Details Product Parameters Samples Video

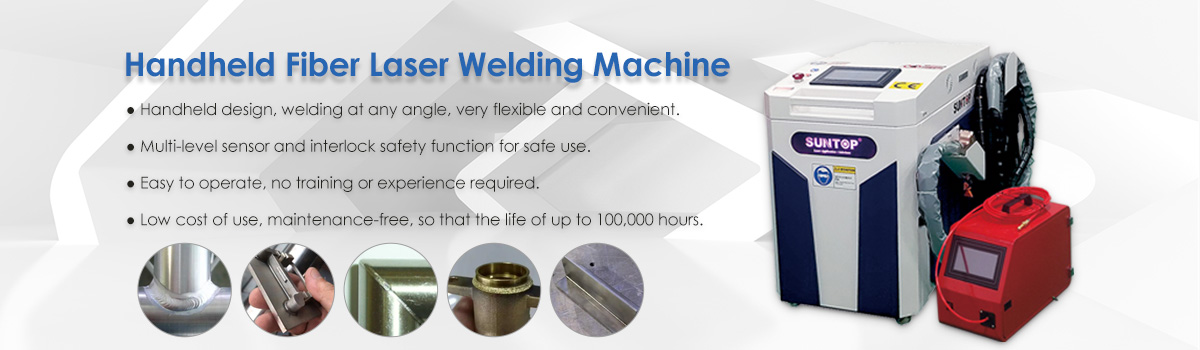

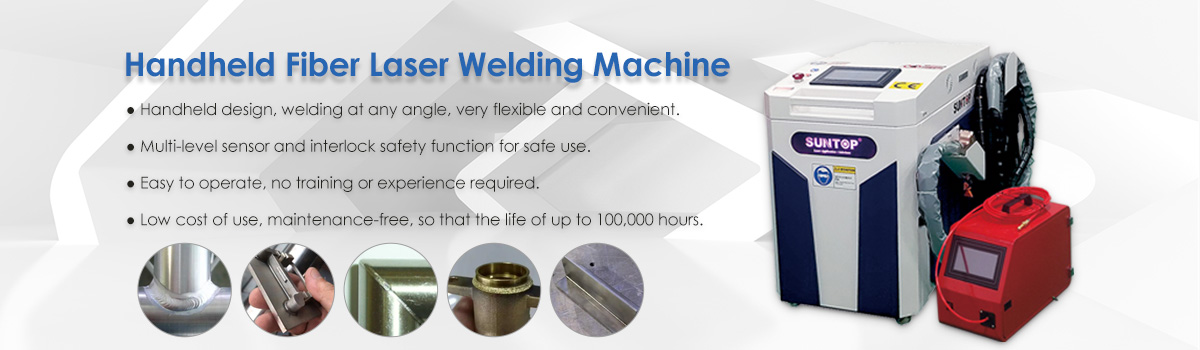

Features of laser soldering machine gold price

1. Use infrared positioning for calibrating and verifying the welding position in the welding process. This will result in more accurate welding positions and more beautiful weld seams.

2. The machine is equipped with a high precision wire feeder that has a touch capacitive screen, a 220V drive, automatic wire feed, stronger wire feed, and no wire jam.

3. The handheld welding head is self-developed and is light and delicate, making it easy to operate and allowing for welding at any angle.

4. The machine is equipped with a 10m imported optical fiber, which overcomes the limitation of workbench space. This allows for flexible and convenient outdoor and long-distance welding.

5. The machine has multiple safety alarm functions. The welding copper nozzle is only effective when it touches the metal, and the safety clip clamps the metal plate when the trigger switch is effective. Additionally, the welding copper nozzle will automatically lock the light after moving away from the workpiece. This ensures high safety for the machine and guarantees the absolute safety of the operator during work.

6. The machine has a double protection function for the water and gas circuit (patented technology). This effectively prevents damage to the laser lens or optical components due to operator misoperation, reducing the failure rate of the machine and extending the life of consumables.

