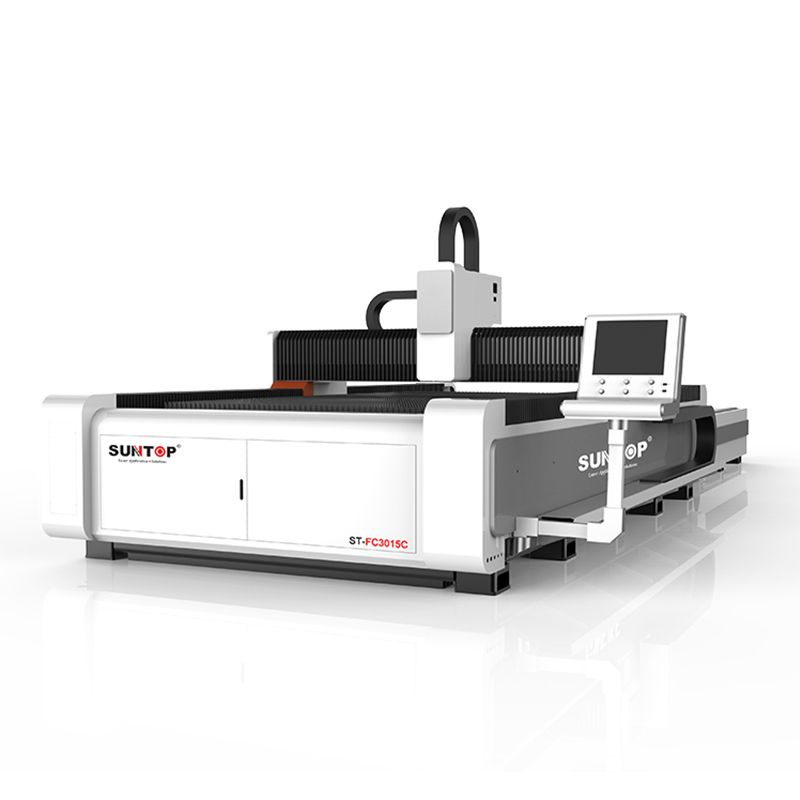

Details Product Parameters Samples Video

Features of laser cut steel machine

1. Adopt parallel exchange platform, double-sided drive with sprocket chain. It has the characteristics of stability, good rigidity and fast speed

2. Equipped with a special laser numerical control system, the machining accuracy is guaranteed under high-speed operating conditions, the production efficiency is high, and the machining accuracy is high.

3. The exchange structure of the workbench and the height design of the saw teeth enable the machine to be equipped with an automatic sheet metal loading and unloading system.

4. The X and Y axes adopt imported gear racks and guide rails, and are equipped with centralized lubrication devices at the same time to ensure long-term stable precision and reliable operation.

5. Double-platform fast exchange system, using well-known guide rails, racks, motors, reducers, etc. as transmission mechanism components, high-speed parallel exchange platform design, can complete the exchange within 10S.

Details of laser cut steel machine

1. Heavy machine tools

The high-power machine tool with hollow structure can effectively reduce the heating area during laser cutting. Long-term use of the machine tool will not deform, but also ensure good cutting accuracy, greatly improving the stability of the machine. It will not be deformed after at least 20 years of use.

2. Cast aluminum beam

It adopts aluminum alloy beam, which has the metal characteristics of light weight and strong rigidity, which is conducive to high-speed movement during processing, and high flexibility is conducive to high-speed cutting of various graphics on the basis of high precision.

3. Suntop patented design universal shaft drive exchange platform

Good synchronization performance, high exchange torque, strong overload resistance, long-term reliable operation without failure. Equipped with high power mid-mounted 3KW motor with brake system and hardened gear reducer, large torque output, symmetrical 80mm diameter universal shaft torque transmission, double 16mm chains to drag the table.

4. Suntop laser cutting head lift (Z-axis)

Adopt closed module, fully sealed and protected, effectively prevent cutting dust and smoke from entering the module, avoid and reduce malfunction. Internal integration of ball screw and linear guide, etc., with high integration, small size and high operating accuracy.

Advantages of laser cut steel machine

1. High-speed parallel exchange platform, double workbench exchange at the same time, stable and reliable transmission mode, shortened exchange time, good frequency converter.

2. The laser head is equipped with an automatic focus function, and the perforation time is reduced by 80% compared with ordinary cutting heads, which is especially suitable for high-speed thick plate cutting and high-reflective material cutting.

3. It has the functions of function detection, automatic diagnosis, fault isolation, automatic fault diagnosis and data display, which can quickly eliminate faults and effectively reduce the cost of after-sales service.

4. Professional laser cutting software, with graphic layout and corner smoothing functions, can realize high-speed drilling and fast cutting functions.

