Details Product Parameters Samples Video

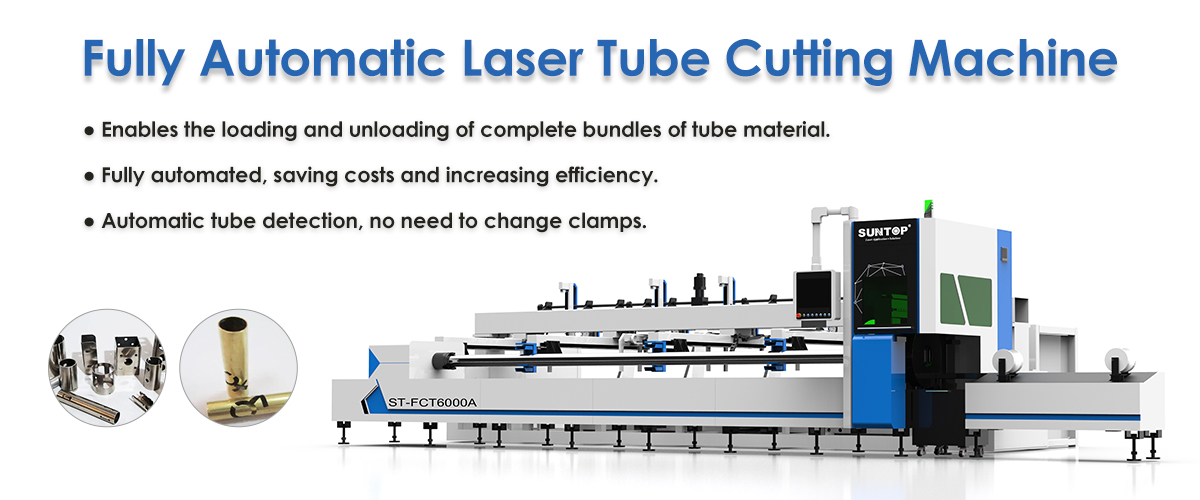

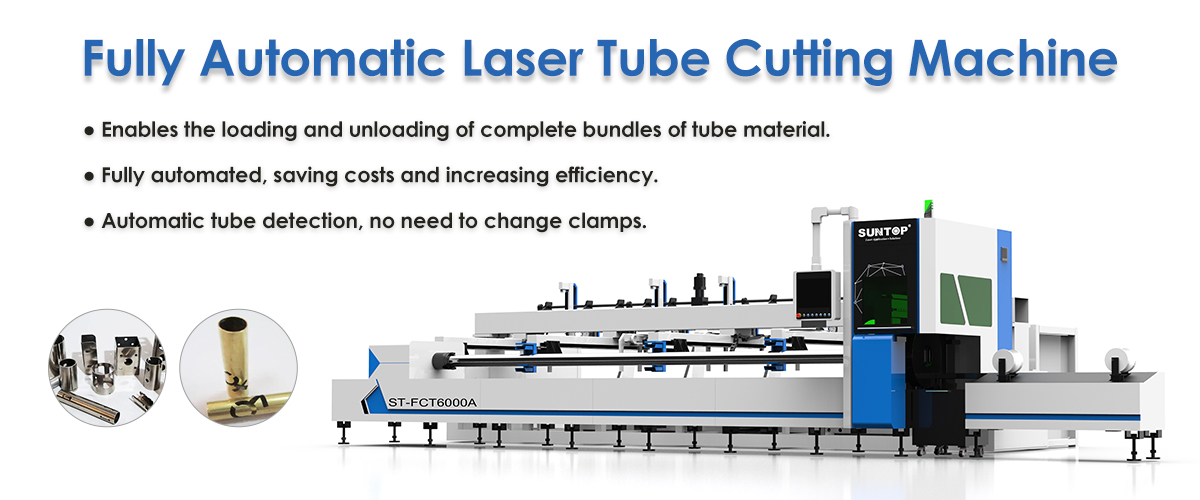

Features of fiber laser cutter pipe

1. Fully automatic bale loading function, reducing the number of operators and improving processing efficiency at the same time

2. The capacitive sensor cutting head has high sensing precision, sensitive response, and the most stable and reliable performance.