Details of laser soldering machine gold price

1. Laser welding head

Lightweight, only 0.8KG, flexible and convenient for welding metal parts of any shape, adjustable weld width, capable of long-distance welding up to 10 meters. Equipped with a safety temperature monitoring system.

2. Operation interface

Multilingual intelligent control panel, flexible adjustment of welding parameters, multiple sets of welding parameter libraries, cumulative timing of light output, etc.

3. Automatic wire feeding system

Touch screen design, automatic wire filling, fully digital design, supports stainless steel and aluminum wires with diameters of 0.8mm, 1.0mm, 1.2mm, 1.6mm, and 2.0mm.

4. Laser source

We use custom-made fiber with a minimum core diameter of 20um, which has deeper penetration depth and a laser lifespan of up to 100,000 hours. It is maintenance-free and has Bluetooth functionality.

5. Chiller

Dual-cycle water cooling system provides better cooling for the laser source and welding head. The temperature control sensor uses imported brands.

6. Welding connection fiber

The 10-meter-long optical cable adopts an integrated design, effectively avoiding damage to the fiber and problems caused by moisture, greatly improving the service life of the laser components.

Advantages of laser soldering machine gold price

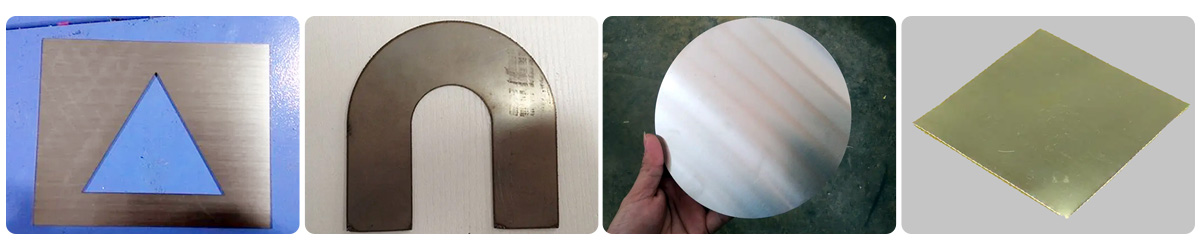

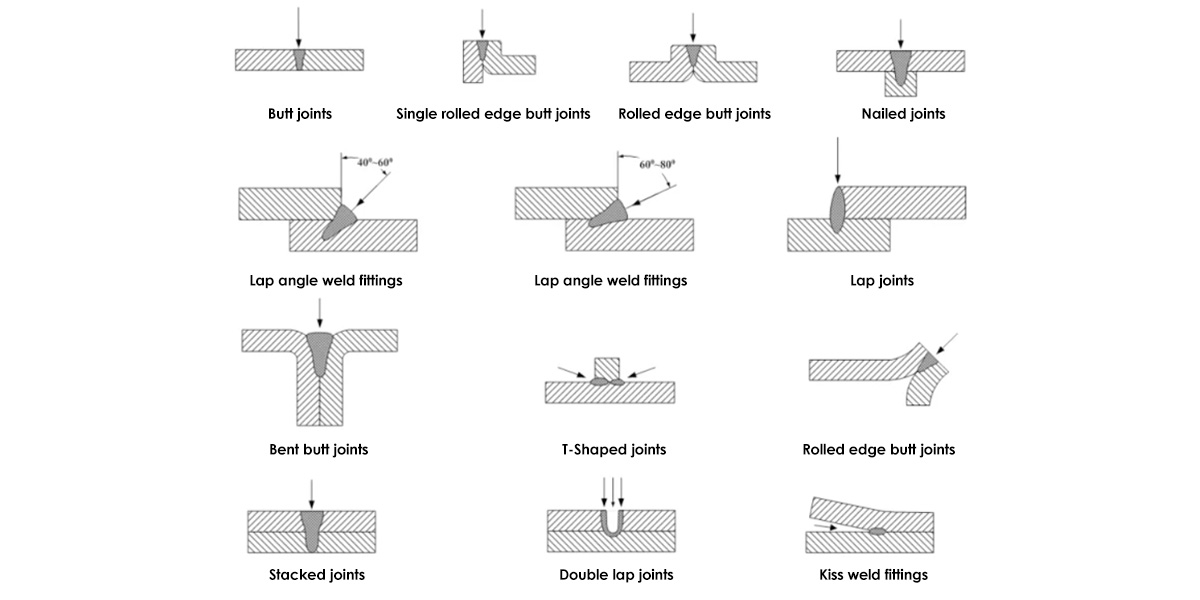

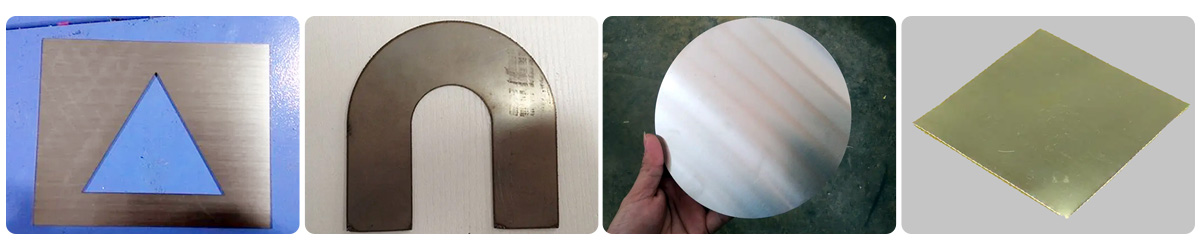

● Multiple Welding Methods

It can realize welding at any angle, such as lap welding, butt welding, vertical welding, flat angle welding, internal angle welding, external angle welding, etc. It can be used to weld all kinds of complex welding workpieces and large-scale workpieces with irregular shapes, realizing welding at any angle. In addition, cutting can be accomplished, and welding and cutting can be switched freely. It is very convenient to change the welding nozzle into a cutting nozzle.

