Details Product Parameters Samples Video

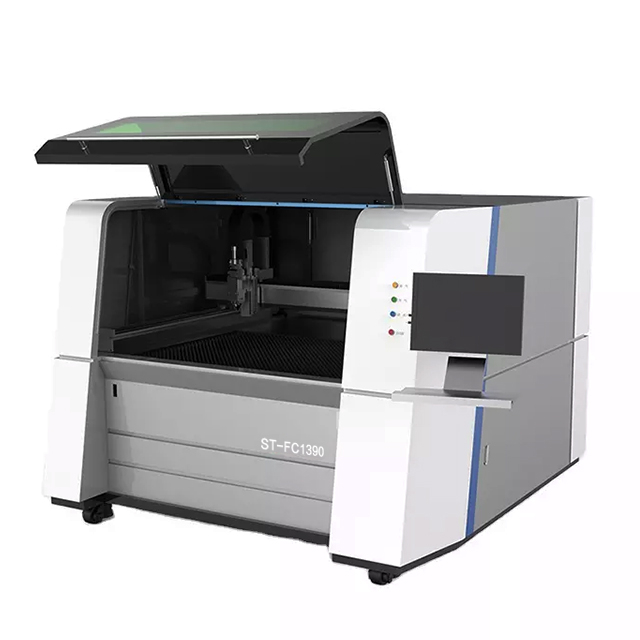

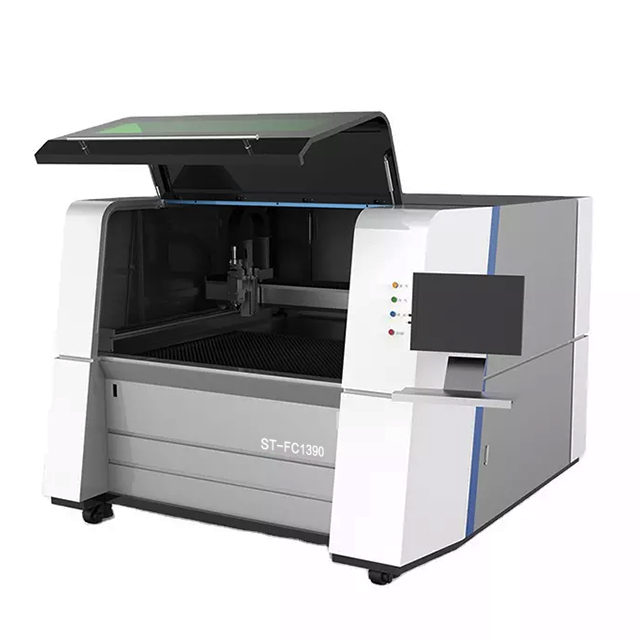

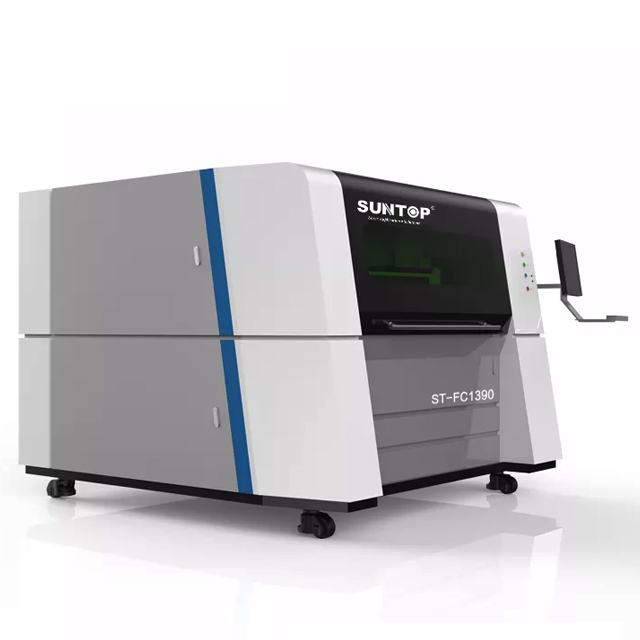

Product features of small size precision laser cutting machine

● Fully enclosed design, with laser protection function, in line with European CE standards.

● Imported servo motors and precision guide rails ensure high cutting precision, stability and longer life.

● High precision, more suitable for precision parts processing and cutting of various fine handicrafts.

● High performance, fiber laser with original imported packaging, stable performance and lifespan of more than 100,000 hours.

● Fast cutting speed, high work efficiency and high stability.

● The kerf is small, the deformation is small, the cutting surface is smooth, flat and beautiful, and there is no need for post-processing.

● Special software can design or process graphics or text in real time. Flexible and easy to operate.

