Details Product Parameters Samples Video

Features of homemade laser welding machine

1. It adopts a fully enclosed optical path design, with advantages such as dustproof and good sealing; it can work continuously for a long time (up to 24 hours).

2. The self-developed Wobble welding head is small, lightweight, and easy to operate.

3. It has multiple safety alarm functions. The switch is only activated when the welding copper head contacts the metal, and the safety clamp clamps the metal plate. After removing the welding copper nozzle from the workpiece, the light will automatically lock. The machine has a very high level of safety, ensuring absolute safety for operators during work.

4. Equipped with a 10-meter original fiber optic cable, it overcomes the limitation of workspace on the workbench and enables outdoor welding and long-distance welding.

5. Suntop's patented technology water circulation protection system and auxiliary gas detection effectively extend the life of the laser lens and prevent damage to optical components caused by improper operation.

6. Infrared positioning verifies the position of the welding head during the welding process. The welding position is more accurate, the weld is smooth and beautiful, easy to polish, and no post-welding treatment is required or only simple treatment is needed.

Details of homemade laser welding machine

1. Laser welding head

Lightweight, only 0.8KG, can flexibly and conveniently weld metal parts of any shape, adjustable weld width, can perform welding at a distance of 10 meters. Equipped with a safety temperature monitoring system.

2. Operation interface

Multilingual intelligent control panel, can flexibly adjust welding parameters, multiple sets of welding parameter libraries, cumulative timing of light output, etc.

3. Automatic wire feeding system

Touch screen design, automatic wire feeding, fully digital design, supports 0.8mm, 1.0mm, 1.2mm, 1.6mm, 2.0mm diameter stainless steel and aluminum wire.

4. Laser source

Uses a customized minimum 20um core diameter fiber, stronger penetration, laser lifespan up to 100,000 hours, maintenance-free, with Bluetooth function.

5. Chiller

Dual circulation water cooling provides better cooling effect for the laser source and welding head, temperature control sensor uses imported brands.

6. Welding connection fiber

Built-in 10-meter long fiber optic cable design, effectively avoids the problem of fiber optic damage due to moisture, greatly improving the service life of the laser component.

Advantages of homemade laser welding machine

1. The welding speed is fast, being 5-10 times faster than traditional argon arc welding, which can reduce processing costs by about 30%.

2. It is easy to learn and operate, with no technical threshold requirements. Ordinary workers can operate it after a short training, making it easy to achieve high-quality welding results.

3. It is easy to use and flexible, allowing for the adjustment of the work station at any time. There is no need to fix the work station, making it free and flexible. It is suitable for a variety of work environment scenarios for welding.

4. It has a wide welding range, overcoming the limitations of workbench space. It can achieve outdoor welding and long-distance welding.

