Details Product Parameters Samples Video

Features of gold laser marking

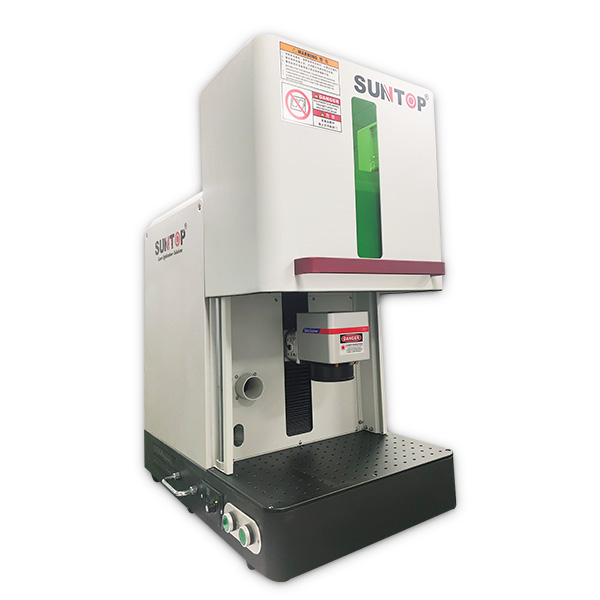

1. Fully enclosed design with European CE standard laser protection glass, visualisation of laser processing, safer operation.

2. High-speed optical oscillator, using German technology laser scanner, marking speed is more than 7000mm/s.

3. CNC full cabinet small laser marking machine is equipped with electric lift focus and emergency stop button, more convenient to use.

4. The machine adopts original control EZCAD control card and software, support two-dimensional and rotary marking, secondary development functions, etc..

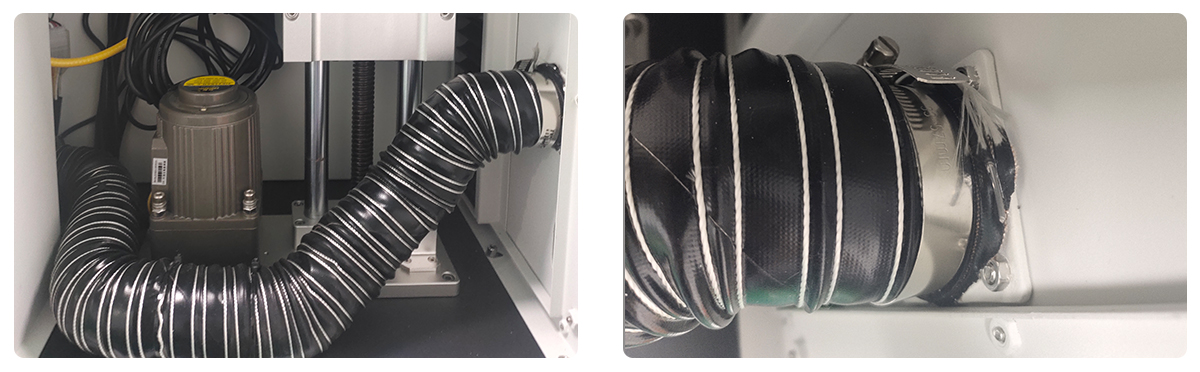

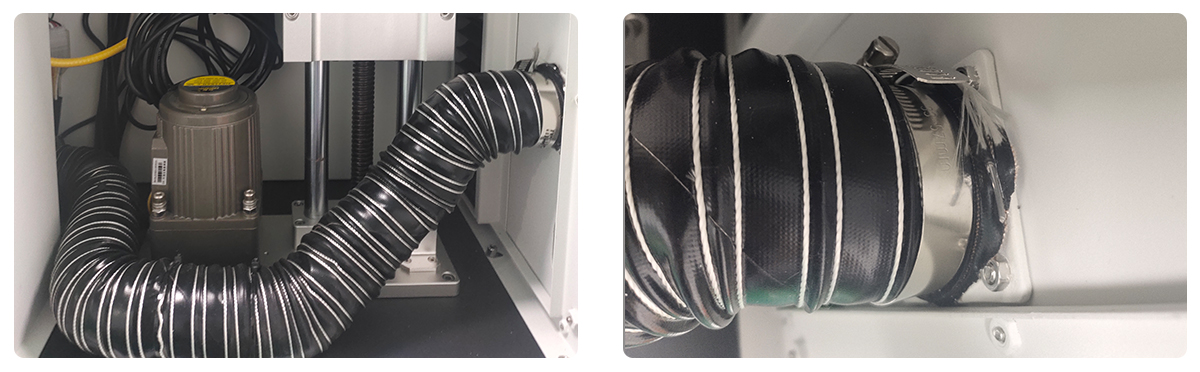

5. The machine is equipped with exhaust and dust removal system, which makes the working environment clean and prolongs the life of optical parts.