● Good welding effect

Handheld laser welding is heat fusion welding. Compared with traditional welding, laser welding has higher energy density and can achieve better welding effect. The welding area has little heat influence, and it is not easy to deform, blacken, and have traces on the back. The welding depth is large, completely melted, firm and reliable, and the strength of the weld reaches or even exceeds that of the base material itself, which cannot be guaranteed by ordinary welding machines.

● No need to arrange the welding table

The laser welding machine does not require a welding table and takes up little space. For the diversification of welded products, the shape of the product is flexible and changeable, laser handheld welding machine can fully meet the needs of such production. The handheld laser welding machine eliminates the need for a precision welding table, low material and energy consumption, and low equipment deployment and maintenance costs.

● Simple operation

Handheld welding does not require a welder's certificate. Simple training to understand the basic parameters to get started. Now are intelligent control system operation of handheld welding equipment. By modifying the parameters on the touch screen, the welding of different materials can be realized, and the adaptability of the material is very strong.

Single side weld thickness

Maximum melting | 1500W | 2000W | 3000W |

Stainless steel (mm) | 0.5-4 | 0.5-5/6 | 0.5-6/7 |

Mild steel (mm) | 0.5-4 | 0.5-6 | 0.5-7/8 |

Aluminum (mm) | 0.5-3 | 0.5-4 | 0.5-5 |

Brass/copper (mm) | 0.5-2 | 0.5-2.5 | 0.5-3 |

Galvanized sheet (mm) | 0.5-4 | 0.5-5/6 | 0.5-6/7 |

Iron (mm) | 0.5-4 | 0.5-6 | 0.5-7/8 |

Remark: Double weld thickness can be achieved if the material is welded from both sides in two times.

