Details Product Parameters Samples Video

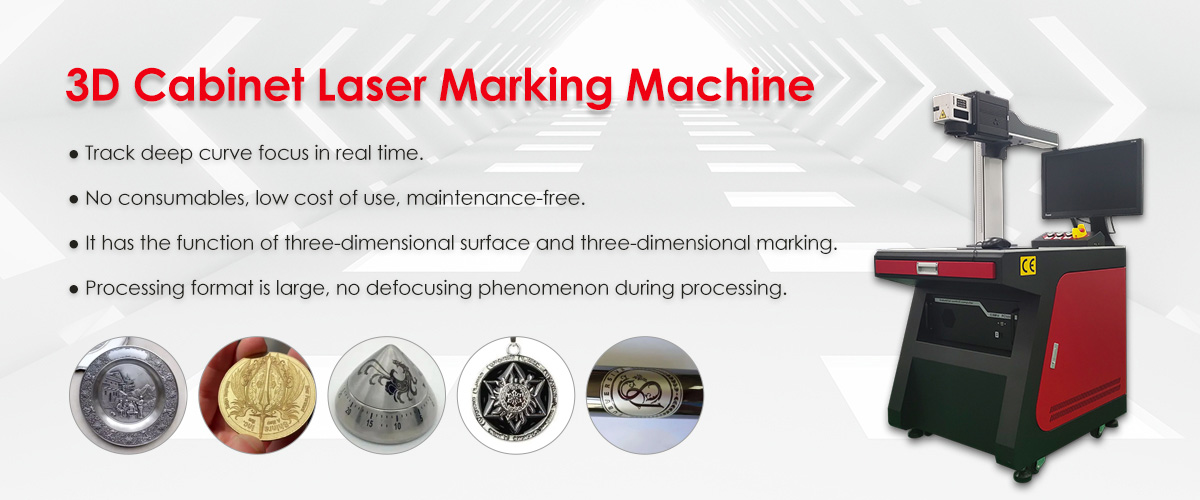

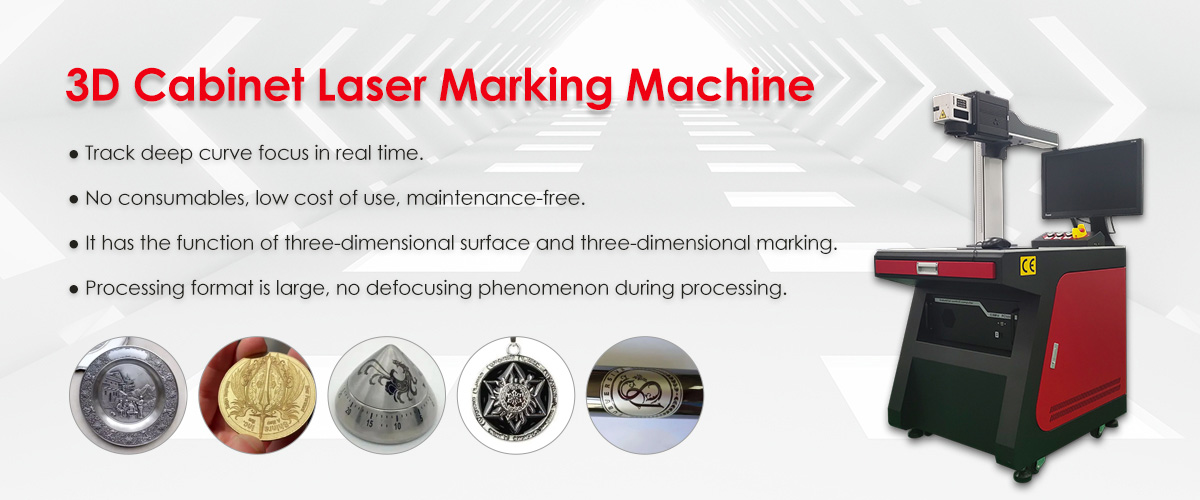

Features of 3d dynamic focusing fiber laser marking machine

1. Equipped with professional 3D scanning lens and automatic control system.

2. Adopt multi-axis dynamic zoom technology to track the focus of deep curves in real time. It can complete flexible and diverse processing requirements, such as curved surface marking, deep engraving and large flat marking.

3. Using 3D fine marking system software, it can meet various manual carving needs, such as relief patterns, deep carvings, negative carvings, etc., which improves the three-dimensional beauty of details.