5. Equipped with bus control system, super strong anti-interference ability and superior stability.

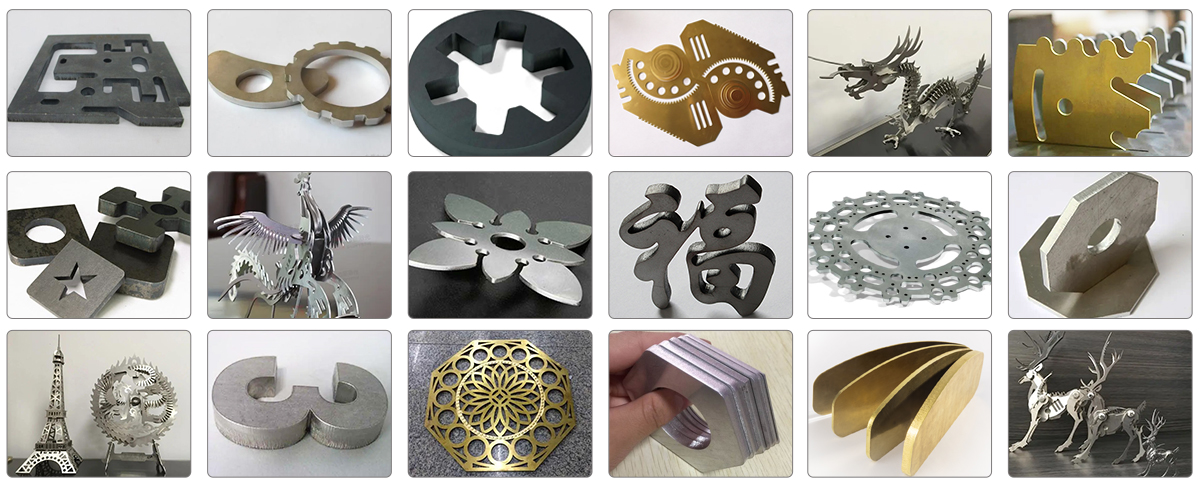

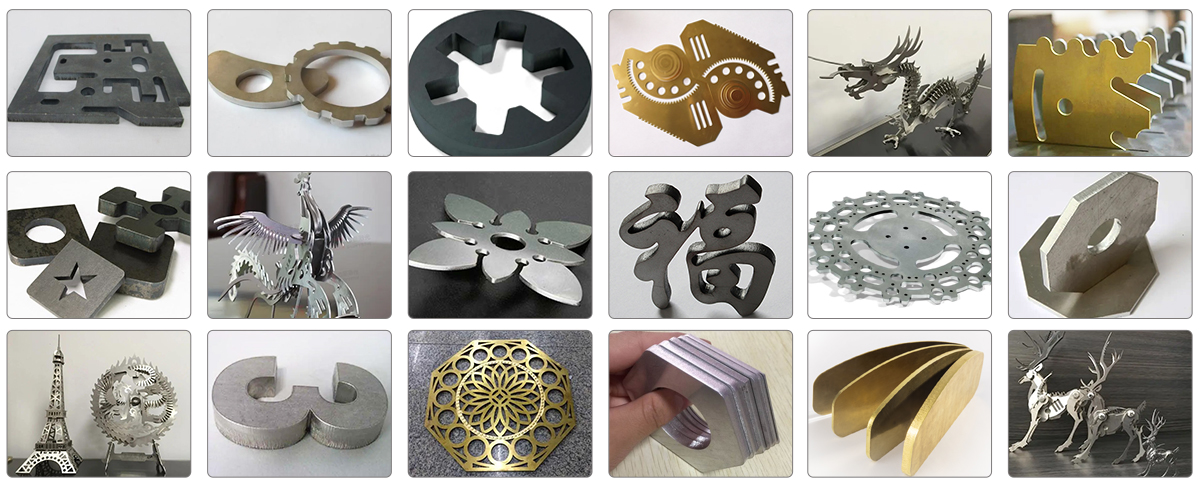

Laser Cut Steel Machine application

Application materials

Suitable for stainless steel, carbon steel, silicon steel, aluminum alloy, titanium alloy, galvanized steel, pickle plate, alumina-plating, zinc plate, metallic copper, brass and other kinds of metals.

Application industry

Widely used in mold laser cutting, electronic applications, aviation, machinery, elevator, automobile, turbine, cutting tool, subway parts, petroleum machinery, food machinery, handicraft, tool processing, decoration, lamp post, steel furniture, decoration, advertising, metal outside processing and other metal related industries.

Parameters of laser cut steel machine

Model | ST-FC3015C/ST-FC4020C/ST-FC6015C/ST-FC6020C |

Laser power | 1000W-20KW |

Table Max. cutting size | 1500*3000mm (4000*2000mm, 6000*1500mm, 6000*2000mm) |

Laser wavelength | 1064nm |

Transmission system | Double rack & pinion and servo drive |

Transmission | High precision screw guide transmission |

Maximum speed | 120m/min |

Repeat positioning accuracy | ±0.02mm |

X.Y axis location accuracy | ±0.01mm |

X.Y axis repeat location accuracy | ±0.01mm |

X.Y axis max moving speed | 30m/min (also according to kind of materials and thickness) |

Cooling mode | Water Cooling |

Maximum acceleration | 0.5G |

Power consumption | <10KW |

Working environment | 0-45℃ ,Humidity ≤ 80%, non-condensing |

Graphic format supported | AI, PLT, DXF, BMP, DST, DWG, DXP |

Working voltage | Three phase 380V/50Hz or 60Hz |

Machine weight | 5000KG |

Machine volume | 37m⊃3; |