Details Product Parameters Samples Video

Features of portable fiber laser welding machine

1. Verify the position of the welding head using infrared positioning to ensure the accuracy of the welding process. This results in a smoother and more aesthetically pleasing weld seam, making it easier to grind and polish. Additionally, it requires little to no treatment after welding.

2. The handheld welding head is self-developed and equipped with various safety alarm devices, allowing for easy and flexible operation.

3. It is equipped with a high precision wire feeder, touch capacitive screen, 220V drive, and automatic wire feeding, ensuring a stronger and jam-free wire feeding process.

4. It is equipped with a 10m imported optical fiber, which overcomes the limitations of table space and allows for flexible and convenient outdoor and long-distance welding.

5. It is equipped with a double protection function (patented technology) for the water and gas circuit, effectively preventing damage to the laser lens or optical components caused by operator error. This significantly reduces the machine's failure rate and extends the lifespan of consumables.

6. The system can store various process parameters, allowing for easy switching through the touch screen based on processing needs. This reduces the time required for parameter debugging.

Details of portable fiber laser welding machine

1. Laser welding head

Lightweight, only 0.8KG, flexible and convenient for welding metal parts of any shape, adjustable weld width, capable of long-distance welding up to 10 meters. Equipped with a safety temperature monitoring system.

2. Operation interface

Multilingual intelligent control panel, flexible adjustment of welding parameters, multiple sets of welding parameter libraries, cumulative timing of light output, etc.

3. Automatic wire feeding system

Touch screen design, automatic wire filling, fully digital design, supports stainless steel and aluminum wires with diameters of 0.8mm, 1.0mm, 1.2mm, 1.6mm, and 2.0mm.

4. Laser source

We use custom-made fiber with a minimum core diameter of 20um, which has deeper penetration depth and a laser lifespan of up to 100,000 hours. It is maintenance-free and has Bluetooth functionality.

5. Chiller

Dual-cycle water cooling system provides better cooling for the laser source and welding head. The temperature control sensor uses imported brands.

6. Welding connection fiber

The 10-meter-long optical cable adopts an integrated design, effectively avoiding damage to the fiber and problems caused by moisture, greatly improving the service life of the laser components.

Advantages of portable fiber laser welding machine

1. High precision

Portable Fiber Laser Welding Machine adopts advanced laser technology, which can realize high-precision welding and ensure the quality and stability of the welded parts.

2. Portability

Compared with traditional laser welding equipment, Portable Fiber Laser Welding Machine is compact, easy to carry and move, suitable for welding needs in various occasions.

3. High Efficiency

Laser welding is fast, while Portable Fiber Laser Welding Machine can improve the working efficiency and save time cost while maintaining high quality welding.

4. Environmentally Friendly and Energy Efficient

The laser welding process does not require the use of additional welding materials, reducing the generation of waste, while the laser energy utilization is high, energy saving and environmental protection.

5. Multi-material application

Portable Fiber Laser Welding Machine can be used for welding various metal materials, including stainless steel, aluminum alloy, etc., with a wide range of applications.

6. High degree of automation

Through the intelligent control system, Portable Fiber Laser Welding Machine realizes the automation of the welding process, which reduces the manual operation and improves the production efficiency.

Single side weld thickness

Maximum melting | 1500W | 2000W | 3000W |

Stainless steel (mm) | 0.5-4 | 0.5-5/6 | 0.5-7 |

Mild steel (mm) | 0.5-4 | 0.5-6 | 0.5-7/8 |

Aluminum (mm) | 0.5-3 | 0.5-4 | 0.5-6 |

Brass/copper (mm) | 0.5-1.5 | 0.5-2 | 0.5-3 |

Galvanized sheet (mm) | 0.5-3 | 0.5-4 | 0.5-6 |

Iron (mm) | 0.5-4 | 0.5-6 | 0.5-7/8 |

Remark: Double weld thickness can be achieved if the material is welded from both sides in two times.