4. With the function of three-dimensional curved surface three-dimensional marking, it can focus on fine light spots within the relative height standard of 0~60mm dimensional tolerance, and symmetrically mark. Marking of irregular products such as curved surfaces, slopes, steps, spheres, cylinders, cones, etc. without zooming.

5. With large-format marking function, the marking area reaches 800mm * 800mm, breaking through the traditional fiber marking machine marking area limit.

6. Software powerful, can import the mainstream three-dimensional design software output graphics, and can be simple three-dimensional graphics editing, with two-dimensional graphics to three-dimensional function, simple and convenient operation.

7. Support X, Y, Z axis control, automatic processing control.

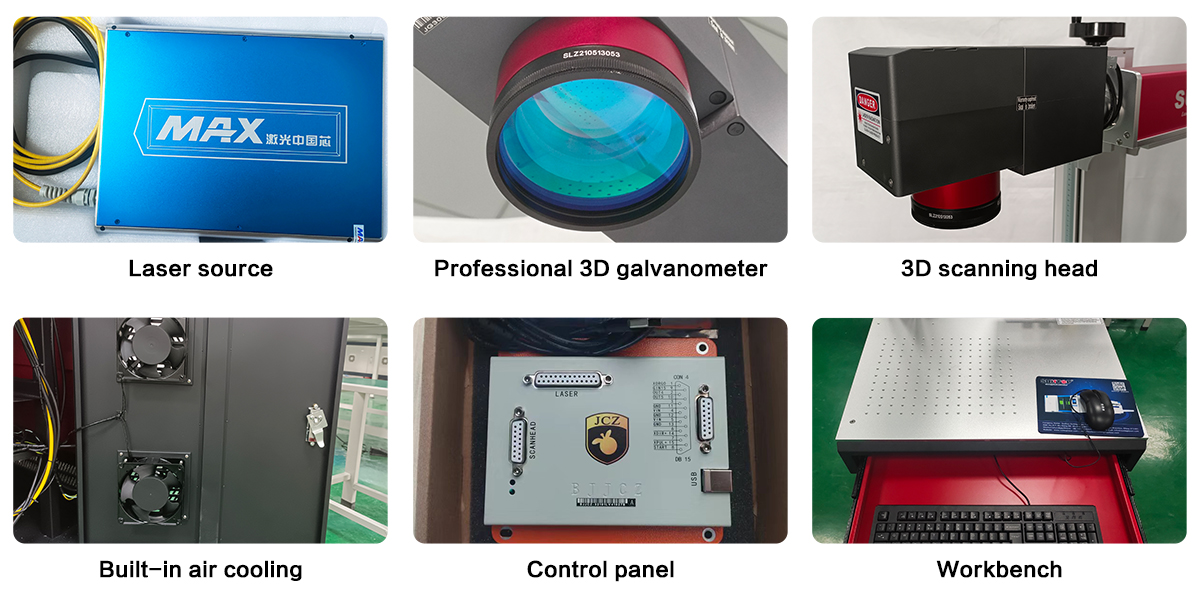

Details of 3d dynamic focusing fiber laser marking machine

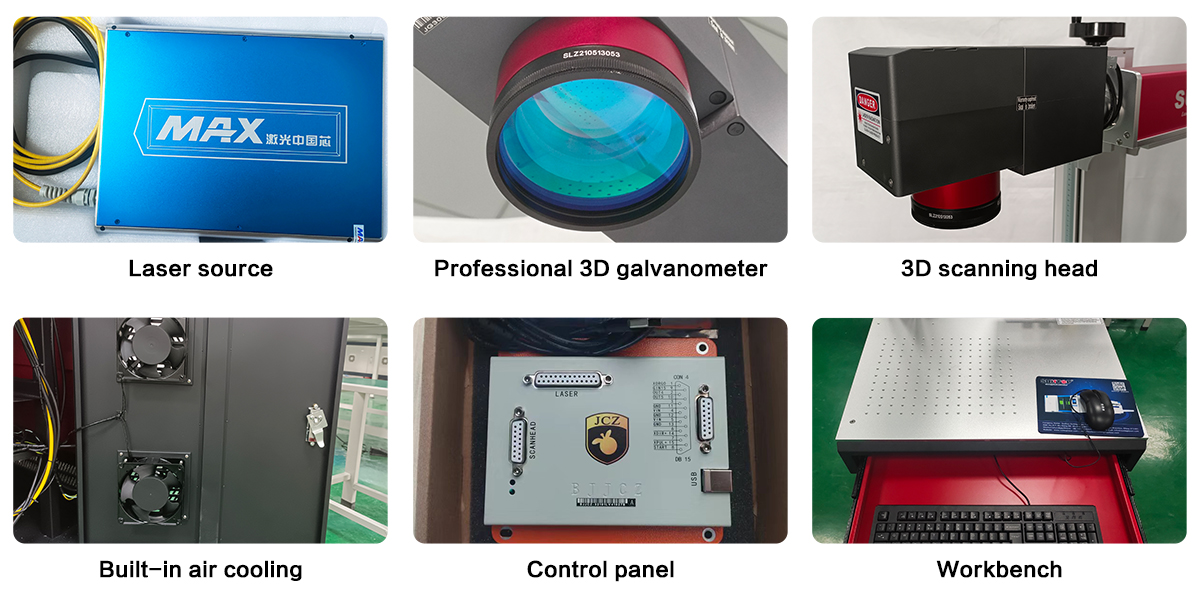

1. Laser source

Adopt famous brand Raycus / JPT / MAX / IPG laser, with excellent beam quality, stable light output, fine spot and strong focusing effect.

2. 3D digital scanning head

Adopt famous brand SINO-GALVO scanning head, high marking speed and high precision. x, y, z-axis, irregular/surface marking, z-axis can move flexibly and automatically.

3. Professional 3D vibrating mirror

Variable focal length, precise control of focal position, ensure focal size and spot quality to realize the engraving of irregular products.

4. Control card

EZCAD control system, hardware processing data fast and high precision, support high speed and high precision marking function.

