass, Aluminium, Steel, Iron Titanium etc, and can also mark on many nonmetal materials,such as ABS, Nylon, PES, PVC etc.

Application industry of automator laser marking

It is widely used in many fields such as pharmaceuticals and health products, food and beverages, daily chemicals, tobacco, alcohol, electronics industry, and auto parts.

Parameters of automator laser marking

Model | ST-FL20F | ST-FL30F | ST-FL50F | ST-FL100F |

Laser power | 20W | 30W | 50W | 100W |

Max. marking range | 110*110mm/150*150mm | 200*200mm | 300*300mm | 300*300mm |

Depth of single marking | 0.01mm | 0.03mm | 0.06mm | 0.08mm |

Same pattern marking efficiency | 10s | 7s | 4s | 2s |

Whole machine power | 600W/h | 800W/h | 1000W/h | 1200W/h |

Laser wavelength | 1064nm |

Laser source | MAX Brand ( Raycus can be choosed) |

Control software | EZCAD |

Cooling mode | Air Cooling |

Working accuracy | ±0.002mm |

Marking speed | 0-7000mm/s |

Repetition frequency | 20-100KHz |

Minimum font for marking | 0.15mm |

Graphic format supported | AI, PLT, DXF, BMP, DST, DWG, DXP |

Working voltage | 220V±10% 50/60 Hz |

Applicable material | All metal (Stainless steel, Carbon steel, Brass,etc.) and some plastic(ABS, PVC,PES, ETC.) |

Net weight/gross weight (KG) | 75KG / 100KG |

Machine dimension | 450*750*1400mm (L*W*H) |