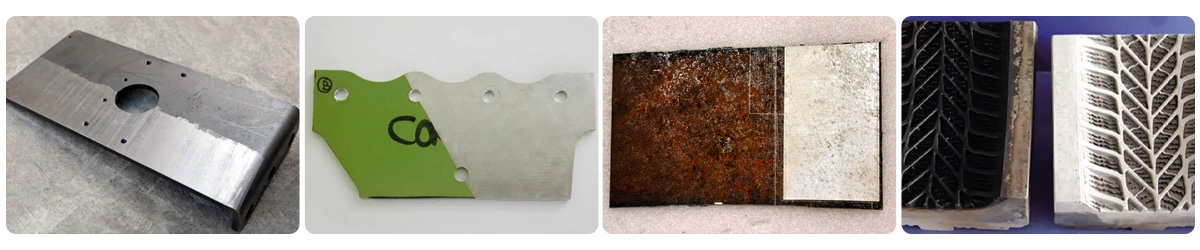

Other optional functions

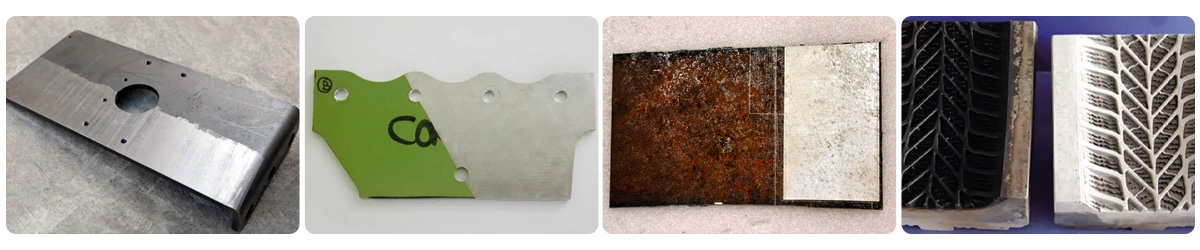

● Cleaning function

By replacing the laser nozzle and cleaning lens, the material surface cleaning function can be achieved, effectively removing rust, oxide layers, oil stains, etc. from the material surface without damaging its characteristics. It has the characteristic of non-contact and does not require cleaning solution, which can replace professional cleaning equipment.

● Cutting function

It can perform simple cutting, and welding and cutting can be freely switched by simply changing the welding copper nozzle to the cutting copper nozzle, which is very convenient.

It can cut metal sheets such as stainless steel, carbon steel, aluminum, aluminum alloy, and iron, with a maximum cutting thickness of about 2mm.

● Welding seam cleaning function

It can effectively remove impurities such as oxides, welding slag, oil stains, and dust generated during the welding process, making the weld surface clean. This not only helps improve the quality of the weld, but also enhances the strength and appearance of the weld. Laser cleaning has high precision and controllability, and can thoroughly clean the weld surface without damaging the base material.