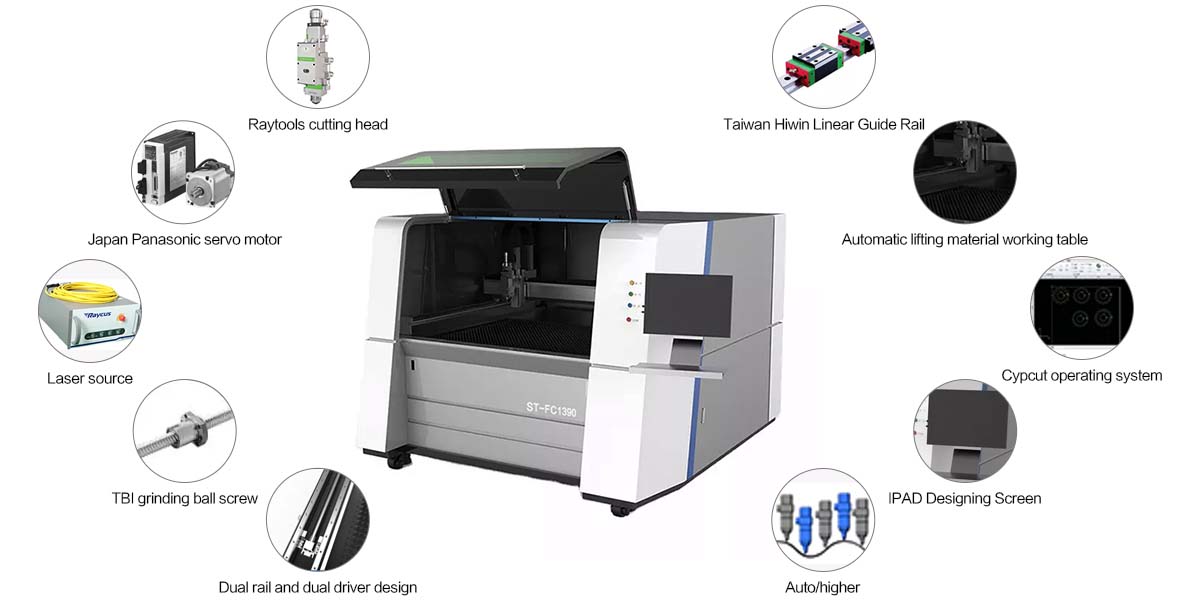

Machine details of small size precision laser cutting machine

1. Raytools cutting head

Automatically adjust the focusing lens to realize automatic punching and cutting of plates with different thicknesses.

Anti-collision design, height adjustment high sensitivity.

2. Japan Panasonic servo motor

High precision, high speed, high stability.

Strong timeliness and short dynamic response time.

Good comfort, less heat and less noise.

3. Laser source

The service life of 100,000 hours is more stable and the cost performance is higher. Raycus, IPG, MAX and other lasers are optional.

4. Dual rail and dual driver design

In order to prevent the deformation of the cutting line caused by the bending of the y-axis screw, the y-axis on both sides is equipped with two-track guide rails and double ball-driven screw design to ensure straightness and arc during high-speed cutting.

5. TBI grinding ball screw

High efficiency, low heat, fast feed, high precision, no gap, high rigidity.

6. Taiwan Hiwin Linear Guide Rail

Adopt Taiwan Hiwin linear guide rail, high positioning accuracy, vortex guide rail, reduce wear and maintain accuracy for a longer time.

7. Automatic lifting material working table

High-precision CNC fixed workbench.

Specially designed small pneumatic wheel carrier, the cut metal sheet can slide along the body for easy loading.

Strip steel workbench; place cutting discs on steel material.

8. Cypcut operating system

Shanghai Cypcut operating system, advanced technology, suitable for cutting various materials.

9. IPAD Designing Screen

Use the high definition toughened glass screen, more exquisite and delicate, the operation is smoother.

10. Auto/higher

The lifting system automatically adjusts the focal length according to the height of the plate.

Advantages of precision laser cutting machine machine tools

The third generation aviation aluminum beam

The gantry is manufactured according to aerospace standards and is extruded with 4,300 tons. After aging treatment, its hardness can reach 6061 T6, which is the strongest among all beams. Aviation aluminum has many advantages such as good toughness, light weight, corrosion resistance, oxidation resistance, low density, and greatly improved processing speed.