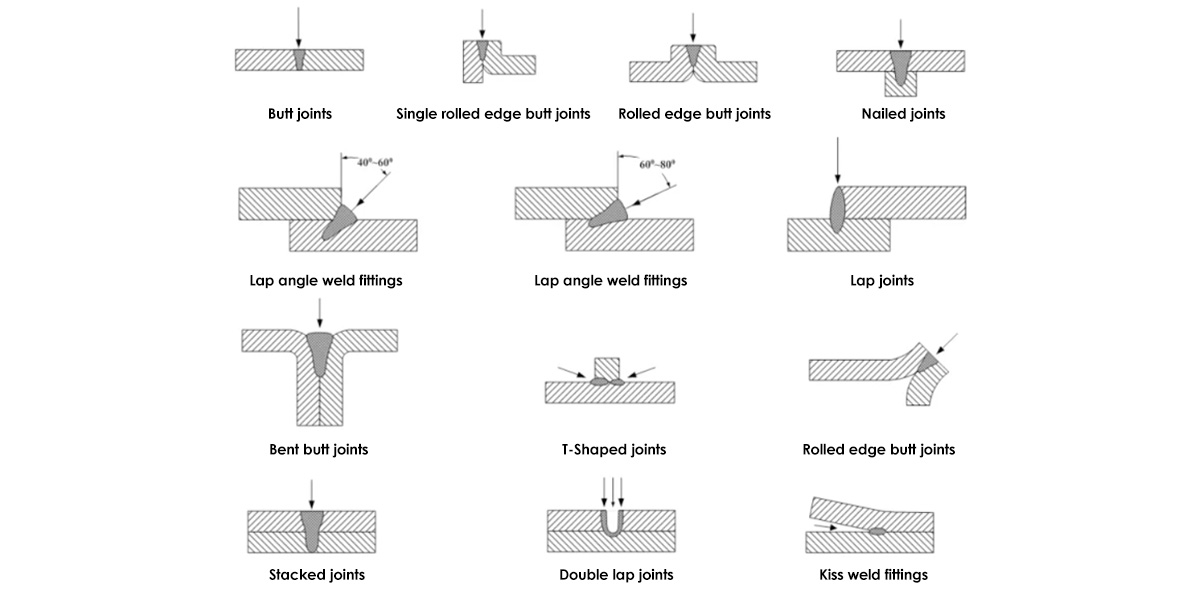

5. It offers multiple welding methods, allowing for any angle welding, stack welding, butt welding, vertical welding, flat angle welding, internal angle welding, external angle welding, etc. It can handle a variety of complex welding seam workpieces and larger workpieces with non-regular shapes.

6. It has concentrated energy, resulting in a small heat-affected area. There is no deformation or blackening, and it offers a large welding depth. The weld seam is fine and beautiful, with solid welding. The weld strength reaches or even exceeds the strength of the base material itself.

Other optional functions of homemade laser welding machine

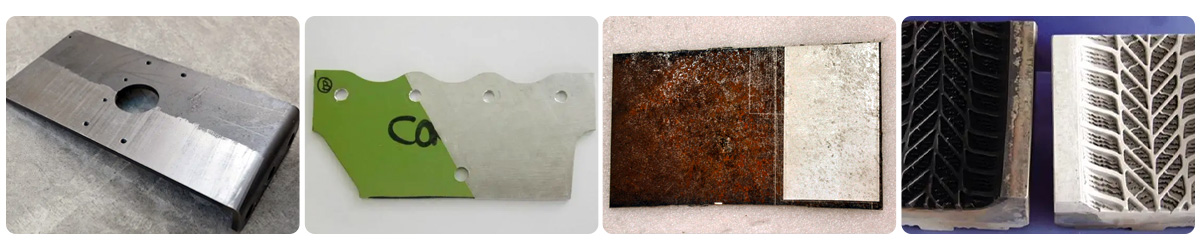

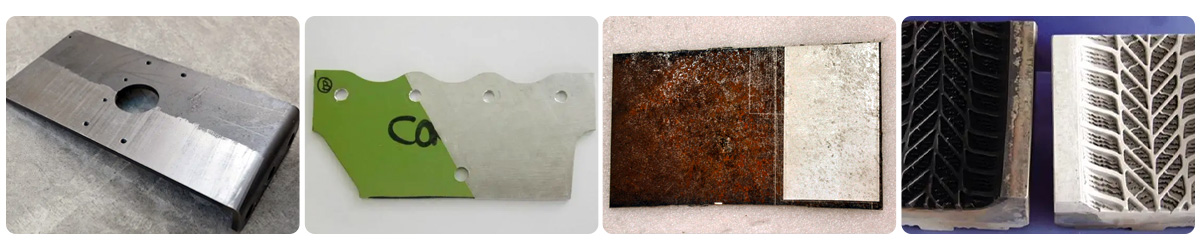

● Cleaning Function

By replacing the laser nozzle and cleaning lens, the material surface cleaning function can be achieved, effectively removing rust, oxide layers, oil stains, etc. from the material surface without damaging its characteristics. It has a non-contact feature, does not require cleaning solution, and can replace professional cleaning equipment.

