-

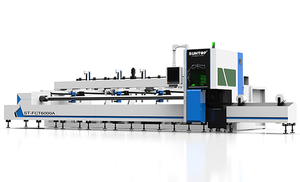

Heavy-duty machine tool Main parts adopt the imported brand; Europe CE standard design; can be equipped with full automatic loading and unloading system; Max. laser power up to 20000W.

-

Fiber laser cutting machine is a laser processing solution that is professionally used in metal processing, aerospace, electronic appliances, home appliances, elevators, automobiles, advertising, precision accessories, craft gifts and other manufacturing industries. The equipment is designed with a gantry double drive structure, which is dual gear rack and dual servo motor drive system with high-speed arc cutting function, that can effectively meet the application requirements of metal materials such as carbon steel, stainless steel, aluminum plate, galvanized sheet, etc.

Product Model: ST-FC3015/ ST-FC3013/ ST-FC4020/ ST-FC6015/ ST-FC6025/ ST-FC12025

Laser power: 1000W-20KW

Working area: 3000*1500mm (3000*1300mm/ 4000*2000mm/ 6000*1500mm/ 6000*2500mm/ 12000*2500mm)

-

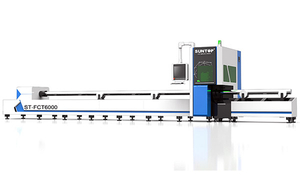

The pipe laser cutting machine adopts a rack and pinion transmission structure, a pneumatic clamping chuck, and a rotating and advancing pipe cutting method, with high centering accuracy and processing accuracy. Cut square tubes, round tubes, rectangular tubes and various special-shaped tubes. The cutting speed is fast and the precision is high, and it can realize the precise cutting of opening, cutting, intersecting lines and various special-shaped complex graphics that are difficult to achieve by conventional methods.

Product Model: ST-FCT6000/ST-FCT3000

Laser power: 1000W-20KW

Tubes length: 3 meters or 6 meters (optional)

-

ST-FC1390 fiber laser cutting machine adopts Japanese Panasonic servo motor, double-drive grinding ball screw, Hiwin guide rail, the positioning accuracy of the machine tool can reach 0.008mm, and the cutting acceleration is 0.5G. It has the characteristics of stable laser power, good beam mode, high peak power, high efficiency, low cost, safety, stability, and easy operation.

Product Model: ST-FC1390

Laser power: 1000W, 1500W, 2000W, 3000W, 4000W

Working area: 1300*900mm (support customization)

-

High degree of automation, fast cutting speed, high production efficiency, short product production cycle, no matter it is simple or complex parts, laser can be used to realize a rapid prototyping cutting. It is conducive to the production of various types of small batches of products and the production of large batches of products.

Product Model: ST-FC6060/ST-FC6040/ST-FC1390

Laser power: 1000W, 1500W, 2000W, 3000W, 4000W

Working area: 600*600mm (600*400mm/1300*900mm)

-

Using the latest generation of fiber laser, equipped with a self-developed welding head, to fill the gap in the handheld welding of the laser equipment industry. It has the advantages of simple operation, beautiful weld seam, fast welding speed and no consumables. Welding of metal materials such as thin stainless steel plates, iron plates, galvanized plates, etc., can perfectly replace traditional argon arc welding, electric welding and other processes.

Product Model: ST-FW1500H/ST-FW2000H/ST-FW3000H

Laser power: 1500W/2000W/3000W

Single maximum welding thickness: 0.5-8mm

-

Easy and simple to operate, no need training, smooth and beautiful welding effect, automatic wire filling system, no need second grinding after welding, machine can be equipped with laser cleaning head.

-

Suntop laser 3000W hand-held laser welding machine, equipped with dual wire feeders, can use two different diameters or types of welding wire at a time to improve production efficiency. The weld seam has high quality and no porosity, which can reduce and optimize the impurities in the base metal, and can refine the structure after welding. The welding speed is fast, and the weld seam is smooth and beautiful.

Product Model: ST-FW1500H/ST-FW2000H/ST-FW3000H

Laser power: 1500W/2000W/3000W

Single maximum welding thickness: 0.5-8mm

-

Desktop design, built-in air cooling, small and compact size, designed for spot welding jewelry products, laser power 150W. Mainly used for welding of thin materials and precision parts. It can realize spot welding, butt welding, seam welding and sealing welding. Its advantages are high positioning accuracy and easy robotization.

Product Model: ST-WY150

Laser power: 150W

-

Portable laser cleaning machine, with the advantages of high efficiency, fast, low cost, the heat load and mechanical load generated on the substrate is small, cleaning for non-damage; waste can be recycled, no environmental pollution; safe and reliable, does not damage the health of the operator; can remove a variety of different thicknesses, different ingredients of the coating; cleaning process is easy to achieve automatic control, to achieve remote control of cleaning from a distance, etc.