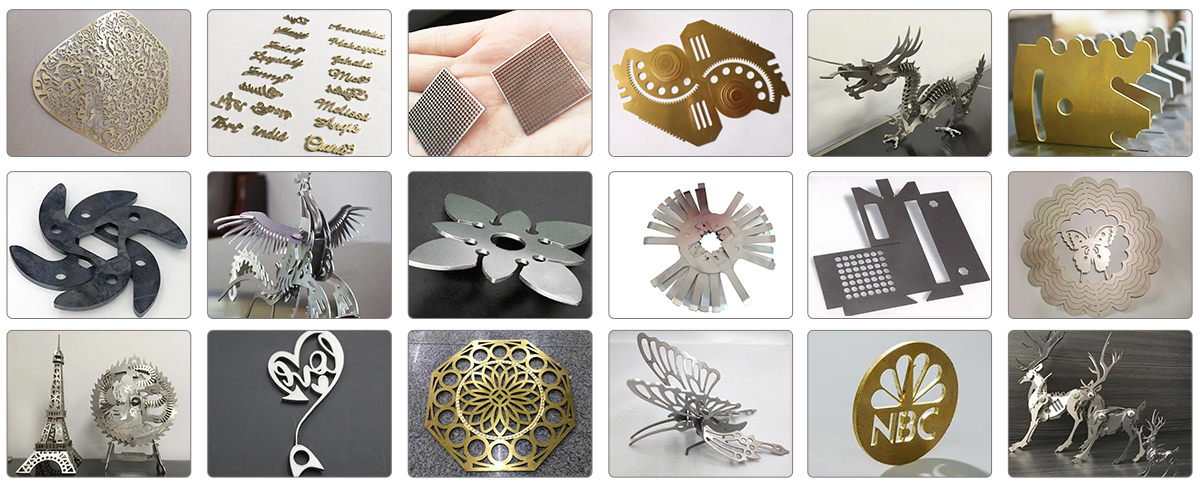

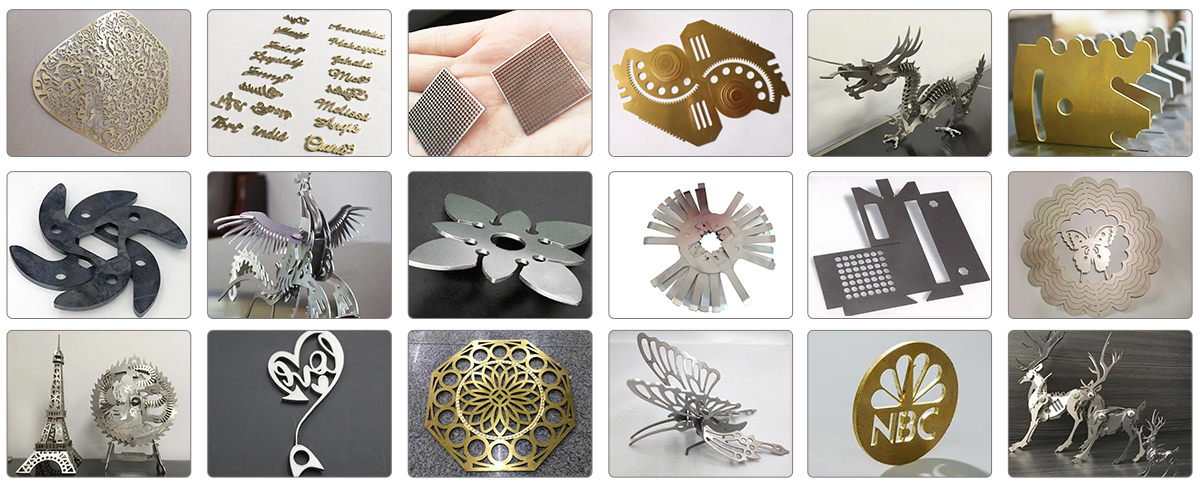

Precision laser cutting machine application

Application materials

Stainless Steel Sheet, Mild Steel Plate, Carbon Steel Sheet, Alloy Steel Plate, Spring Steel Sheet, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet, Metal Plat, etc.

Application industry

Manufacturing Billboard, Advertising, Signs, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal Crafts, Metal Art Ware, Elevator Panel Cutting, Hardware, Auto Parts, Glasses Frame, Electronic Parts, Nameplates, etc.

Parameters of small size precision laser cutting machine

Model | ST-FC1390 |

Table Max. cutting size | 1300*900mm |

Laser power | 1000W, 1500W, 2000W, 3000W, 4000W |

Cutting thickness | 0.5-20mm (depend on the actual laser power) |

Repeat positioning accuracy | ±0.01mm/m |

Maximum operating speed | 40m/min |

Laser type | Fiber Laser |

Laser source | Raycus Brand (MAX, IPG can be choosed) |

Cooling mode | Water Cooling |

Maximum acceleration | 0.5G |

Laser wavelength | 1064nm |

Transmission | High precision screw guide transmission |

Graphic format supported | AI, PLT, DXF, BMP, DST, DWG, DXP |

Working voltage | 220V±10%, 50-60Hz / 380V±10%, 50-60HZ |

Applicable material | All metal (stainless steel, brass, aluminum, titanium steel, etc) |

Machine weight | 1800KG |

Machine dimension (L*W*H) | 2160*2112*1630mm |

Precision laser cutting machine samples