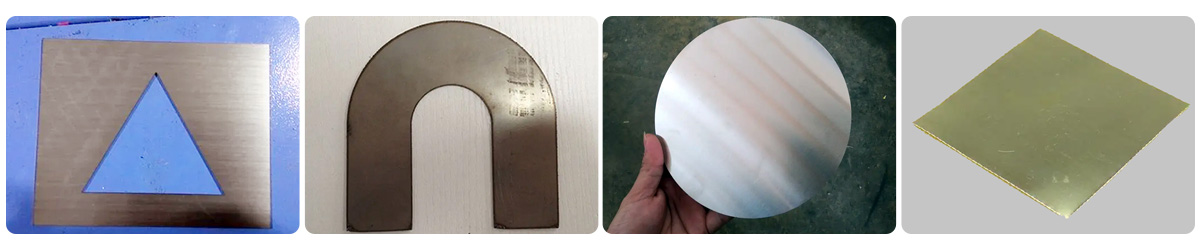

● Cutting Function

It can perform simple cutting, and welding and cutting can be freely switched by simply changing the welding copper nozzle to the cutting copper nozzle, which is very convenient.

It can cut metal sheets such as stainless steel, carbon steel, aluminum, aluminum alloy, and iron, with a maximum cutting thickness of about 2mm.

● Weld Seam Cleaning Function

It can effectively remove impurities such as oxides, welding slag, oil stains, and dust generated during the welding process, making the weld seam surface clean. This not only helps improve the quality of the weld seam but also enhances its strength and appearance. Laser cleaning has high precision and controllability, allowing thorough cleaning of the weld seam surface without damaging the base material.

Single side weld thickness

Maximum melting | 1500W | 2000W | 3000W |

Stainless steel (mm) | 0.5-4 | 0.5-5/6 | 0.5-6/7 |

Mild steel (mm) | 0.5-4 | 0.5-6 | 0.5-7/8 |

Aluminum (mm) | 0.5-3 | 0.5-4 | 0.5-5 |

Brass/copper (mm) | 0.5-2 | 0.5-2.5 | 0.5-3 |

Galvanized sheet (mm) | 0.5-4 | 0.5-5/6 | 0.5-6/7 |

Iron (mm) | 0.5-4 | 0.5-6 | 0.5-7/8 |

Remark: Double weld thickness can be achieved if the material is welded from both sides in two times.

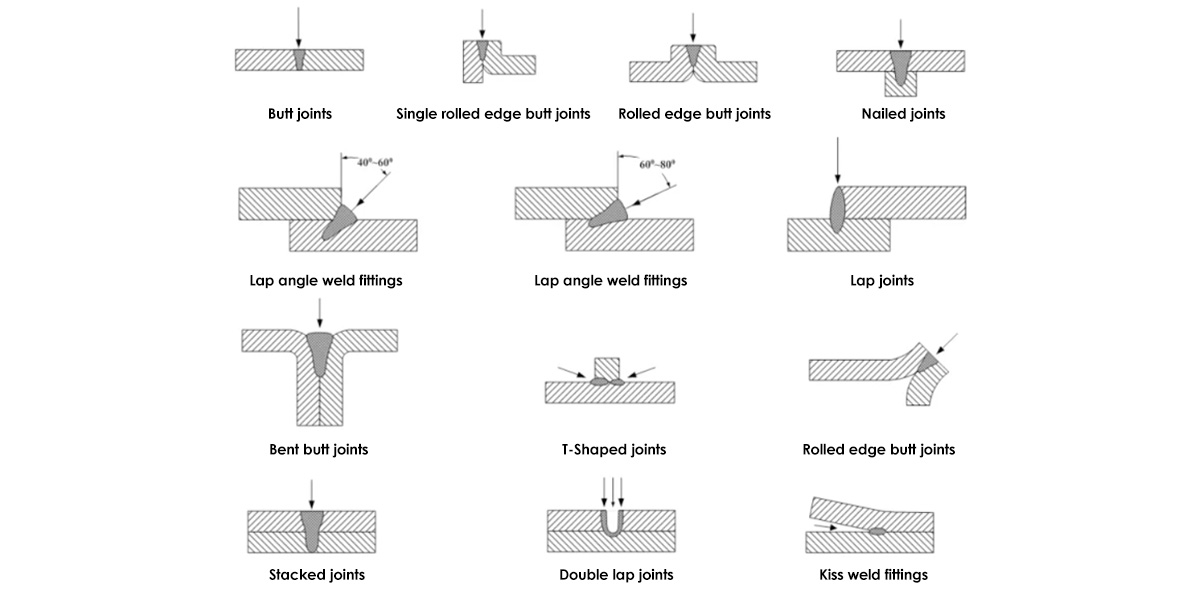

Welding method

A variety of welding methods: It can realize welding at any angle, such as stack welding, butt welding, vertical welding, flat angle welding, internal angle welding, external angle welding, etc. It can weld all kinds of workpieces with complex weld seams and non-regular shapes of larger workpieces.