3. Unique floating hosting device, while the pipe is fed and rotated, the hosting device is always in contact with the surface of the pipe, and the supporting force is set according to the specification of the pipe to ensure effective support, prevent the pipe from sagging, and reduce the axis swing when the pipe rotates , Improve machining accuracy.

4. The automatic identification system of the pipe section can mix and load various pipe materials, automatically prompt the pipe type, automatically call the process library, and prompt the optional processing formula.

5. The high-precision servo proportional valve precisely controls the air pressure of the cutting auxiliary gas and the clamping force of the chuck to achieve the best cutting effect.

6. The automatic unmanned working cycle, with the help of fast loading and unloading function, makes the machine tool have a high utilization rate.

Details of fiber laser cutter pipe

1. Fully automatic loading and unloading device

Automatic feeding

After the whole bundle of pipes enters the feeding device, it realizes intelligent material separation and feeding, and seamlessly connects with the fiber laser cutting machine to ensure that only one pipe is transported to the conveying arm at a time.

automatic uninstall

The finished product automatically falls into the hopper, and the double support bearing assists in supporting the super long tube.

2. Dedicated laser cutting head

The special laser cutting head for pipes, together with the special cutting system and nesting software, can realize the long-term cutting function of various pipe fittings.

3. Fractional automatic bracket installation

The intelligent pipe support design is adopted to solve the deformation problem during the cutting process of long pipes.

4. Fixture design

There are electric clips designed on both sides, which can be adjusted automatically. The adjustable range of diagonal is 20-200mm.

5. Automatic stroke protection

Detect the whole process of cutting head work, quickly feedback the risk and stop. Fixed limit double protection, improve equipment and personal safety, reduce risks.

Advantages of fiber laser cutter pipe

1. Automatic loading and unloading, double the efficiency and greatly save labor costs.

2. The thermal shock of laser cutting pipe is small, not easy to deform, the cutting surface is smooth and beautiful, and no secondary treatment is required.

3. The cost of laser cutting is very low, almost no consumables, maintenance-free, and the life of the laser generator can reach 100,000 hours.

4. Follow-up support system to realize auxiliary loading and support, improve cutting accuracy.

5. Real-time deviation compensation, convenient clamping of pipes, high precision of pipe perforation and cutting.

6. Strong stability The integral built-in drive structure improves transmission accuracy and stability.

Fiber laser cutter pipe application

Application materials

Suitable for cutting the stainless steel, carbon steel, silicon steel, aluminium alloy, titanium alloy, galvanized steel, pickle steel, aluminium-plating Zinc tubes, metallic copper, brass and other rare metal tubes.

Application industry

It is widely used in laser cutting processing of various metal tubes, such as mold laser cutting, electronic applications, aviation, machinery, elevator, automobile, turbine, cutting tool, subway parts, petroleum machinery, food machinery, handicraft, tool processing, decoration, lamp post, steel furniture, decoration, advertising, metal outside processing and other metal tube related industries.

Parameters of fiber laser cutter pipe

Model | ST-FCT6000A/ST-FCT3000A |

Laser power | 1000W-20KW |

Laser wavelength | 1064nm |

Elector-optical conversion efficiency | 25%-30% |

Cutting thickness | 0.5-30mm (depend on the actual laser power) |

Cutting seam width | 0.1-1.3mm (depend on the actual thickness of metals) |

Repeated positioning accuracy of the machine tool | ±0.02mm/1000mm |

Positioning accuracy of the machine tool | ±0.03mm |

Max. idle moving speed | 100meter/min |

Max. acceleration | 1.2G |

Max. loading weight | 3000KG |

Single pipe Max. weight | 100KG (when air pressure is 6 bar, every meter≤16KG) |

Tailing length | ≥160mm |

Pipe processing range | 20mm≤Round pipe≤210mm, square pipe (20mm-150mm) |

Voltage and frequency | Three phase 380V/50Hz or 60Hz |

Machine weight | 9000KG |

Machine dimension | 12000*2450*2400mm (L*W*H) |