Details Product Parameters Samples Video

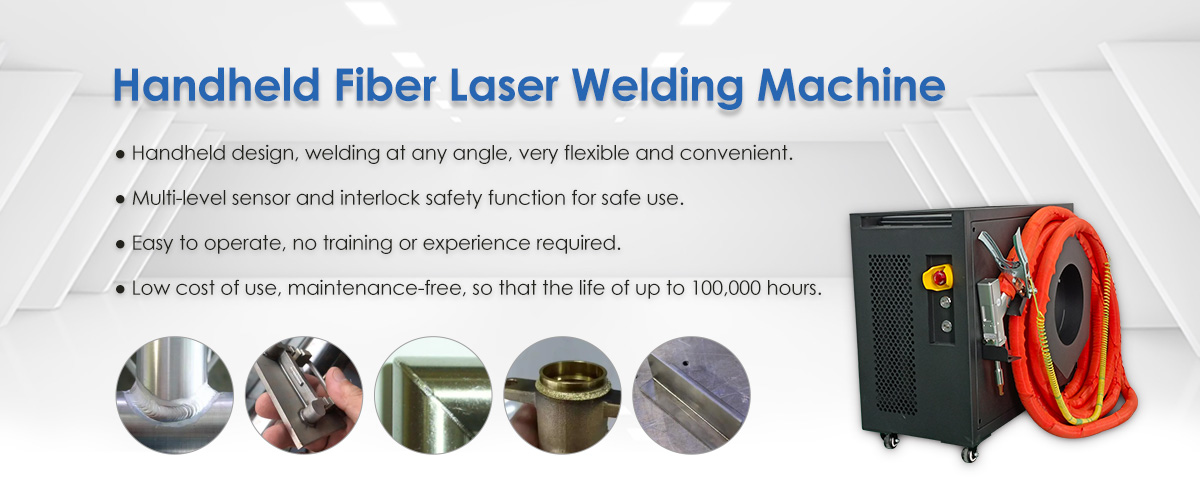

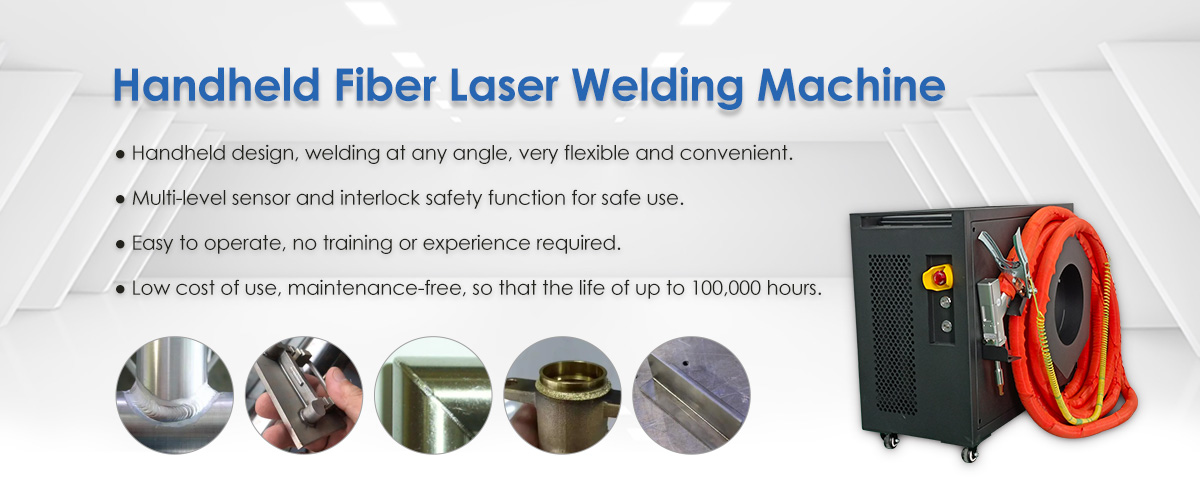

Features of air-cooled handheld laser welding machine

● Embedded with 24 pre-set modes for various materials.

● Only 30 minutes training needed for beginners to operate the welding system.

● Beginners can use the pre-set modes to achieve the same high. quality, consistent and neat welding seams like experienced operators.

● Pre-set modes include wobble parameters, suitable for wider welding seams and high tolerance for workpiece assembly fit up.

● For advanced operators, additional process modes for different materials and thickness combinations can be created and stored.