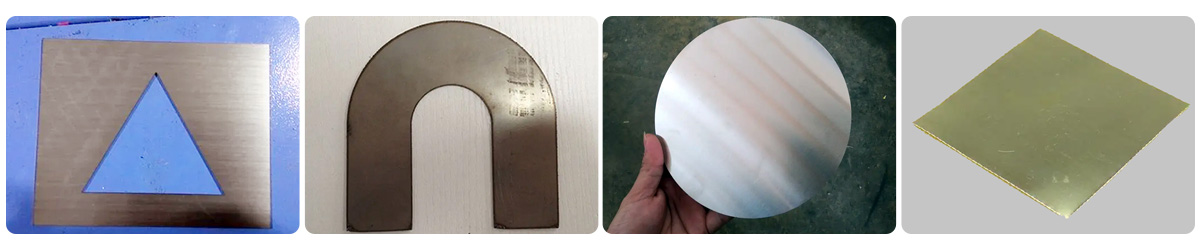

Application materials

Suitable for stainless steel, carbon steel, copper, aluminum, gold, silver, chromium, nickel, titanium and many other metals and alloys; also can be used for welding between a variety of dissimilar materials.

Application industry

Suitable for all kinds of sheet metal, moulds, chassis, power distribution cabinets, kitchen and bathroom products, all kinds of hardware lighting, advertising signs, door and window frames, handicrafts, household products, food machinery, medical equipment, auto parts and other industries.

Parameters of handheld welding machine

Model | ST-FW1500H | ST-FW2000H | ST-FW300H |

Power | 1500W | 2000W | 3000W |

Welding gun weight | 0.8 | 0.8 | 0.75 |

Max. welding thickness (mm) | ≤3 | ≤5 | ≤8 |

Max. welding seam width (mm) | 5 | 5 | 8 |

Laser type | Fiber laser (Suntop custom 20um welding exclusive) |

Laser detection method | Bluetooth wireless connection, Mobile App Monitoring |

Control panel language support | English, Spanish, German, French, Turkish, Italian, Russian, Vietnamese, Thai, Korean, Japanese, etc. |

Laser wavelength (nm) | 1064+5 |

Suitable welding materials | Carbon steel, stainless steel, aluminum, galvanized sheet metal, brass, iron and other metal materials |

Adapted welding methods | Spot welding, overlap welding, splice welding, fillet welding, lap welding etc. |

Laser power adjustment range (%) | 10-100 |

Cooling method | Advanced water-cooling, dual temperature control and automatic control |

Welding aiming preview method | Built-in Red-Light pointer |

Protection systems | Air pressure sensor and solenoid valve control |

Length of fiber optic cable (meter) | Standard 10 (can be customized 15) |

Welding shielding gas | Argon or nitrogen (air pressure approx. 6-8 bar) |

Working environment | Temperature 5-45 °C /humidity 10-90% |

Other optional support functions | Cleaning + cutting | Cleaning + cutting | Cleaning + cutting + weld bead cleaning |

Max. Cutting thickness (mm) | 1.2 | 1.5 | 2 |

Max. cleaning width (mm) | 40 | 40 | 120 |

Automatic wire feeder type (Universal with TIG wire)

| Single wire feed | Single wire feed | Support both the double wire feed and single wire feed |

Solid wire type (SS, Iron, AL, Brass) | 0.8, 1.0, 1.2, 1.6 | 0.8, 1.0, 1.2, 1.6 | 0.8, 1.0, 1.2, 1.6, 2.0, 2.5 |

Temperature control monitoring alarm | Yes | Yes | Yes |

Main machine consumables | Laser protective lenes, welding nozzles, welding wires |

Machine size (MM) | 686*425*611 | 750*1080*1000 | 750*1080*1000 |

Machine net weight (KG) | 110 | 220 | 240 |

Power supply requirement | 110V / 220V±10%, single phase | 380V±10%, three phase |

Total power consumption (Maximum) | 3500W | 4500W | 7000W |