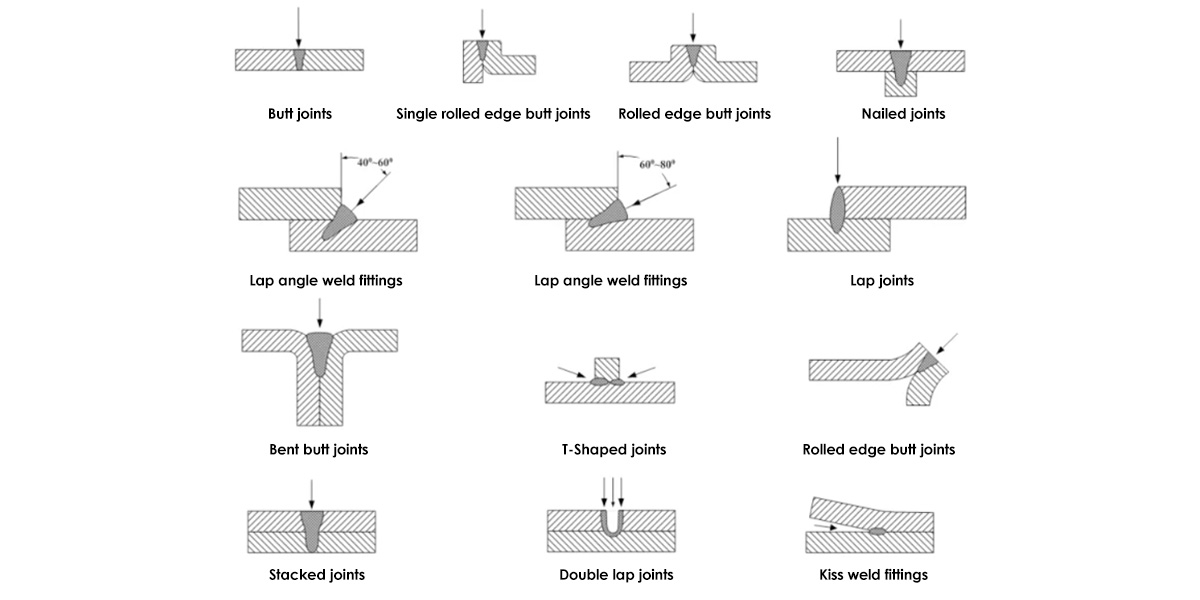

Welding method

There are various welding methods to choose from, allowing for welding at any angle, including overlay welding, butt welding, vertical welding, fillet welding, inside corner welding, outside corner welding, etc. These methods can be used for welding various workpieces, including complex welds and irregularly shaped workpieces, especially larger ones.

Application materials

It can be used for welding stainless steel, carbon steel, copper, aluminum, gold, chromium, silver, titanium, nickel and other metals or alloys. It can also be used for various welding between different materials, including copper – brass, titanium-molybdenum, titanium- gold, nickel-copper, etc.

Application industry

Widely used in cabinets, kitchen and bathroom, stairs and elevators, shelves, ovens, stainless steel doors and windows guardrails, distribution boxes, stainless steel home and other industries in the complex irregular welding process. Also widely used in kitchens, home appliances, advertising, molds, stainless steel doors and windows, handicrafts, home furnishings, furniture, auto parts and many other industries.

Parameters of laser soldering machine gold price

Model | ST-FW1500H | ST-FW2000H | ST-FW300H |

Power | 1500W | 2000W | 3000W |

Welding gun weight | 0.8 | 0.8 | 0.75 |

Max. welding thickness (mm) | ≤3 | ≤5 | ≤8 |

Max. welding seam width (mm) | 5 | 5 | 8 |

Laser type | Fiber laser (Suntop custom 20um welding exclusive) |

Laser detection method | Bluetooth wireless connection, Mobile App Monitoring |

Control panel language support | English, Spanish, German, French, Turkish, Italian, Russian, Vietnamese, Thai, Korean, Japanese, etc. |

Laser wavelength (nm) | 1064+5 |

Suitable welding materials | Carbon steel, stainless steel, aluminum, galvanized sheet metal, brass, iron and other metal materials |

Adapted welding methods | Spot welding, overlap welding, splice welding, fillet welding, lap welding etc. |

Laser power adjustment range (%) | 10-100 |

Cooling method | Advanced water-cooling, dual temperature control and automatic control |

Welding aiming preview method | Built-in Red-Light pointer |

Protection systems | Air pressure sensor and solenoid valve control |

Length of fiber optic cable (meter) | Standard 10 (can be customized 15) |

Welding shielding gas | Argon or nitrogen (air pressure approx. 6-8 bar) |

Working environment | Temperature 5-45 °C /humidity 10-90% |

Other optional support functions | Cleaning + cutting | Cleaning + cutting | Cleaning + cutting + weld bead cleaning |

Max. Cutting thickness (mm) | 1.2 | 1.5 | 2 |

Max. cleaning width (mm) | 40 | 40 | 120 |

Automatic wire feeder type (Universal with TIG wire)

| Single wire feed | Single wire feed | Support both the double wire feed and single wire feed |

Solid wire type (SS, Iron, AL, Brass) | 0.8, 1.0, 1.2, 1.6 | 0.8, 1.0, 1.2, 1.6 | 0.8, 1.0, 1.2, 1.6, 2.0, 2.5 |

Temperature control monitoring alarm | Yes | Yes | Yes |

Main machine consumables | Laser protective lenes, welding nozzles, welding wires |

Machine size (MM) | 686*425*611 | 750*1080*1000 | 750*1080*1000 |

Machine net weight (KG) | 110 | 220 | 240 |

Power supply requirement | 110V / 220V±10%, single phase | 380V±10%, three phase |

Total power consumption (Maximum) | 3500W | 4500W | 7000W |