Product Model: ST-FC1000H/ST-FC1500H/ST-FC2000H

Laser power: 1000W/1500W/2000W

Working area: 170*170mm/250*250mm/300*300mm

-

Handheld laser cleaning machine is a new generation of surface cleaning high-tech products. Easy to install, control and automate. Easy to operate, turn on the power, you can carry out chemical-free, media-free, dust-free, water-free cleaning, manual adjustment of the focus, fit to the surface cleaning, cleaning surface cleanliness and other advantages.

Product Model: ST-FC1000H/ST-FC1500H/ST-FC2000H

Laser power: 1000W/1500W/2000W

Working area: 170*170mm/250*250mm/300*300mm

-

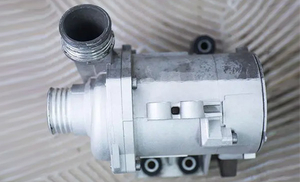

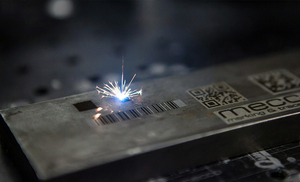

The machine is equipped with our self-developed handheld scanning technology, which facilitates multi-angle marking in a small working environment and is suitable for large equipment and heavy workpieces, such as large metal pipes, car frames, etc. The marking content only needs to be edited on the computer, the handheld marking head is aligned with the marking position and the switch is pressed to achieve rapid marking.

Product Model: ST-FL20H

Laser power: 20W

Working area: 110mm*110mm

-

Our portable fiber laser marking machine adopts the best quality fiber laser source in the world. The estimated life for laser source will be around 100,000 hours, which can use more than 10 years, it's very easy to use, plug and play design, small and compact, light and movable.

-

Fully enclosed laser protection design, electric lift, dust exhaust system. The whole machine is small in size, good in output beam quality, high in reliability, long in service life, high in elector-optical conversion efficiency, and can mark metal materials and some non-metal materials.

Product Model: ST-FL20PF/ST-FL30PF/ST-FL50PF

Laser power: 20W/30W/50W

Working area:70*70mm/110*110mm/150*150mm

-

This laser marking machine is equipped with a computer and a large workbench, suitable for marking large-size products, and can be integrated with a rotating device. It has the advantages of excellent beam quality, high marking accuracy, fast speed and high production efficiency.

Product Model: ST-FL20B/ST-FL30B/ST-FL50B/ST-FL100B

Laser power: 20W/30W/50W/100W

Working area: 110*110mm-600*600mm

-

It adopts European CE standard fully enclosed protective shell. In terms of configuration, it adopts electric up/down function and is equipped with a laser alarm switch. It is used for marking logos, serial numbers, bar-codes and other exquisite patterns. The marking speed is fast, the effect is beautiful, the efficiency is high, and maintenance is free.

Product Model: ST-FL20FB/ST-FL30FB/ST-FL50FB

Laser power: 20W/30W/50W (optional)

Working area: 75mm*75mm/110mm*110mm/150mm*150mm/175mm*175mm/200mm*200mm/250mm*250mm/300mm*300mm

-

Our portable laser marking machine is small in size, easy to carry, low in cost of use, high in precision of marking effect, high in definition, uniform, beautiful in appearance, stable in performance, and has a long service life of the laser, which can be used for more than 10 years.

Product Model: ST-FL20F/ST-FL30F/ST-FL50F/ST-FL100F

Laser power: 20W/30W/50W/100W

Working area:110*110mm/150*150mm/200*200mm/300*300mm

-

CO2 laser marking machine using the famous American brand RF Synard laser generator and high-speed OUYA scanner system to achieve high-speed, high-precision laser marking quality of non-metallic materials.

Product Model: ST-CO2L30P/ST-CO2L60P/ST-CO2L70P/ST-CO2L80P/ST-CO2L1000P

Laser power: 30W/60W/70W/80W/100W

Working area: 200mm*200mm/300mm*300mm/400mm*400mm

-

The whole machine has stable performance, compact structure, small size, light weight, and is easy to carry. The ultraviolet laser focus spot is extremely small, and the processing heat-affected zone is small, so it can perform ultra-fine marking, which is the customer who has higher requirements for marking effect. Preferred product.

Product Model: ST-UV03P/ST-UV05P

Laser power: 3W/5W

Working area: 110*110mm/150*150mm

-

UV laser marking machine has the advantages of short wavelength, short pulse, excellent beam quality, high precision, fast speed, high efficiency, stable performance of the whole machine, low power consumption, and is suitable for high-precision and smooth marking of various materials.

Product Model: ST-UV03/ST-UV05

Laser power: 3W/5W

Working area: 110*110mm/150*150mm