|

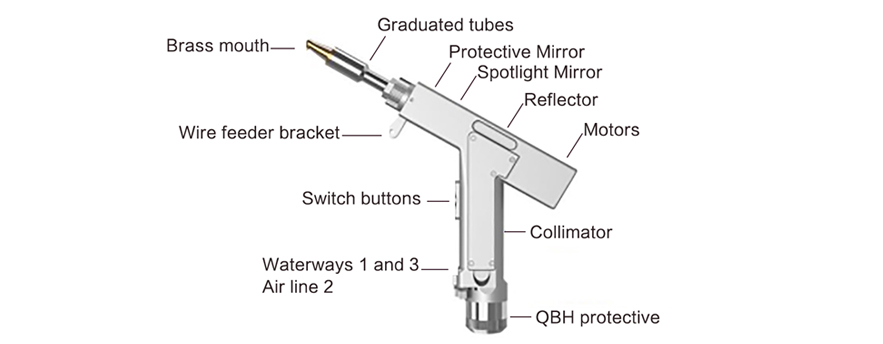

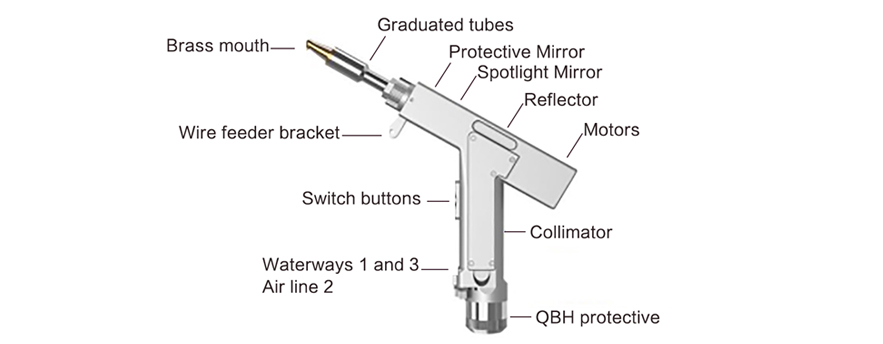

Handheld Welding Head

Features:

- Independently researched and developed with multiple security alarms, allowing for simple and flexible operation.

- Weighing only 0.8kg, it is compact and ergonomically designed.

- Visualize all parameters and monitor the status of the entire machine in real-time to prevent issues, facilitate troubleshooting, ensure stable system operation.

- All process parameters can be set and various process effects can be tested flexibly.

|

Touchscreen

Features:

- Embedded with 24 pre-set modes for various materials

- Only 30 minutes of training needed for beginners to operate the welding system

- Beginners can use the pre-set modes to achieve the same high quality, consistent, and neat welding seams as experienced operators

- Pre-set modes include wobble parameters, suitable for wider welding seams and high tolerance for workpiece assembly fit up

- Advanced operators can create and store additional process modes for different materials and thickness combinations.

|

Automatic Wire Feeder

Features:

- Automatic wire feeding: It can automatically feed the welding wire into the welding gun, which improves the welding efficiency and reduces the labor intensity of workers.

- Stability: It can stably provide a constant welding wire speed to ensure the stability and consistency of welding quality.

- Flexible adjustment: The wire feeding speed, wire feeding length and wire feeding method can be adjusted to meet different welding needs.

- Versatility: Equipped with wire reels of various wire specifications, it is suitable for welding of various types and thicknesses of workpieces.

- Friendly interface: It has a user-friendly interface design, which is simple and convenient to operate and easy to master.

- High precision: The high precision of the welding wire supply can ensure the stability and accuracy of the welding wire during welding.

- Good durability: Made of wear-resistant materials, it has a stable structure and a long service life.

- High safety: Safety protection devices ensure the safety of operators.

|

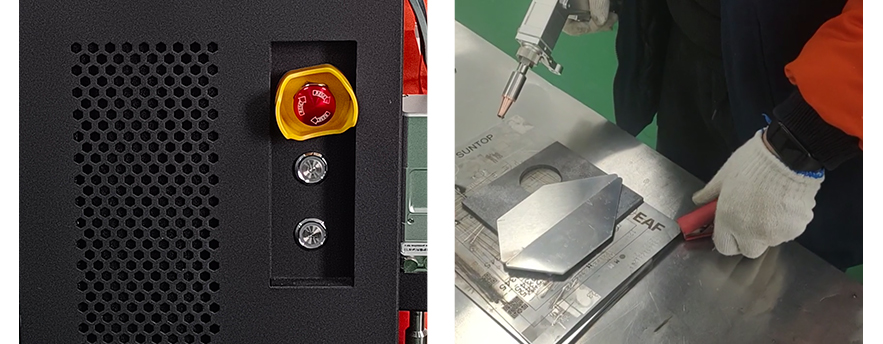

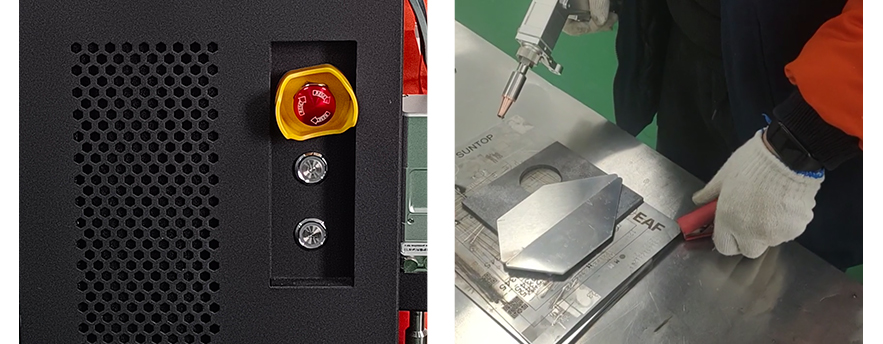

Operator Safety Features

Features:

Air-cooled handheld laser welding equipment has multiple safety protection functions.

Built-in features include:

- Equipped with key switch and emergency stop button to ensure the safety of operation.

- Fiber laser interlock to verify the integrity of laser delivery to the welding gun.

- Part contact electrical interlock to turn off the laser power if the welding head is not in contact with the welded parts.