5. Workbench

The use of all-aluminum operating table, humanized design, multi-positioning arrangement, compact interface, flexible adjustment of product position workers, easy to use.

Advantages of 3d dynamic focusing fiber laser marking machine

1. The spot quality is good, the focused spot is small, and the energy density is high, which is suitable for precise and fine marking.

2. Deep engraving, embossing, curved surfaces, irregular surfaces and materials of different heights can be marked.

3. Stable performance of the whole machine, maintenance-free, long service life, up to 100,000 hours or more.

4. high efficiency of electro-optical conversion, reaching more than 30%, low cost of use, energy saving and power saving.

5. Fast marking speed, high precision, clear and permanent, no fading, no falling off, not easy to be copied and changed.

6. Applicable to various graphic surfaces, three-dimensional graphics such as plane (incline, step difference), cylinder, cone, spherical surface and arbitrary curved surface.

Functions of 3d dynamic focusing fiber laser marking machine

● Overturn the traditional 2D marking mode. It can carve many different 3D shapes, such as: slopes, cylinders, cones, balls, etc. Realize all-round marking.

● The marking software can import graphics exported by mainstream 3D software, and make simple edits to the graphics. Easy to operate.

● Automatically calculate radians and automatically adjust focus. It can mark multi-level large format, three-dimensional surface, plane, etc.