Details of gold laser marking

1. Laser Source

Good beam quality, stable performance, long service life (100,000 hours), maintenance-free. Brands such as MAX, Ruike, JPT, etc. can be chosen.

2. Galvanometer Lens

Galvanometer scanning head has good operational stability, high positioning accuracy, fast marking speed, and strong anti-interference capability.

3. Enclosed Protective Cover

Humanized design, enclosed safety cover, flexible adjustment of lifting speed.

4. Work Light

When starting work, the light on the top of the machine turns red.

5. Built-in Air Cooling

Adopting built-in air cooling design for better heat dissipation performance.

Advantages of gold laser marking

Gold laser marking technology in the field of gold craft is of great significance, not only to enhance the product quality and design, but also to promote the innovative development of the industry. With the continuous progress of science and technology, I believe that laser marking technology will show a broader application prospects in the gold process.

Advantage one: high precision marking

Gold laser marking technology can achieve micron-level marking accuracy, ensuring that the details of patterns, text and other details on the gold products are clearly visible, enhancing the grade and added value of the products.

Advantage two: non-contact processing

Laser marking is a non-contact processing method, avoiding the traditional engraving process may cause damage to the gold products, to ensure the quality and appearance of the product.

Advantage three: flexible and diverse design

Laser marking technology can achieve a variety of complex patterns, Logo and other designs to meet the personalized needs of different customers, injecting more creative elements into the gold process.

Advantage four: environmental protection and energy saving

Compared with the traditional chemical corrosion, mechanical engraving and other methods, laser marking technology does not require the use of chemicals, reducing the pollution of the environment, in line with the requirements of modern green production.

Advantage five: production efficiency

Laser marking speed, high efficiency, can realize mass production, greatly reducing the production cycle, improve production efficiency.

Advantage six: durable

Laser marking marking pattern is not easy to wear and tear, fading, with strong durability, making gold products more collection and inheritance value.

Exhaust and dust removal system

The fast and efficient exhaust and dust removal system effectively ensures that the optical lens is not polluted, greatly improves the service life of the optical device, and ensures a thorough cleaning of the working environment.

● The air volume is large and the negative pressure is high, which effectively removes laser smoke and dust.

● Imported high-quality nano flame retardant filter material, high safety and good performance.

● Simple management and maintenance, safe operation, and purification efficiency of 99%.

● Can provide users with system origin solutions.

Application materials of gold laser marking

Suitable for working with most metal marking applications such as gold, silver, stainless steel,

brass, aluminium, steel, Iron titanium etc, and can also mark on many nonmetal materials,such as ABS, Nylon, PES, PVC etc.

Application industry of gold laser marking

Metals, alloy, oxide, ABS, epoxy resin, printing ink, etc, which are widely applying for electronics, jewelry, automobiles, communication products, phone keys, plastic translucent keys, jewelry products, key chain, electronic components, integrated circuits (IC), electrical appliances, buckles cookware, stainless steel products and other industries.

Parameters of gold laser marking

Model | ST-FL20PF | ST-FL30PF | ST-FL50PF |

Laser power | 20W | 30W | 50W |

Depth of single marking | 0.01mm | 0.03mm | 0.06mm |

Same pattern marking efficiency | 10s | 7s | 4s |

Whole machine power | 600W/h | 800W/h | 1000W/h |

Marking area | 70*70mm/110*110mm/150*150mm |

Laser wavelength | 1064nm |

Laser source | MAX Brand(Raycus can be choose) |

Control software | EZCAD |

Cooling mode | Air Cooling |

Working accuracy | ±0.002mm |

Marking speed | 0-7000mm/s |

Repetition frequency | 20-100KHz |

Minimum font for marking | 0.15mm |

Graphic format supported | AI, PLT, DXF, BMP, DST, DWG, DXP |

Working voltage | 220V±10% 50/60 Hz |

Applicable material | All metal (Stainless steel, Carbon steel, Brass,etc.) and some plastic(ABS, PVC,PES, ETC.) |

Net weight/gross weight (KG) | 55KG / 85KG |

Machine dimension | 750*530*910mm (L*W*H) |