Details of air-cooled handheld laser welding machine

1. Laser welding head

Lightweight only 0.8KG, flexible and easy to weld any shape of metal parts, Adjustable weld seam width, up to 10-meter length distance welding. With security monitoring systems.

2. Operation interface

Advanced resistive touch screen, supports saving multiple sets of welding parameter libraries and multi-language selection, flexibility, convenience and high efficiency.

3. Auto feeder system

Touch screen design, Automatic wire filler, fully digital design, supports 0.8mm, 1.0mm, 1.2mm, 1.6mm and 2.0mm diameter stainless steel and aluminum wires.

4. Laser Source

We use the customized 45um core diameter welding version fiber laser with a life span of 100,000 hours, maintenance free and can weld all kinds of metals.

5. Built-in air cooling

Unique air-cooled design, low power consumption, energy saving and environmental protection.

6. Welding connection fiber optic

Using 10 meters of original long fiber optic cable, an integrated cable drum is used to store the cable, making the machine more compact when stored or transported.

Advantages of air-cooled handheld laser welding machine

High Speed: Up to 4X Faster than traditional methods-increased productivity for lower costs-per-part.

High Quality: Consistent welding of thick, thin and reflective metals without distortion, undercut or burn through - minimal heat affected zone.

Easy to use: No need training, simple setup, easy to learn and operate, consistent high quality welding.

Enhanced material capability: Metals of different thicknesses, ultra-thin parts, brazing, low and high conductivity materials.

Wobble welding: Up to 5mm additional weld width - increases capacity and creates highly aesthetic seams.

Operator Safety: Multi-level sensors and interlock safety features.

Small size: Thanks to the advanced air cooling system which adapts phase change heat conduction technology, it weighs only 39KG and the volume is <0.1m3.

Single side weld thickness

Maximum melting | 1500W | 2000W |

Stainless steel (mm) | 0.5-4 | 0.5-5/6 |

Mild steel (mm) | 0.5-4 | 0.5-6 |

Aluminum (mm) | 0.5-3 | 0.5-4 |

Brass/copper (mm) | 0.5-1.5 | 0.5-2 |

Galvanized sheet (mm) | 0.5-3 | 0.5-4 |

Iron (mm) | 0.5-4 | 0.5-6 |

Remark: Double weld thickness can be achieved if the material is welded from both sides in two times

Safety features

ST-FWA1500/2000 is a Class IV laser system and routine precautions are required for the safe operation of the equipment.

Built-in features include:

● Key switch control of laser source and Emergency-stop button ensure deliberate operation.

● Fiber laser interlock verifies integrity of laser delivery to the welding gun.

● Laser weld gun trigger, enable and then fire, for intentional operation.

● Part contact electrical interlock turns off the laser power if the welding head is not in contact with the welded parts.

Operators must wear all recommended personal protective equipment (PPE), including laser safety glasses, laser and heat resistant gloves, hats, leather aprons, etc., and other laser and heat resistant clothing.

Application materials of air-cooled handheld laser welding machine

Suitable for stainless steel, carbon steel, copper, aluminum, gold, silver, chromium, nickel, titanium and many other metals and alloys; also can be used for welding between a variety of dissimilar materials.

Application industry of air-cooled handheld laser welding machine

Suitable for all kinds of sheet metal, moulds, chassis, power distribution cabinets, kitchen and bathroom products, all kinds of hardware lighting, advertising signs, door and window frames, handicrafts, household products, food machinery, medical equipment, auto parts and other industries.

Parameters of air-cooled handheld laser welding machine

Model | ST-FWA1500 | ST-FWA2000 |

Power | 1500W | 2000W |

Beam quality | ≤1.2 M⊃2; | ≤1.3 M⊃2; |

Laser wavelength | 1080nm |

Light exit mode | QCW /PWM /CW |

Max modulation frequency | 1000HZ |

Output power stability | <3% |

Aiming positioning system | Built-in Red Light |

Terminal type | QBH |

Delivery cable length | 10M (can be customized) |

Power supply | AC220V±10%,50/60Hz |

Cooling system | Built-in air cooling |

working environment | Temperature 5-45 °C /humidity 10-90% |

Applicable material | Almost all metal materials such as carbon steel, stainless steel, aluminum, brass and galvanized sheet. |

Machine weight | 39KG |

Machine size | 276*667*542mm |