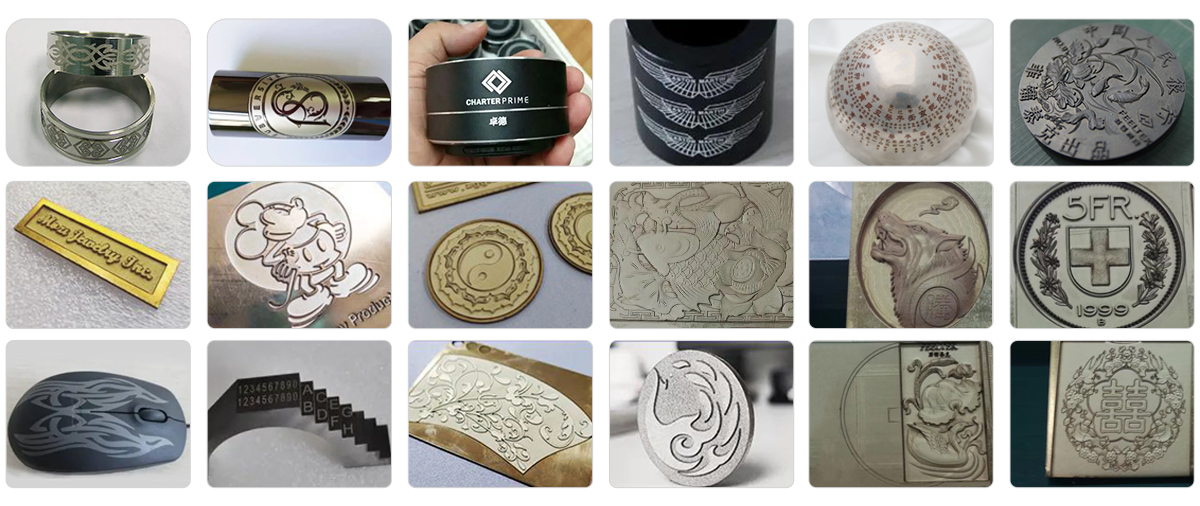

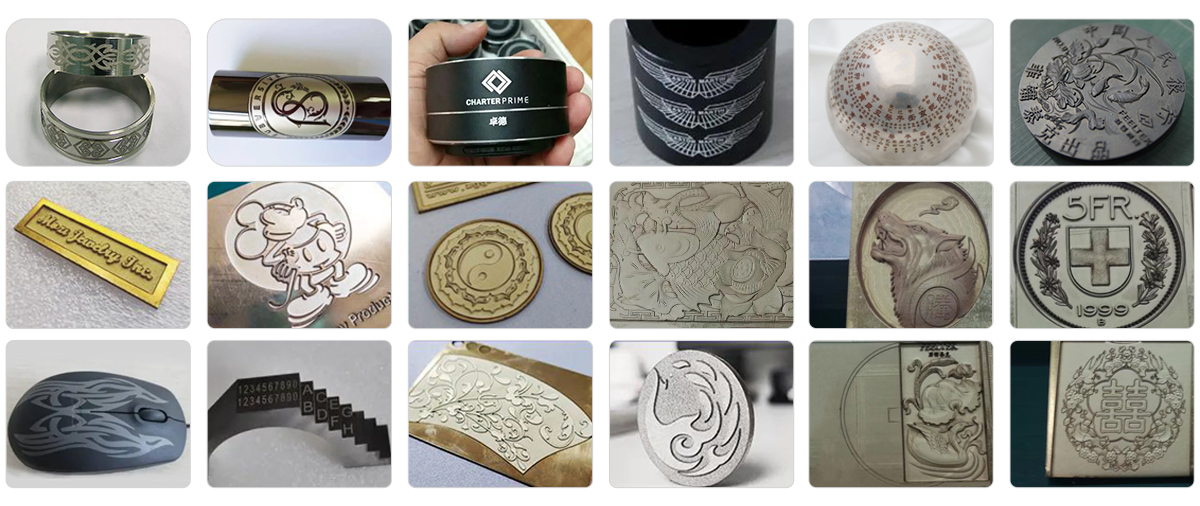

3d dynamic focusing fiber laser marking machine application

Application materials

Suitable for working with most metal marking applications such as Gold, Silver, Stainless Steel, Brass, Aluminium, Steel, Iron Titanium etc, and can also mark on many nonmetal materials,such as ABS, Nylon, PES, PVC etc.

Application industry

Widely used in integrated circuit chips, computer accessories, industrial bearings, clocks and watches, electronic and communication products, aerospace devices, various auto parts, home appliances, hardware tools, molds, wires and cables, food packaging, jewelry, tobacco and military affairs, etc. Marking of graphics and text in the field, as well as mass production line operations.

Parameters of 3d dynamic focusing fiber laser marking machine

Laser Power | 30W | 50W | 60W | 100W |

Model | ST-FL30-3D | ST-FL50-3D | ST-FL60-3D | ST-FL100-3D |

Max Marking Range | 110*110mm/175*175mm/300*300mm/600*600mm/800*800mm |

Laser Wavelength | 1064nm |

Pulse Energy | 1MJ |

Repetitive Frequency | 30K-500KHZ |

Indicator Laser | Red light 655nm/output 1.0 mW |

Minimum Line Width | 0.03mm |

Marking Speed | ≤10000m/s |

Operating System | Windows XP/7/8/10 |

Font Support | Ture type, AUTOCAD Single line font, custom |

One-dimensional Barcode | CODE39/CODE128/ITF/CODABAR/EAN/UPC |

Two-dimensional Barcode | QR/PDF417/Data matrix (ECC200) etc. |

File | PLT/DXF/DWG/SVG/STL/BMP/JPG/JPEG/PNG |

Environmental Requirements | Temperature: 10-35℃, Humidity: 5-75% |

Spare Parts Come with the Machine | Protective glasses, Metal business card, Foot switch, Hex socket wrench, Power cord |

Optional Accessories to Purchase | D80 Rotating Shaft/ D57 Small Chuck/2D Table (X.Y direction)/ Cutting Fixture |

Power supply | 220V±10% 50/60 Hz |

Net Weight (KG)/ Gross Weight | 140KG / 168KG |

Machine Dimension | 1050*800*1200mm (L*W*H) |