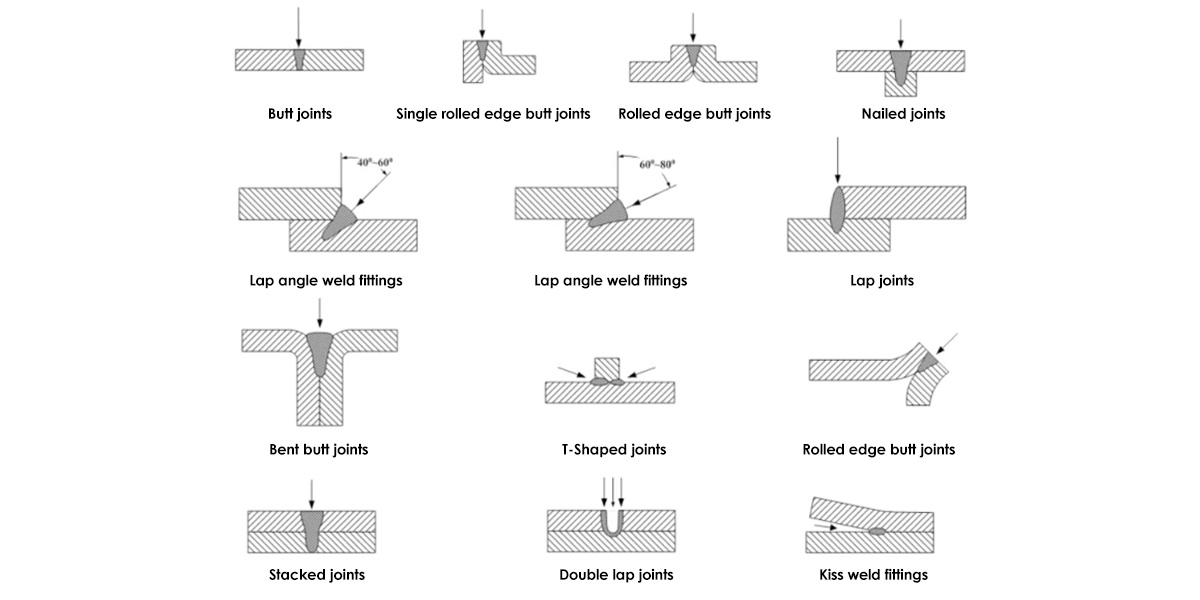

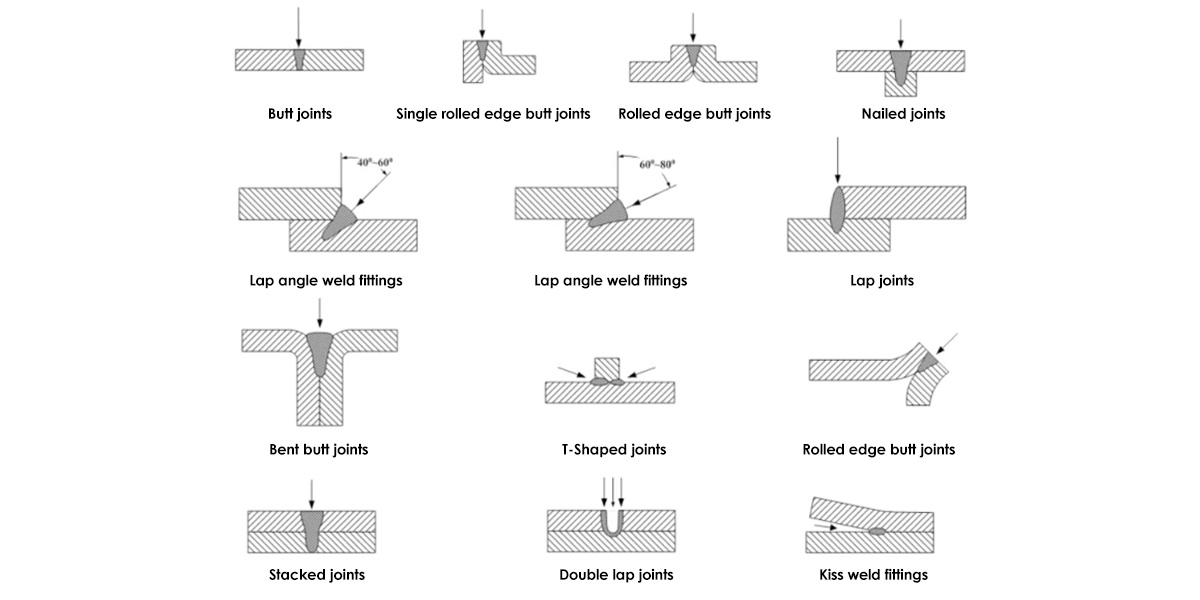

Welding method

A wide range of welding methods are available for welding at any angle, including overlay, butt, vertical, fillet, internal, external, etc. These methods can be used for a variety of workpieces, including complex welds and irregularly shaped workpieces, especially larger ones. These methods can be used to weld a wide variety of workpieces, including complex weld seams and irregularly shaped workpieces, especially larger workpieces.

Application materials

It can be used for welding stainless steel, carbon steel, copper, aluminum, gold, chromium, silver, titanium, nickel and other metals or alloys. It can also be used for various welding between different materials, including copper – brass, titanium-molybdenum, titanium- gold, nickel-copper, etc.

Application industry

Widely used in sheet metal processing, chassis, water tanks, distribution boxes and other cabinets, door and window guardrails, advertising signs, battery components, steel furniture, electronic appliances, metal molds, auto parts, instruments, mobile communications, medical equipment and other industries.

Parameters of portable fiber laser welding machine

Model | ST-FW1500H | ST-FW2000H | ST-FW3000H |

Power | 1500W | 2000W | 3000W |

Beam quality | ≤1.2 M⊃2; | ≤1.3 M⊃2; | ≤1.5 M⊃2; |

Laser wavelength | 1080nm |

Light exit mode | QCW /PWM /CW |

Max modulation frequency | 1000HZ |

Output power stability | <3% |

Aiming positioning system | Built-in Red Light |

Terminal type | QBH |

Delivery cable length | 10M (can be customized) |

Power supply | AC220V±10%, 50/60Hz |

Cooling system | Water Cooled with automatic pumping function |

working environment | Temperature 5-45°C /humidity 10-90% |

Applicable material | Almost all metal materials such as carbon steel, stainless steel, aluminum, brass and galvanized sheet. |

Net weight/gross weight | 140KG/170KG | 220KG/260KG | 270KG/320KG |

Machine size | 1000*500*1000mm | 1500*850*980mm | 1500*850*980mm |